Improving Efficiency with Lean Six Sigma Process Mapping

Lean Six Sigma process mapping offers a structured way to improve workflows by identifying inefficiencies and eliminating waste. It provides a clear visual representation of processes, enabling organizations to pinpoint bottlenecks and redundancies. For example, Bank of America used Lean Six Sigma to evaluate its data warehouse management. The analysis revealed that over 90% of operations were non-value-added. By addressing flaws in its database system, the bank improved data availability by 96 days annually. This approach supports hiring systems, enhances process efficiency, and ensures optimization steps are data-driven and impactful.

Key Takeaways

Lean Six Sigma maps show workflows and find problems easily.

Clear maps help teams work together and understand better.

Using facts makes sure changes are helpful and work well.

Updating maps often keeps work matching company goals.

Involving people early gets support and helps mapping succeed.

Simple maps stop confusion and make them easier to use.

Finding and removing waste saves time and resources.

Always improving helps keep work running great over time.

What Is Lean Six Sigma Process Mapping?

Definition and Purpose

Lean Six Sigma process mapping is a structured approach to visually representing workflows and identifying inefficiencies. It provides clarity on how processes function and highlights areas for improvement. By creating a detailed map of activities, organizations can uncover potential errors, redundancies, and bottlenecks. This method simplifies complex workflows, making them accessible to all stakeholders.

Process mapping serves several purposes:

It creates a clear understanding of business processes for both technical and non-technical audiences.

It identifies defects and inefficiencies, enabling targeted improvements.

It aligns organizational workflows with strategic objectives, ensuring consistency and effectiveness.

Real-world examples demonstrate its impact across industries. For instance, a global electronics company reduced defect rates by 25% after implementing Lean Six Sigma process mapping techniques. Similarly, a retail chain optimized inventory management, achieving a 15% reduction in stockouts and a 10% increase in sales.

How It Combines Lean and Six Sigma Principles

Lean Six Sigma process mapping integrates the principles of Lean and Six Sigma to enhance efficiency and quality. Lean focuses on eliminating waste and streamlining workflows, while Six Sigma emphasizes reducing variability and improving accuracy. Together, these methodologies create a powerful framework for process optimization.

Organizations use this combination to achieve measurable results. For example:

A manufacturing company reduced cycle times and improved product quality, leading to higher profitability and customer satisfaction.

A marketing team visualized campaign workflows, cutting delivery times by 30% and improving coordination.

A tech company employed SIPOC diagrams to enhance communication between development and customer support teams, reducing response times for customer issues by 40%.

This integration ensures that process mapping not only identifies inefficiencies but also provides actionable solutions based on data-driven insights.

Importance of Visualizing Processes for Efficiency

Visual process mapping transforms complex workflows into intuitive models, making them easier to understand and analyze. It enables stakeholders to explore scenarios, evaluate potential optimizations, and identify opportunities for automation. This clarity fosters collaboration and supports informed decision-making.

Statistical evidence highlights the importance of visualization in improving operational efficiency. Organizations that adopt visual process mapping report significant improvements in workflow optimization and resource allocation. For example, automating manual entry processes can reduce entry time by 50%, while simplifying approval layers can decrease cycle times by 30%.

The benefits extend beyond efficiency gains. Process maps promote transparency and accountability, ensuring that all team members understand their roles and responsibilities. They also support continuous improvement by providing a baseline for measuring progress and identifying new areas for enhancement.

Benefits of Lean Six Sigma Process Mapping

Identifying Bottlenecks and Inefficiencies

Lean Six Sigma Process Mapping excels at uncovering bottlenecks and inefficiencies that hinder workflows. By visually representing processes, organizations can pinpoint areas where delays or redundancies occur. For example, in an emergency department, mapping revealed critical points in patient care where information was gathered. Staff focused on specific units, such as the Majors, to improve management and planning, reducing bottlenecks and enhancing care delivery.

Several industries have achieved remarkable results through bottleneck analysis:

Toyota's Production System uses value stream mapping to create smoother workflows and increase throughput.

A pharmaceutical company optimized tablet coating processes, leading to a 25% increase in overall equipment effectiveness.

An automotive parts manufacturer improved throughput by 30% and reduced work-in-process inventory by 20% after identifying bottlenecks.

These examples highlight how process mapping transforms inefficiencies into opportunities for improvement, driving measurable outcomes across diverse sectors.

Enhancing Team Collaboration and Communication

Process mapping fosters collaboration by involving stakeholders in documenting and improving workflows. It creates a shared understanding of processes, enabling teams to work together more effectively. For instance, business process mapping establishes a common language for discussing workflows across departments, breaking down silos and encouraging teamwork.

Evidence Type | Description |

|---|---|

Collaboration | Process mapping encourages collaboration among team members by involving stakeholders in the process documentation and improvement efforts. |

Increased Transparency | Process mapping provides a transparent view of how processes operate, allowing stakeholders to understand the flow of work and make informed decisions. |

Transparency plays a key role in improving communication. When teams can see how their tasks fit into the larger workflow, they gain clarity and alignment. This shared perspective reduces misunderstandings and enhances coordination, ensuring smoother operations.

Supporting Data-Driven Decision Making

Lean Six Sigma Process Mapping empowers organizations to make decisions based on data rather than assumptions. By analyzing workflows, teams can identify inefficiencies and measure their impact quantitatively. This approach ensures that improvements are targeted and effective.

For example, mapping processes in manufacturing revealed areas where cycle times could be reduced. Teams implemented changes that improved product quality and profitability. Similarly, marketing teams visualized campaign workflows, cutting delivery times by 30% and enhancing coordination.

Data-driven insights also support continuous improvement. Process maps provide a baseline for measuring progress, enabling organizations to track the effectiveness of changes over time. This iterative approach ensures that workflows remain optimized and aligned with strategic goals.

Reducing Waste and Optimizing Resource Allocation

Reducing waste is a cornerstone of Lean Six Sigma Process Mapping. By identifying non-value-added activities, organizations can streamline workflows and allocate resources more effectively. Waste often takes many forms, such as unnecessary steps, excessive inventory, or inefficient use of time. Process mapping provides a clear view of these inefficiencies, enabling teams to address them systematically.

For example, a manufacturing company used process mapping to analyze its production line. The team discovered redundant quality checks that added no value to the final product. By eliminating these steps, the company reduced production time by 15% and saved significant labor costs. Similarly, a healthcare provider optimized its patient intake process, cutting wait times by 20% and improving resource utilization.

Organizations can also use process mapping to optimize resource allocation. Visualizing workflows helps teams identify areas where resources are underutilized or overburdened. For instance, a retail chain used mapping to balance staffing levels across stores, ensuring adequate coverage during peak hours while reducing idle time during slower periods. This approach not only improved efficiency but also enhanced employee satisfaction.

Process mapping supports continuous improvement by providing a framework for monitoring resource usage. Teams can revisit their maps regularly to identify new opportunities for optimization. This iterative process ensures that resources remain aligned with organizational goals, driving long-term success.

Promoting Transparency and Accountability

Transparency and accountability are critical for fostering trust and collaboration within organizations. Lean Six Sigma Process Mapping promotes these values by creating a shared understanding of workflows. When processes are visually documented, all stakeholders gain clarity on how tasks are performed and who is responsible for each step.

A study of MeTA programs highlights the impact of transparency in operations. These programs collected and analyzed data on access indicators, enabling informed decision-making. Open stakeholder meetings further increased engagement and accountability. Efforts to embed accountability in policies and procedures institutionalized these practices, ensuring long-term benefits.

Findings | Implications |

|---|---|

MeTA programs collected and analyzed data on access indicators | Enhanced transparency through informed decision-making |

Open stakeholder meetings were held | Increased stakeholder engagement and accountability |

Efforts to embed accountability in policies and procedures | Institutionalized transparency and accountability in operations |

Process mapping also encourages accountability by clearly defining roles and responsibilities. Teams can see how their contributions impact the overall workflow, fostering a sense of ownership. For example, a logistics company used swimlane diagrams to clarify responsibilities across departments. This approach reduced errors and improved coordination, leading to faster delivery times.

By promoting transparency and accountability, process mapping helps organizations build a culture of trust and collaboration. These values not only enhance operational efficiency but also strengthen relationships with stakeholders, paving the way for sustainable growth.

Types of Process Maps in Lean Six Sigma

SIPOC Diagram

Overview and Components of SIPOC

A SIPOC diagram is a high-level process map that outlines the key elements of a process. The acronym SIPOC stands for Suppliers, Inputs, Process, Outputs, and Customers. This tool provides a structured way to define the scope of a process and identify its critical components.

The components of a SIPOC diagram include:

Suppliers: Entities or individuals providing inputs to the process.

Inputs: Resources, materials, or information required to execute the process.

Process: The sequence of steps or activities performed to achieve the desired outcome.

Outputs: The results or deliverables produced by the process.

Customers: The recipients or beneficiaries of the outputs.

When and How to Use SIPOC Effectively

Organizations use SIPOC diagrams during the initial stages of process improvement projects. This tool helps teams gain clarity on the process boundaries and align stakeholders on the objectives. For example, a SIPOC diagram can be used to map the order fulfillment process in a retail business, ensuring that all parties understand their roles and responsibilities.

The table below compares the SIPOC diagram with other process mapping tools:

Tool | Benefits | Applications in Operational Efficiency |

|---|---|---|

Flowchart | Identifies inefficiencies, simplifies processes, establishes documentation | Basic process visualization and training |

SIPOC Diagram | Clarifies stakeholders, outlines process components, sets boundaries | Initial clarity for process improvement projects |

Value Stream Mapping | Visualizes flow, eliminates waste, optimizes efficiency | Lean practices, improving lead time and reducing costs |

Swimlane Diagram | Clarifies responsibilities, shows team interactions | Identifying delays and handoffs in cross-functional processes |

Value Stream Map

Understanding Value Streams and Their Role

A value stream map (VSM) is a detailed process map that visualizes the flow of materials and information through a process. It focuses on identifying value-added and non-value-added activities, enabling organizations to eliminate waste and improve efficiency.

Value streams represent the series of steps required to deliver a product or service to the customer. By mapping these streams, teams can gain insights into the overall workflow and identify areas for improvement.

Benefits of Value Stream Mapping in Lean Six Sigma

Value stream mapping offers several benefits, including improved visibility, reduced lead times, and optimized resource allocation. For instance, Healthfirst, a New York-based health insurance provider, used value stream mapping to enhance their release quality and accelerate deployments. They achieved better visibility into their work, automated governance, and reduced risks.

Teams that adopted value stream mapping identified bottlenecks and improved their operating model. This led to a reduction in lead times for features from 9-12 months to 4-6 weeks, showcasing a significant improvement in product development efficiency.

By focusing on the flow of value, organizations can streamline their processes and achieve measurable results.

Swimlane Diagram

How Swimlane Diagrams Work

A swimlane diagram is a type of process map that divides a workflow into lanes, each representing a specific team, department, or individual. This format clarifies responsibilities and highlights interactions between different stakeholders.

The diagram uses horizontal or vertical lanes to organize tasks, making it easy to identify delays, handoffs, and redundancies. For example, a swimlane diagram can map the customer onboarding process in a financial institution, showing how tasks move between sales, compliance, and operations teams.

Applications in Cross-Functional Processes

Swimlane diagrams are particularly useful for cross-functional processes involving multiple teams. They help organizations identify inefficiencies caused by poor communication or unclear responsibilities. For instance, a logistics company used swimlane diagrams to streamline their shipping process. By clarifying roles and reducing handoffs, they improved delivery times and customer satisfaction.

This tool fosters collaboration and ensures that all stakeholders understand their contributions to the overall workflow.

Detailed Process Map

When to Use Detailed Mapping

A detailed process map provides an in-depth view of every step within a workflow. This type of mapping is ideal when teams need to analyze complex processes or identify specific inefficiencies. For example, manufacturing companies often use detailed mapping to examine production lines. By breaking down each task, they can uncover hidden delays or redundant steps.

Organizations should use detailed mapping when:

Processes involve multiple decision points or handoffs.

Teams need to identify root causes of recurring issues.

Stakeholders require a granular understanding of workflows.

Detailed mapping is especially useful during process improvement initiatives. It allows teams to focus on specific areas that need optimization, ensuring targeted and effective solutions.

Benefits of High-Level vs. Detailed Mapping

High-level and detailed process maps serve different purposes. High-level maps provide a broad overview of workflows, making them suitable for strategic planning. In contrast, detailed maps offer a microscopic view, enabling teams to address operational challenges.

Aspect | High-Level Mapping | Detailed Mapping |

|---|---|---|

Focus | Overview of major steps | Comprehensive breakdown of tasks |

Use Case | Strategic alignment | Operational problem-solving |

Complexity | Simple and easy to understand | Detailed and intricate |

Audience | Executives and decision-makers | Process analysts and team members |

Both types of mapping complement each other. High-level maps set the stage for strategic goals, while detailed maps ensure those goals are achieved through precise execution.

End-to-End Process Map

Visualizing the Entire Workflow

An end-to-end process map captures the entire workflow from start to finish. This comprehensive view helps organizations understand how different components interact. For example, a retail company might use an end-to-end map to visualize the journey from order placement to product delivery.

This type of mapping highlights the flow of materials, information, and tasks across departments. It also reveals dependencies and potential bottlenecks. Tools like flowcharts and value stream mapping are particularly effective for visualizing end-to-end workflows. These tools simplify complex processes, making them easier to analyze and improve.

Identifying Improvement Opportunities Across the Process

End-to-end process mapping is a powerful tool for identifying improvement opportunities. By examining the entire workflow, teams can pinpoint inefficiencies and areas of waste. For instance:

Flowcharts help identify bottlenecks and streamline workflows.

Value stream mapping uncovers waste and highlights opportunities for optimization.

These techniques enable organizations to enhance efficiency and performance. For example, a healthcare provider used value stream mapping to reduce patient wait times. By addressing delays in the intake process, they improved overall service quality.

Tip: Regularly updating end-to-end process maps ensures workflows remain aligned with organizational goals. This practice fosters continuous improvement and adaptability.

Step-by-Step Guide to Creating a Lean Six Sigma Process Map

Step 1: Define the Goals and Scope of the Process Map

Defining the goals and scope is the foundation of any successful Lean Six Sigma process mapping initiative. This step ensures that the process map aligns with organizational objectives and provides a clear direction for improvement efforts. Teams should focus on establishing boundaries and identifying the purpose of the map.

Key guidelines for defining goals and scope include:

Clearly outlining the start and end points of the process to establish its scope.

Involving stakeholders to gather diverse perspectives and foster a sense of ownership.

Validating the process map with stakeholders to ensure it accurately represents the workflow.

Tip: A well-defined scope prevents scope creep and ensures that the mapping effort remains focused on achieving measurable outcomes.

Research highlights the importance of this step. For instance, 81% of studies on process mapping included input from diverse stakeholders, while 91% created maps to represent current practices. Additionally, 78% incorporated details such as delays and safety issues, ensuring a comprehensive understanding of the process.

The primary goal of process mapping is to create a visual representation of workflows. This approach facilitates clear communication among team members, optimizes resource utilization, and clarifies roles and responsibilities.

Step 2: Identify Key Steps and Stakeholders

Identifying the key steps and stakeholders is critical for creating an accurate and actionable process map. This step involves breaking down the workflow into its essential components and determining who is responsible for each task. Engaging stakeholders early in the process ensures alignment and buy-in, which are crucial for successful implementation.

Best practices for this step include:

Engaging stakeholders during goal-setting to gain insights into current challenges and opportunities.

Aligning process mapping goals with key performance indicators (KPIs) to ensure relevance and measurable outcomes.

Conducting workshops or interviews with frontline staff to uncover pain points and gather actionable feedback.

Organizations across industries have achieved significant results by involving stakeholders. For example:

A manufacturing firm reduced production cycle time by 15% by setting clear targets for process mapping.

A healthcare organization improved patient flow by involving medical staff in identifying bottlenecks.

A retail company aligned its goals with KPIs, leading to a 20% reduction in stockouts and improved supply chain efficiency.

Case in Point: A financial services firm adopted BPMN standards to clarify workflows, resulting in a 30% reduction in onboarding time. This example underscores the value of stakeholder engagement in achieving tangible improvements.

Step 3: Gather Data and Input from Team Members

Gathering data and input from team members ensures that the process map reflects the realities of the workflow. This step involves collecting information about current practices, identifying inefficiencies, and exploring opportunities for improvement. Teams should aim to include perspectives from all relevant departments to create a comprehensive map.

Effective strategies for gathering input include:

Conducting cross-functional meetings to discuss process goals and execution methods.

Using tools like the I-P-O (Input-Process-Output) model to document workflows and identify key variables.

Interviewing stakeholders to uncover critical pain points and areas for optimization.

For example, a government agency used the I-P-O model to document existing processes, which led to improved customer service times. Similarly, a recent engagement involved interviewing 38 stakeholders and mapping 18 critical processes. This effort resulted in optimized efficiency and increased margins.

The visual nature of tools like the I-P-O model makes it easier for teams to identify inputs, outputs, and potential error states. By understanding how variations in inputs affect outputs, organizations can implement targeted improvements.

Pro Tip: Comprehensive data collection not only enhances the accuracy of the process map but also fosters a culture of collaboration and continuous improvement.

Step 4: Choose the Right Type of Process Map

Selecting the appropriate process map is crucial for accurately representing workflows and achieving operational improvements. Different types of process maps serve distinct purposes, depending on the complexity of the workflow, the involvement of departments, and the goals of the mapping effort.

Factor | Description |

|---|---|

Complexity of Workflow | Simple tasks are best represented with flowcharts, while complex tasks require BPMN. |

Departmental Involvement | Swimlane diagrams clarify roles when multiple departments are involved. |

Goal | Value stream maps are ideal for waste reduction; SIPOC diagrams provide high-level clarity. |

For example, a team working on a straightforward approval process might use a flowchart to outline the steps. In contrast, a cross-functional team addressing inefficiencies in a supply chain would benefit from a swimlane diagram to clarify roles and responsibilities.

Choosing the right type of process map ensures that the visualization aligns with the specific needs of the project. This alignment helps teams focus on the most critical aspects of the workflow, making the mapping effort more effective and actionable.

Tip: Teams should evaluate their goals and the complexity of their processes before deciding on a mapping tool. This evaluation prevents unnecessary complications and ensures clarity.

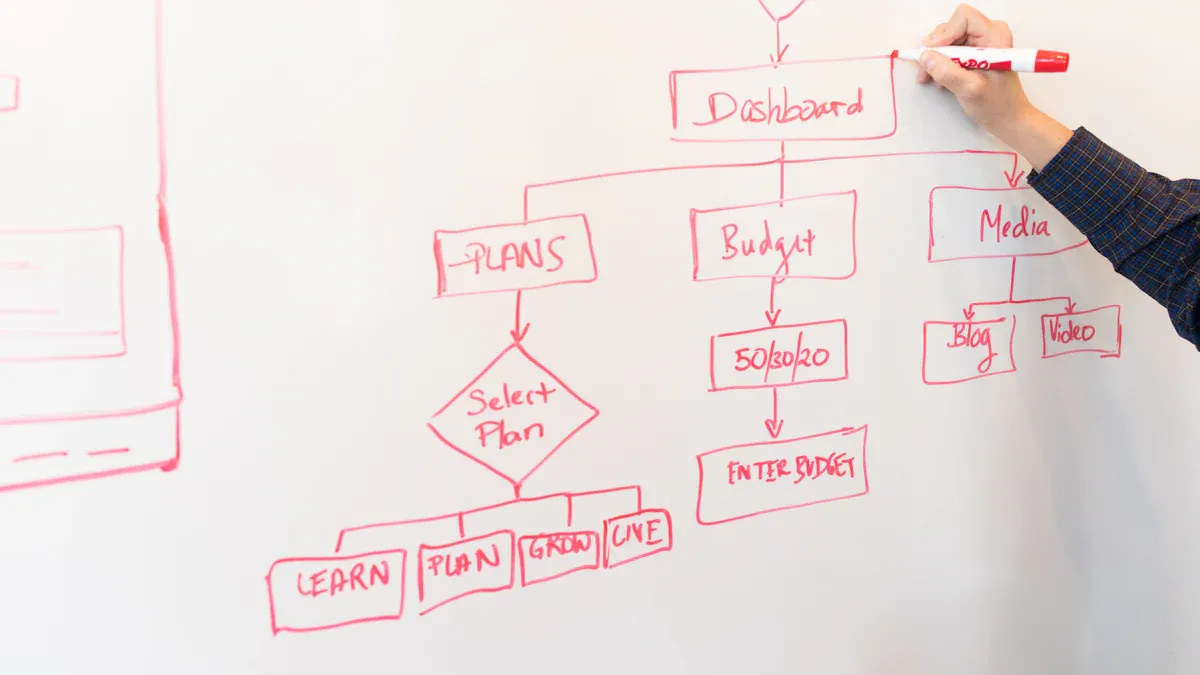

Step 5: Visualize the Process Using Tools or Software

Visualizing the process is a pivotal step in Lean Six Sigma Process Mapping. Teams can use various tools and software to create clear and detailed representations of workflows. These tools help standardize the mapping process and make it easier to share and analyze the results.

Popular software options include Visio, Lucidchart, and Miro. These platforms offer user-friendly interfaces and advanced features like drag-and-drop functionality, real-time collaboration, and customizable templates. For instance, Lucidchart allows teams to create swimlane diagrams with ease, while Miro supports brainstorming sessions for process improvement.

Manual techniques, such as using whiteboards or sticky notes, can also be effective for smaller teams or initial brainstorming sessions. However, digital tools provide advantages like scalability, version control, and the ability to integrate data analytics.

Pro Tip: Teams should choose tools that align with their technical expertise and project requirements. Simpler tools work well for small-scale projects, while more advanced software suits complex workflows.

Step 6: Analyze Pain Points and Inefficiencies

Analyzing pain points and inefficiencies is essential for identifying areas that need improvement. Teams should gather data from stakeholders and use quantitative methods to validate their findings.

Key strategies for analyzing pain points include:

Collecting feedback through interviews, surveys, and focus groups.

Conducting audits to identify inefficiencies in the workflow.

Using metrics to quantify the impact of pain points.

Advanced techniques, such as statistical tests and machine learning models, can provide deeper insights. For example:

Applying Chi-Square or T-Test methods to compare user groups and validate findings.

Simulating alternative workflows to predict the impact of proposed changes.

Risk scoring to prioritize fixes based on the likelihood of user difficulties.

By combining stakeholder input with data-driven analysis, teams can pinpoint the root causes of inefficiencies. This approach ensures that improvement efforts are targeted and effective, leading to measurable gains in operational performance.

Note: Regularly revisiting and updating process maps helps organizations adapt to changing conditions and maintain efficiency over time.

Step 7: Implement and Monitor Improvements

Implementing improvements identified through Lean Six Sigma Process Mapping requires a structured approach. Teams must focus on executing changes effectively and monitoring their impact to ensure sustained success. This step transforms insights from process mapping into actionable results.

Steps for Implementation

Develop an Action Plan

Teams should create a detailed plan outlining the steps required to implement improvements. This plan must include timelines, assigned responsibilities, and measurable objectives. For example, a manufacturing company might schedule equipment upgrades to reduce cycle times.Engage Stakeholders

Involving stakeholders ensures alignment and support during implementation. Teams should communicate the benefits of proposed changes and address any concerns. Collaborative discussions can help prioritize interventions and strengthen systems.Pilot the Changes

Testing improvements on a small scale allows teams to evaluate their effectiveness before full implementation. For instance, a retail chain could pilot a new inventory management system in select stores to assess its impact on stock levels.Train Team Members

Providing training ensures that employees understand their roles in the updated process. Clear instructions and hands-on practice help minimize errors and build confidence.Execute the Plan

Once the pilot phase confirms the changes' effectiveness, teams can roll out the improvements across the organization. Regular updates keep stakeholders informed and engaged.

Monitoring and Measuring Success

Monitoring improvements is essential for ensuring their long-term effectiveness. Teams should track key metrics to evaluate the impact of changes. Common metrics include:

Metric | Description |

|---|---|

Cycle Time | The total time required to complete a process from start to finish. |

Throughput | The rate at which a process generates output over a given period. |

First-Pass Yield | The percentage of units that complete the process correctly on the first attempt. |

Cost per Unit | The total cost associated with producing a single unit of output. |

Customer Satisfaction | A measure of how well processes meet customer expectations. |

These metrics provide valuable insights into the effectiveness of process improvements. For example, a healthcare provider might track patient satisfaction scores to assess the impact of streamlined intake procedures.

Benefits of Continuous Monitoring

Continuous monitoring fosters a culture of improvement. It enables teams to identify new opportunities for optimization and adapt to changing conditions. Organizations that prioritize monitoring often achieve better outcomes, such as:

Outcome | Description |

|---|---|

Stakeholder Convergence | Stakeholders collaborate to understand and improve systems. |

Acknowledgment of Gaps | Teams recognize areas of misunderstanding and address them effectively. |

Prioritization of Interventions | Stakeholders agree on and prioritize actions to strengthen processes. |

Ensuring Sustainability

Sustaining improvements requires ongoing effort. Teams should regularly review process maps and update them to reflect changes. This practice ensures that workflows remain efficient and aligned with organizational goals. Additionally, organizations can use effectiveness metrics, such as error rates and customer satisfaction scores, to measure long-term success.

Tip: Regularly revisiting process maps helps organizations stay agile and responsive to new challenges.

By implementing and monitoring improvements systematically, organizations can maximize the benefits of Lean Six Sigma Process Mapping. This approach not only enhances efficiency but also drives continuous growth and innovation.

Tools for Effective Lean Six Sigma Process Mapping

Software Tools for Process Mapping

Popular Tools (e.g., Visio, Lucidchart, Miro)

Software tools play a vital role in creating accurate and visually appealing process maps. Popular platforms like Visio, Lucidchart, and Miro offer user-friendly interfaces and advanced features that simplify the mapping process. Visio provides a wide range of templates and shapes, making it ideal for creating detailed diagrams. Lucidchart excels in real-time collaboration, allowing teams to work together seamlessly, even from different locations. Miro stands out for its versatility, supporting brainstorming sessions and interactive workshops alongside process mapping.

These tools cater to various industries, from manufacturing to healthcare, by enabling teams to visualize workflows and identify inefficiencies. For example, a manufacturing company can use Visio to map production lines, while a healthcare provider might rely on Lucidchart to streamline patient intake processes. The ability to customize and share maps enhances communication and ensures alignment among stakeholders.

Key Features to Look for in Process Mapping Software

When selecting process mapping software, teams should prioritize features that align with their needs. Key attributes include:

Ease of Use: Intuitive interfaces reduce the learning curve and encourage adoption.

Collaboration Capabilities: Real-time editing and commenting features foster teamwork.

Integration Options: Compatibility with other tools, such as project management software, enhances efficiency.

Customizability: The ability to tailor templates and diagrams ensures the software meets specific requirements.

Data Visualization: Advanced analytics and reporting tools provide insights into process performance.

Research underscores the importance of these features in Lean Six Sigma methodologies. Process mapping tools help visualize current workflows, identify inefficiencies, and plan improvements effectively. This approach ensures that teams can achieve high-quality outcomes while maintaining operational efficiency.

Manual Techniques for Process Mapping

Using Whiteboards, Sticky Notes, and Paper

Manual techniques remain a practical option for teams without access to digital tools. Whiteboards, sticky notes, and paper offer a hands-on approach to process mapping. Teams can brainstorm ideas, arrange steps, and visualize workflows in real time. Sticky notes, in particular, allow for easy adjustments, making them ideal for iterative planning sessions.

For example, a small business might use a whiteboard to map its customer service process. Team members can contribute ideas, rearrange steps, and identify bottlenecks collaboratively. This tactile method fosters engagement and encourages creative problem-solving.

Pros and Cons of Manual vs. Digital Mapping

Both manual and digital mapping methods have unique advantages and limitations.

Aspect | Manual Mapping | Digital Mapping |

|---|---|---|

Cost | Low-cost materials like paper and markers | Higher initial investment for software |

Flexibility | Easy to adjust during brainstorming | Offers advanced customization options |

Collaboration | Best for in-person teamwork | Supports remote and real-time collaboration |

Scalability | Limited to physical space | Easily scalable for complex workflows |

Data Integration | Not applicable | Integrates with analytics and reporting tools |

Manual techniques work well for small teams or initial planning stages. However, digital tools provide scalability and advanced features that are essential for larger organizations. Combining both methods can yield the best results, with manual mapping serving as a foundation for digital refinement.

Tip: Teams should evaluate their resources and project scope before choosing a mapping method. This ensures that the approach aligns with their goals and capabilities.

Common Challenges in Lean Six Sigma Process Mapping and How to Overcome Them

Resistance to Change Among Team Members

Resistance to change often emerges as a significant obstacle during Lean Six Sigma process mapping. Employees may feel apprehensive about altering familiar workflows or adopting new methodologies. This reluctance stems from fear of increased workload, uncertainty about outcomes, or lack of understanding of the benefits.

Organizations can address this challenge by fostering a culture of transparency and inclusion. Leaders should communicate the purpose and advantages of process mapping clearly. Hosting workshops or training sessions can help employees understand how the changes will improve efficiency and reduce frustrations in their daily tasks. For example, a manufacturing firm successfully reduced employee resistance by involving team members in mapping sessions. This approach empowered workers to contribute ideas and eased concerns about the transition.

Tip: Recognizing and addressing employee concerns early in the process builds trust and encourages active participation.

Lack of Stakeholder Engagement and Buy-In

Stakeholder engagement plays a pivotal role in the success of Lean Six Sigma initiatives. Without buy-in from leadership and cross-functional teams, process mapping efforts often face delays or fail to deliver impactful results. Senior leaders may hesitate to allocate resources, while departmental teams might resist collaboration due to competing priorities.

To overcome this challenge, organizations should emphasize the importance of leadership support and cross-functional representation. Pilot projects can demonstrate the tangible benefits of process mapping before scaling efforts. For instance, a retail company used a phased approach to optimize its supply chain. By showcasing early successes, the team secured buy-in from executives and expanded the initiative across all departments.

Challenge | Description |

|---|---|

Essential for successful rollout; requires support from senior leadership for Lean Six Sigma initiatives. | |

Phased Projects | Starting small with pilot projects can demonstrate impact before larger-scale deployment. |

Cross-Functional Teams | Strong representation from various departments is crucial to ensure smooth implementation. |

Note: Engaging stakeholders through regular updates and collaborative discussions ensures alignment and commitment throughout the process.

Overcomplicating the Process Map

Overcomplication often undermines the effectiveness of process mapping. Teams may include excessive details or create overly complex diagrams, making it difficult for stakeholders to interpret and act on the findings. This issue arises when teams focus too much on granular data without considering the overall purpose of the map.

Simplifying the process map is key to overcoming this challenge. Teams should prioritize clarity by focusing on essential steps and avoiding unnecessary details. High-level maps can provide a broad overview, while detailed maps should only be used when analyzing specific inefficiencies. For example, a healthcare provider streamlined its patient intake process by creating a concise swimlane diagram. This simplified visualization helped staff identify bottlenecks and implement changes quickly.

Pro Tip: Use visual tools like flowcharts or SIPOC diagrams to maintain simplicity and ensure the map remains actionable.

By addressing these common challenges, organizations can maximize the benefits of Lean Six Sigma process mapping and drive meaningful improvements in efficiency and collaboration.

Ensuring Accuracy and Relevance of the Map

Accuracy and relevance are critical for the success of any Lean Six Sigma process map. A process map that contains outdated or incorrect information can lead to flawed decisions and wasted resources. Teams must take deliberate steps to ensure the map reflects the current state of the workflow and aligns with organizational goals.

Key Practices for Ensuring Accuracy

Validate Data Sources: Teams should verify the reliability of the data used to create the map. Cross-checking information with multiple stakeholders helps identify discrepancies.

Engage Subject Matter Experts (SMEs): SMEs provide insights into specific processes and ensure the map accurately represents real-world workflows.

Conduct Regular Reviews: Periodic reviews of the map help identify outdated steps or changes in the process. This practice ensures the map remains a true reflection of the workflow.

Use Standardized Symbols and Notations: Consistent use of symbols, such as those in BPMN (Business Process Model and Notation), reduces confusion and enhances clarity.

Tip: Teams can use a checklist to verify the accuracy of each step in the process map. This approach minimizes errors and ensures completeness.

Maintaining Relevance Over Time

Workflows evolve due to changes in technology, market demands, or organizational priorities. To maintain relevance, teams should:

Incorporate Feedback: Regularly gather input from employees who interact with the process. Their feedback highlights areas that need updates.

Monitor Key Metrics: Metrics such as cycle time or defect rates can indicate when a process requires reevaluation.

Schedule Updates: Establish a routine for revisiting and revising the map, such as quarterly or biannually.

A relevant and accurate process map serves as a reliable foundation for decision-making and continuous improvement.

Maintaining Continuous Improvement Post-Mapping

Creating a process map is not the end of the journey. Continuous improvement ensures that workflows remain efficient and adaptable to changing conditions. Organizations must embed a culture of ongoing evaluation and refinement.

Strategies for Sustaining Improvement

Establish Ownership: Assign responsibility for monitoring and updating the process map. This ensures accountability and prevents neglect.

Leverage Metrics: Use performance indicators to track the impact of implemented changes. Metrics like throughput or customer satisfaction provide measurable insights.

Encourage Team Collaboration: Regular team discussions foster a shared commitment to improvement. Employees can share observations and propose enhancements.

Adopt a Feedback Loop: Collect feedback from stakeholders and incorporate it into future updates. This iterative approach keeps the process aligned with organizational needs.

Note: Organizations that prioritize continuous improvement often outperform competitors in efficiency and adaptability.

Tools to Support Continuous Improvement

Digital tools play a vital role in maintaining process maps. Platforms like Lucidchart or Visio allow teams to update maps easily and share them across departments. Automated alerts can notify teams when metrics deviate from acceptable ranges, prompting timely action.

By committing to continuous improvement, organizations can ensure their workflows remain optimized and resilient in a dynamic business environment.

Lean Six Sigma Process Mapping offers organizations a structured way to enhance efficiency and eliminate waste. By visualizing workflows, teams can identify inefficiencies and implement targeted improvements. This approach empowers systems to make informed decisions, optimize processes, and achieve operational excellence. Teams that embrace this methodology foster a culture of continuous improvement, driving long-term success. To learn more about applying these techniques, reach out to us for guidance.

FAQ

What is the main purpose of Lean Six Sigma process mapping?

Lean Six Sigma process mapping aims to visualize workflows, identify inefficiencies, and streamline operations. It helps organizations reduce waste, improve resource allocation, and achieve operational excellence.

How does process mapping improve team collaboration?

Process mapping fosters collaboration by creating a shared understanding of workflows. Teams can identify their roles, responsibilities, and dependencies, which reduces misunderstandings and enhances communication.

What tools are best for creating process maps?

Popular tools include Visio, Lucidchart, and Miro. These platforms offer templates, real-time collaboration, and customization options. For manual mapping, whiteboards and sticky notes work well for brainstorming sessions.

How often should process maps be updated?

Organizations should update process maps regularly, such as quarterly or biannually. Updates ensure workflows reflect current practices and remain aligned with organizational goals.

What is the difference between a SIPOC diagram and a value stream map?

Feature | SIPOC Diagram | Value Stream Map |

|---|---|---|

Focus | High-level overview | Detailed flow of value |

Purpose | Define process boundaries | Identify waste and inefficiencies |

Use Case | Initial project scoping | Lean process improvement |

Can Lean Six Sigma process mapping apply to small businesses?

Yes, small businesses can benefit from process mapping. It helps identify inefficiencies, optimize workflows, and improve customer satisfaction, even with limited resources.

What are common challenges in process mapping?

Common challenges include resistance to change, overcomplicating maps, and lack of stakeholder engagement. Addressing these issues requires clear communication, simplified diagrams, and active involvement from all relevant parties.

How does process mapping support continuous improvement?

Process mapping provides a baseline for measuring progress. Teams can identify inefficiencies, implement changes, and monitor results. Regular updates ensure workflows adapt to evolving business needs.

Tip: Encourage team feedback to keep process maps relevant and actionable.