Understanding Business Process Improvement Methodologies for Modern Organizations

Business process improvement methodologies provide structured ways for organizations to analyze, refine, and enhance their workflows. These approaches help teams reduce waste, improve quality, and increase value for both clients and customers. Many companies report measurable results after adopting these methods, including operational efficiency gains of 20% in the first year and a 40% drop in production defect rates over five years.

Measurable Benefit | Reported Improvement |

|---|---|

Operational efficiency | Increased by approximately 20% within the first year |

Production defect rate | Reduced by about 40% over a five-year period |

Operational costs | Decreased by roughly 30% over five years |

Customer satisfaction | Improved by around 25% over five years |

These results show that following clear optimization steps can lead to lower costs and better experiences for everyone involved.

Key Takeaways

Business process improvement helps organizations reduce waste, cut costs, and improve quality, leading to better customer satisfaction and higher efficiency.

Popular methodologies like Lean, Six Sigma, and Kaizen focus on eliminating waste, reducing defects, and encouraging continuous small improvements.

Strong leadership and clear communication are essential to motivate teams and overcome resistance during process improvement projects.

Involving employees in designing and testing changes increases engagement and leads to practical, lasting improvements.

Using data and key performance indicators (KPIs) helps organizations track progress and make smarter, measurable decisions.

Process mapping and visual tools like Kanban boards make workflows clear, helping teams spot bottlenecks and improve collaboration.

Continuous feedback and iteration keep improvements relevant and help organizations adapt to new challenges over time.

Choosing the right methodology depends on an organization’s goals, culture, resources, and industry context to ensure successful adoption.

Importance of Process Improvement

Efficiency and Waste Reduction

Organizations that focus on process improvement see clear gains in efficiency and waste reduction. They optimize workflows, eliminate unnecessary steps, and use technology to automate routine tasks. For example, a retail chain reduced inventory management costs by 25% within six months by automating inventory tracking and updating ordering protocols. Visualizing workflows helps teams spot bottlenecks and remove inefficiencies. A healthcare facility cut patient discharge time by 45% after removing seven unnecessary steps from its process.

Aspect | Description/Outcome |

|---|---|

Goal | Optimize workflows, reduce waste, enhance quality |

Actions | Automation, staff training, updated protocols, monitoring |

Measurable Benefits | Productivity boost up to 35%, operational cost reduction by 25% |

Process Mapping | Identifies inefficiencies and bottlenecks |

Lean Management | Waste elimination, value maximization |

Technology Integration | IoT, automation, AI for routine tasks |

Employee Development | Training leads to higher profit margins |

Process improvement methodologies like Lean, Six Sigma, and Kaizen target waste by identifying and removing non-value-added activities. Lean eliminates unnecessary tasks and delays, while Six Sigma reduces quality variations. Kaizen encourages employees to suggest improvements, increasing efficiency and commitment. Companies also use continuous improvement software to capture waste opportunities, standardize best practices, and keep teams engaged. This approach leads to lower costs, faster delivery, and better resource use.

Inventory waste shrinks with just-in-time ordering.

Motion waste falls by standardizing workstations.

Waiting waste decreases through balanced workflows.

Overproduction is controlled by producing only what is needed.

Defects are reduced by error-proofing and root cause analysis.

Customer Satisfaction

Process improvement directly boosts customer satisfaction. Streamlined workflows and reduced bottlenecks lead to faster response times and clearer communication. Service representatives become better trained, which improves the customer journey. Organizations that collect and act on customer feedback build trust and loyalty. These efforts create a cycle of ongoing improvement.

Impact Area | Improvement Range | Description |

|---|---|---|

Customer Satisfaction Scores | Significant increases in satisfaction after process optimization | |

Customer Complaints | -45% | Fewer complaints due to improved quality and processes |

Customer Retention Rates | +15% to +25% | Higher retention from better service and experience |

Service Delivery Speed | +45% to +55% | Faster service improves customer perceptions |

Error and Defect Reduction | -50% | Fewer errors contribute to satisfaction |

When organizations invest in employee training and align processes with customer needs, they see higher satisfaction scores, fewer complaints, and improved retention rates.

Innovation and Agility

Process improvement also drives innovation and agility. Companies that empower employees and encourage feedback create a culture where new ideas thrive. For example, Google’s 20% time policy led to products like Gmail and Google News. 3M’s 15% rule produced innovations such as Post-it Notes. Roche uses internal platforms to gather ideas, leading to breakthrough products.

Organizational agility grows when teams have autonomy and leaders support a learning mindset. Decentralized decision-making and multidisciplinary teams help companies adapt quickly to change. Tesla updates its vehicles with new software, Airbnb pivots during crises, and Spotify adapts to user feedback. These examples show that process improvements foster creativity, speed, and resilience, helping organizations stay ahead in a changing world.

Compliance and Risk

Modern organizations face strict regulations and high expectations for risk management. Process improvement methodologies help companies meet these demands by making compliance and risk control part of daily operations. Teams use structured approaches like Lean Six Sigma and the PDCA cycle to build compliance into every project. For example, banks have used these tools to speed up loan approvals while still following all rules, which reduces compliance risks and improves customer satisfaction.

Companies that focus on process improvement see several benefits in compliance and risk management:

Regular compliance reviews help teams spot challenges early and fix them quickly.

Automation tools track compliance tasks, create audit trails, and test for issues.

Training programs and clear documentation make it easier for employees to follow rules.

Agile cycles often include compliance tasks and assign roles to ensure accountability.

Open communication and a culture of responsibility encourage everyone to take compliance seriously.

Continuous monitoring of compliance metrics and KPIs drives ongoing improvement.

Note: The Ponemon Institute found that the cost of non-compliance is much higher than the cost of staying compliant. This fact highlights the financial value of strong compliance processes.

Organizations also see these improvements:

Compliance Benefit | Description |

|---|---|

Faster, simpler compliance steps | |

Fewer audit findings | Reduced risk of penalties and fines |

Better documentation | Clear records for audits and reviews |

Enhanced risk management | Early detection and prevention of problems |

Improved quality metrics | Higher standards and fewer errors |

Continuous process improvement helps companies in regulated industries, such as healthcare and aviation, identify and address risks before they become serious. By formalizing procedures and using data-driven methods, organizations reduce human error and catch issues early. This approach builds stronger, more reliable systems that protect both the company and its customers.

Process improvement also supports long-term sustainability. When teams regularly review and refine their processes, they stay ahead of changing regulations and industry standards. This proactive mindset not only keeps organizations compliant but also strengthens their reputation and trust with stakeholders.

Key Benefits for Organizations

Cost Savings

Process improvement delivers significant cost savings across many areas of an organization. Teams often start by reviewing utility expenses, using energy audits and monitoring tools to cut unnecessary costs. Technology infrastructure also becomes more efficient when companies automate cost alerts and replace outdated systems. Inventory management improves through consumption-based categorization and just-in-time ordering, which reduces waste and storage costs. Customer service departments save money by automating ticket handling and using AI chatbots.

Utility costs drop after energy audits and better equipment use.

IT expenses decrease when teams optimize systems and automate alerts.

Inventory waste shrinks with smarter ordering and storage.

Customer service costs fall with automation and efficient communication.

Industry / Organization Type | Process Improvement Initiative | Significant Cost Savings Reported |

|---|---|---|

Professional Services Firm | Standardizing Work Procedures | Improved productivity, fewer errors, and higher client retention lower labor and correction costs. |

Government Entity | Continuous Improvement Program | Less rework and better resource use reduce overtime and corrective action costs. |

Medical Device Manufacturer | Applying Lean Principles | Better product quality and less scrap lower warranty claims and overhead. |

Food & Beverage Manufacturer | Streamlining Bill of Materials Process | Lower inventory and storage costs, less waste, and improved efficiency reduce labor costs. |

Clothing Retailer | Streamlining Sales and Marketing | Targeted marketing and optimized inventory boost revenue and cut campaign and storage costs. |

Construction Company | Improving Supply Chain Management | Less raw material waste and fewer project delays reduce costs and fines. |

These examples show that process improvement leads to real savings, helping organizations reinvest in growth and innovation.

Employee Engagement

Employee engagement rises when organizations introduce process improvement initiatives. Employees become active participants in brainstorming sessions, workshops, and decision-making. They feel empowered when leaders delegate authority and provide resources. This sense of ownership and motivation grows stronger in a culture that values collaboration and recognition.

A few key actions drive higher engagement:

Leaders explain the benefits of continuous improvement to everyone.

Teams involve employees in generating ideas and making decisions.

Organizations offer training and ongoing support to build skills.

Managers recognize and reward employee contributions.

Cross-functional teams encourage open communication and teamwork.

Regular feedback helps teams refine processes and stay motivated.

Process mapping increases visibility and understanding of each role, which reduces frustration and blame. Automation of repetitive tasks allows employees to focus on creative and meaningful work. According to a Forbes Insight survey, automating mundane tasks improves employee satisfaction by 92%. Streamlined onboarding and training also help new hires feel connected and engaged from day one. These changes lead to higher morale, better retention, and a stronger sense of purpose.

Data-Driven Decisions

Data-driven decisions play a vital role in successful process improvement. Teams use operational data to identify inefficiencies, root causes, and opportunities for change. Tracking key performance indicators (KPIs) helps organizations validate solutions and measure progress. Six Sigma’s DMAIC framework, for example, relies on data at every stage to solve problems and improve quality.

Aspect | Evidence and Impact |

|---|---|

Systematic Analysis | Teams find inefficiencies and root causes using operational data. |

Performance Tracking | KPIs help validate solutions and track progress. |

Productivity Improvement | Focusing on high-impact changes increases productivity by 20-30%. |

Quality Enhancement | Statistical process control reduces defects by up to 40%. |

Cost Optimization | Data-driven choices cut operational costs by 15-25%. |

Risk Management | Predictive analytics lower downtime and safety incidents by up to 35%. |

Advanced Tools | Statistical software and data visualization turn raw data into insights. |

Industry Applications | Walmart improved inventory turnover by 25%; Amazon cut order processing time by 50%. |

Continuous Improvement | Ongoing data review ensures processes keep improving. |

By relying on data, organizations make smarter decisions, reduce risks, and achieve better results. Data-driven approaches ensure that improvements are measurable, repeatable, and sustainable.

Scalability

Scalability stands as a crucial benefit for organizations that adopt business process improvement methodologies. As companies grow, they often face new challenges. These challenges include increased complexity, more customers, and higher expectations for quality and speed. Without scalable processes, organizations may struggle to keep up with demand or maintain consistent results.

Process improvement methodologies help organizations prepare for growth by creating systems that can expand smoothly. Teams start by identifying pain points and inefficiencies that could slow down progress. For example, a company might notice that order processing takes too long when sales increase. By targeting these bottlenecks, teams can streamline workflows and remove obstacles before they become major problems.

Organizations also define clear objectives for scalable processes. Leaders envision what the company will need as it grows. They set goals that align with long-term strategies. This approach ensures that every improvement supports future expansion, not just current needs.

Training plays a key role in scalability. Teams involve key stakeholders in the process and provide thorough training on new procedures. When everyone understands the changes, adoption becomes easier. Employees feel confident using new systems, which leads to better results and fewer mistakes.

Monitoring progress helps organizations stay on track. Teams use key performance indicators (KPIs) and dashboards to track how well new processes work. These tools provide real-time feedback and help leaders spot issues quickly. Regular monitoring keeps everyone accountable and focused on continuous improvement.

Continuous feedback and refinement ensure that processes remain valuable as the organization grows. Teams collect input from employees and customers. They use this feedback to make adjustments and keep processes efficient. This ongoing effort helps organizations adapt to changing needs and maintain high performance.

Tip: Standardizing processes early makes it easier to scale later. Consistent procedures reduce confusion and help new employees learn quickly.

The following table highlights how process improvement supports scalability:

Step | Benefit for Scalability |

|---|---|

Identify pain points | Removes bottlenecks before growth occurs |

Set clear objectives | Aligns improvements with future needs |

Train teams | Ensures smooth adoption of new processes |

Monitor with KPIs | Tracks progress and maintains focus |

Collect and refine feedback | Keeps processes relevant and efficient |

Organizations that focus on scalability can handle larger workloads, serve more customers, and enter new markets with confidence. Process improvement methodologies give them the structure and flexibility needed to grow without losing quality or efficiency. As a result, companies remain competitive and resilient, even as they expand.

Business Process Improvement Methodologies

Lean

Lean stands as one of the most popular business process improvement methodologies. It focuses on maximizing value for customers by eliminating waste and improving process flow. Lean encourages teams to look for steps that do not add value, such as waiting, overproduction, or unnecessary movement. By removing these wastes, organizations can deliver products and services faster and at a lower cost.

The core principles of Lean include waste reduction, process flow improvement, continuous improvement (Kaizen), customer satisfaction focus, and the use of practical tools. Teams often use value stream mapping to visualize each step and identify areas for improvement. The 5S system helps organize workspaces, while Kanban boards manage workflow and resources. Poka-Yoke methods prevent errors before they happen.

Core Principles | Description | Measurable Outcomes |

|---|---|---|

Waste Reduction | Systematic elimination of non-value-adding activities to improve efficiency. | Reduced waste and variability, cost savings. |

Process Flow Improvement | Enhancing the smoothness and speed of processes by removing bottlenecks and interruptions. | Increased process reliability and predictability. |

Continuous Improvement (Kaizen) | Ongoing incremental improvements involving all employees to sustain and enhance processes. | Stronger organizational culture, sustained performance gains. |

Customer Satisfaction Focus | Aligning processes to exceed customer expectations and deliver high-quality products/services. | Improved customer satisfaction, loyalty, and reduced product returns. |

DMAIC Cycle | A data-driven problem-solving framework to identify, analyze, and control process improvements. | Enhanced quality and consistency, data-based decision making, and sustained improvements. |

Tools (Value Stream Mapping, 5S, Kanban, Poka-Yoke) | Practical methods to identify waste, organize workspaces, manage workflow, and prevent errors. | Measurable improvements in efficiency, error reduction, and workflow management. |

A manufacturing company used Lean to reduce waiting time and inventory waste. By mapping the value stream and organizing workstations, the team cut production time by 30%. Employees held regular Kaizen events to suggest small changes, which led to ongoing improvements and higher morale.

Tip: Lean works best when everyone participates in finding and fixing problems. Small changes add up to big results over time.

Six Sigma

Six Sigma is another leading approach among business process improvement methodologies. It aims to reduce defects and process variation using a data-driven method called DMAIC: Define, Measure, Analyze, Improve, and Control. Six Sigma relies on statistical tools to find the root causes of problems and to measure progress.

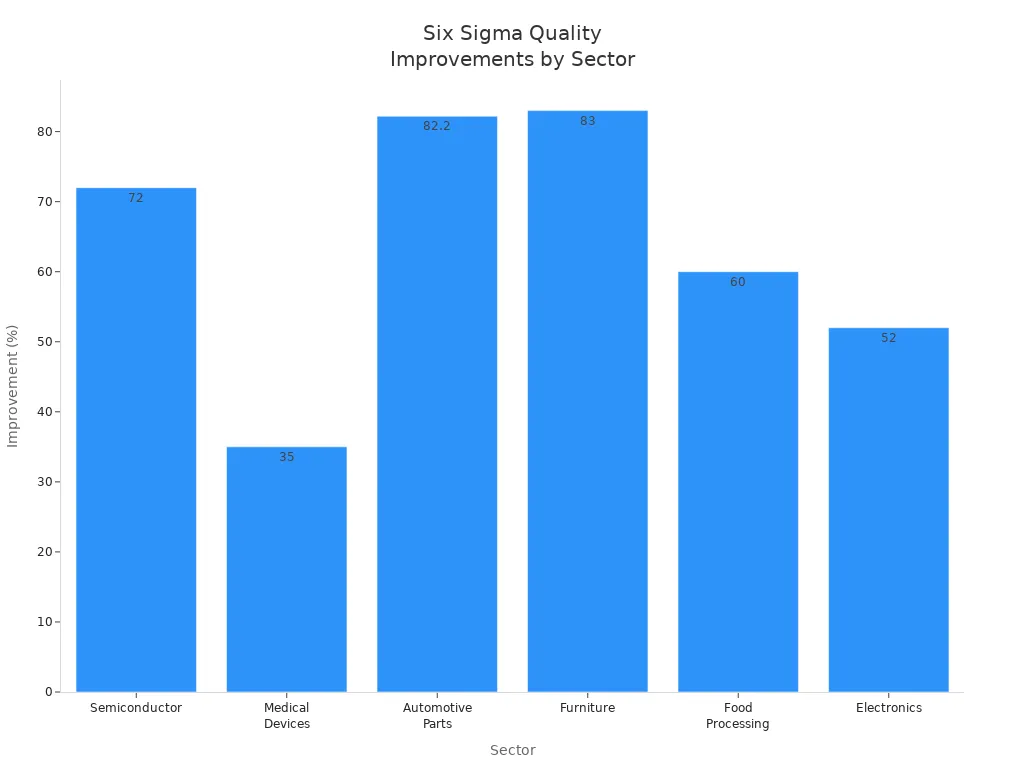

Organizations in manufacturing, healthcare, and education have used Six Sigma to achieve impressive results. For example, a semiconductor company reduced wafer etching defects by 72%, saving millions in scrap costs. A medical device manufacturer increased assembly throughput by 35% without hiring more staff. In the automotive sector, a parts supplier cut setup time on a stamping press from 45 minutes to just 8 minutes, adding over 100 hours of production each year.

Sector | Application Area | Quantifiable Improvement |

|---|---|---|

Semiconductor | Wafer etching defect rate | Reduced defects by 72%, saving millions in scrap |

Medical Devices | Assembly throughput | Increased throughput by 35% without extra staff |

Automotive Parts | Setup time on stamping press | Reduced setup time from 45 to 8 minutes, adding 100+ hours production annually |

Furniture | Finish quality | Reduced customer complaints by 83% through root cause analysis |

Food Processing | Transportation waste | Cut material movement by 60%, improved throughput by 15% |

Electronics | Inventory optimization | Reduced work-in-process inventory by 52%, freeing cash and space |

Six Sigma also helps schools and hospitals. For instance, a school district used Six Sigma to improve classroom air quality and standardize textbooks. These changes led to better student health and more reliable test results. Six Sigma projects often result in higher productivity, fewer errors, and lower costs.

Lean Six Sigma

Lean Six Sigma combines the strengths of Lean and Six Sigma. This hybrid approach targets both waste and process variation. Teams use Lean tools to streamline workflows and Six Sigma methods to reduce defects. The result is a faster, more reliable process with fewer mistakes.

A manufacturing company applied Lean Six Sigma to its assembly line. Before the project, the defect rate stood at 15%. After six months, the defect rate dropped to 4.5%. The team used root cause analysis, standardized procedures, and better equipment maintenance. These changes led to lower costs and higher customer satisfaction.

Metric | Before Lean Six Sigma | After Lean Six Sigma |

|---|---|---|

Defect Rate | 15% | 4.5% |

Cost of Waste and Rework | High | Reduced |

Customer Satisfaction | Low | Improved |

Lean Six Sigma projects focus on controlling variation and eliminating waste. Teams use tools like Statistical Process Control, mistake-proofing, and the 5 Whys. By shifting from reactive problem-solving to proactive root cause elimination, organizations achieve lasting improvements. Lean Six Sigma also builds a culture of continuous improvement and trains employees to sustain gains.

Note: Lean Six Sigma works well in both manufacturing and service industries. It helps organizations deliver consistent quality and adapt quickly to change.

Total Quality Management

Total Quality Management (TQM) stands as a comprehensive approach that focuses on long-term success through customer satisfaction and continuous improvement. Organizations that adopt TQM involve every employee in the process of improving products, services, and culture. Leaders set the vision, and teams work together to meet quality goals.

TQM relies on several core principles:

Leadership commitment to quality at every level.

Employee involvement and teamwork.

Focus on customer needs and satisfaction.

Process management and prevention of errors.

Continuous improvement in all areas.

Empirical studies show that TQM helps organizations achieve lasting performance. Companies that use TQM build a culture where everyone looks for ways to improve. This approach leads to higher customer loyalty and a strong competitive edge. Experts like Deming, Juran, and Crosby highlight that TQM reduces waste and lowers the cost of fixing mistakes. Many international standards, such as ISO 9001:2015, include TQM principles to help organizations reach excellence.

Organizations see these benefits when they implement TQM:

Continuous improvement and innovation become part of daily work.

Customer satisfaction increases, leading to repeat business.

Waste and rework costs drop, saving money.

Teams work better together, sharing knowledge and solving problems.

Safety and health performance improve, supporting long-term goals.

TQM shapes a company’s culture by making quality everyone’s responsibility. This mindset supports sustainable growth and helps organizations adapt to change.

Kaizen

Kaizen means “change for the better” in Japanese. It is a philosophy that encourages small, daily improvements involving everyone in the organization. Kaizen focuses on making processes more efficient, reducing waste, and improving quality step by step.

Key areas where Kaizen makes a difference include:

Overproduction: Teams use just-in-time methods to avoid making too much.

Inventory: Kanban systems help materials flow only when needed.

Transportation: Reducing unnecessary movement saves time and resources.

Overprocessing: Simplifying steps ensures focus on value-added activities.

Motion: Optimized workstations cut down on wasted movement.

Waiting: Better communication and maintenance reduce downtime.

Defects: Ongoing quality checks prevent faulty products.

Many industries have seen success with Kaizen. The table below shows practical examples:

Industry | Example & Outcome |

|---|---|

Manufacturing | Canon’s Visual Management made production data visible, allowing quick fixes and fewer defects. |

Healthcare | Virginia Mason Medical Center reduced patient wait times and errors, improving safety and satisfaction. |

Office Workflows | Ford streamlined document handling and automated tasks, boosting productivity. |

Retail | Tesco empowered staff to suggest changes, optimized store layouts, and improved checkout speed and sales. |

Software Development | Atlassian’s Innovation Weeks led to new features and better workflows. |

Construction | Boldt Construction’s OneBoldt approach improved project speed, safety, and cost efficiency. |

Kaizen works best when everyone participates. Small changes add up to big results over time.

PDCA Cycle

The PDCA Cycle stands for Plan-Do-Check-Act. It is a simple, repeatable method that helps organizations improve processes and solve problems. Teams use PDCA to plan changes, test them, check results, and act on what they learn.

Companies apply the PDCA Cycle in many ways:

Business process optimization: Teams plan, try, and refine processes to boost performance.

Workflow documentation: Clear steps help teams revisit and improve tasks regularly.

Data-driven decisions: Teams collect data, test ideas, and adjust plans based on results.

Change implementation: Small-scale pilots reveal issues before full rollout.

System migration: PDCA guides smooth transitions to new tools or workflows.

Product development: Teams test prototypes, gather feedback, and improve designs.

Supplier management: Teams set standards, check quality, and fix problems quickly.

Lean initiatives: PDCA supports tools like 5S for organized, efficient workplaces.

Training and development: Teams plan sessions, review outcomes, and adjust content.

Maintenance management: Teams schedule, perform, and improve equipment care.

Application Area | Description |

|---|---|

Teams identify problems, plan fixes, test on a small scale, and refine operations. | |

Quality Control | Teams set standards, apply new measures, analyze defects, and adjust processes to improve quality. |

Product Development | Teams create prototypes, test with users, gather feedback, and refine products. |

Supplier Management | Teams plan criteria, check material quality, and act on issues. |

Lean Manufacturing Initiatives | Teams use PDCA to organize workspaces and reduce waste. |

Training and Development | Teams plan objectives, conduct sessions, and adjust based on performance. |

Maintenance Management | Teams plan schedules, perform tasks, and adjust procedures to reduce downtime. |

Nike used the PDCA Cycle to improve working conditions in its factories. The company empowered employees, introduced incentives, and tracked performance. This approach led to better results and higher satisfaction.

The PDCA Cycle helps organizations make steady progress. By repeating the cycle, teams keep improving and adapting to new challenges.

Business Process Reengineering

Business Process Reengineering (BPR) focuses on redesigning core business processes to achieve dramatic improvements in productivity, efficiency, and quality. Organizations use BPR to rethink how work gets done, often starting from scratch. Teams analyze existing workflows, remove unnecessary steps, and introduce new technologies that align with business goals.

Many large companies have seen major benefits from BPR projects. For example, Ford Motor Company and major telecom firms reorganized their teams, which led to significant cost savings and shorter cycle times. These organizations accelerated information flow, reduced errors, and improved the quality of service calls. Teams gained clear ownership of processes, allowing for instant feedback and better performance evaluation.

Key outcomes of BPR projects include:

Cost reduction by eliminating unnecessary steps and optimizing resources.

Increased efficiency through simplified workflows and removal of bottlenecks.

Technology optimization by integrating new tools that support business strategy.

Fewer errors, resulting in higher quality goods and services.

Enhanced flexibility and scalability to adapt quickly to market changes.

Improved customer satisfaction by focusing on customer needs.

Competitive advantage through better quality, lower costs, and improved service.

Greater employee satisfaction by removing tedious tasks and boosting morale.

Improved decision-making with insights from redesigned processes.

A practical example comes from Ford, which reengineered its accounts payable process. By automating tasks and removing redundant approvals, Ford reduced its workforce in that department by 75% and improved accuracy. This change also allowed the company to respond faster to supplier needs.

Note: Successful BPR requires strong leadership, clear communication, and support for employees as they adapt to new ways of working.

Agile and Scrum

Agile and Scrum are popular Business Process Improvement Methodologies that help organizations respond quickly to change. Agile promotes iterative development and continuous delivery. Teams break projects into small, manageable parts called sprints. Scrum provides a structured framework with defined roles, such as Scrum Master and Product Owner, and regular ceremonies like Sprint Planning and Daily Standups.

These methods offer several advantages:

Agile encourages teams to deliver value in short cycles, allowing for rapid adjustments.

Scrum uses fixed-duration sprints and daily meetings to monitor progress and resolve issues quickly.

Both methods foster collaboration, transparency, and customer involvement, leading to faster time-to-market and higher product quality.

Agile and Scrum break work into increments, making it easier to refine processes and adapt to new requirements.

Scrum Masters help remove obstacles, keeping teams focused and productive.

A software company used Agile and Scrum to launch a new app. The team held daily standups, reviewed progress every two weeks, and adjusted priorities based on customer feedback. This approach helped the company release updates faster and improve user satisfaction.

Tip: Agile and Scrum work best when teams communicate openly and focus on continuous improvement.

Just-In-Time

Just-In-Time (JIT) is a methodology that aims to produce only what is needed, when it is needed, and in the amount needed. JIT helps organizations reduce waste, lower costs, and improve efficiency by minimizing inventory and streamlining production.

Waste reduction by avoiding excess inventory and defective products.

Improved efficiency through lower procurement, management, and storage costs.

Increased productivity with faster manufacturing and easier product changes.

Optimized production by eliminating bottlenecks and shortening cycles.

Cost reduction by minimizing working capital and labor expenses.

Quality improvement by focusing on high-quality products and reducing defects.

Better cash flow due to less money tied up in inventory.

Enhanced supplier relationships for timely deliveries.

A car manufacturer implemented JIT by working closely with suppliers to deliver parts only as needed. This change reduced storage costs, improved cash flow, and allowed the company to respond quickly to changes in customer demand.

JIT requires strong supplier partnerships and reliable processes to ensure materials arrive exactly when needed.

Kanban

Kanban is a visual management tool that helps teams organize and track work as it moves through different stages. Teams use Kanban boards, which display tasks as cards and workflow stages as columns. This setup gives everyone a clear, real-time view of what is happening in the process.

Kanban boards show each step of the workflow, making it easy to see where tasks are and what needs attention.

Teams can spot bottlenecks quickly. If too many cards pile up in one column, it signals a problem that needs fixing.

Work-in-progress (WIP) limits prevent teams from taking on too many tasks at once. This focus improves task completion rates and reduces stress.

Visual workload management helps leaders see if some team members have too much work while others have too little. They can then redistribute tasks to keep everyone balanced.

Kanban boards use metrics like cycle time and lead time to measure how long tasks take. Teams use this data to find ways to work faster and more efficiently.

Kanban encourages transparency and accountability. Everyone knows who is working on what, which improves communication and teamwork.

Real-world examples show Kanban’s impact. Microsoft Azure DevOps uses Kanban boards to manage software development, leading to better workflow visibility and faster delivery. Toyota, the originator of Kanban, improved operational efficiency and reduced waste by making work visible and limiting WIP.

Tip: Kanban works well for both small teams and large organizations. It supports continuous improvement by making problems easy to see and fix.

Root Cause Analysis

Root Cause Analysis (RCA) is a structured approach to finding the underlying reasons for problems. Instead of just fixing symptoms, RCA helps teams solve the real issues so they do not come back.

RCA builds strong problem-solving skills. Employees learn to analyze complex situations and think critically.

By addressing root causes, organizations prevent the same problems from happening again. This leads to long-term solutions, not just quick fixes.

RCA creates a proactive culture. Teams focus on preventing issues instead of reacting to them after they occur.

Operational efficiency improves because RCA helps identify and remove inefficiencies and waste.

Customer satisfaction rises when teams resolve the true causes of complaints and anticipate future problems.

RCA supports better decision-making. Teams target core business problems, which saves time and resources.

Involving cross-functional teams brings different perspectives, leading to higher quality solutions.

A blameless culture encourages honesty and transparency, making it easier to find and fix the real issues.

For example, a manufacturing company used RCA to investigate frequent machine breakdowns. The team discovered that poor maintenance schedules, not operator error, caused the failures. By updating the maintenance plan, the company reduced downtime and saved money.

Note: Leadership support and regular training help make RCA a lasting part of a company’s problem-solving toolkit.

RAPID

RAPID is a decision-making framework that clarifies who does what in the decision process. The name stands for Recommend, Agree, Perform, Input, and Decide. Each role has a clear responsibility, which helps teams make decisions faster and with greater accountability.

RAPID defines roles for gathering information, giving input, approving, and taking action. This clarity ensures no task is missed.

The framework boosts engagement by involving the right people at the right time. Team members feel valued and contribute to better decisions.

Clear decision roles eliminate confusion and finger-pointing. Everyone knows who is responsible for each part of the process.

RAPID speeds up decision-making. Teams move quickly from decision to action, which is important in fast-changing industries.

The framework encourages documentation and transparency. Teams keep records of decisions, which helps with learning and future planning.

RAPID supports collaboration and innovation by bringing in diverse perspectives when needed.

Creating a Delegation of Authority (DOA) matrix with RAPID clarifies who has the power to make which decisions, streamlining operations.

For instance, a technology company used RAPID to launch a new product line. By assigning clear roles, the team avoided delays and brought the product to market ahead of competitors. This approach gave the company a strong advantage.

Tip: RAPID works best when organizations keep the decision group small and avoid making the process too complex.

Global 8-D

The Global 8-D (Eight Disciplines) methodology offers a structured approach for solving complex problems. Teams use this method to identify, correct, and prevent recurring issues. The process consists of eight clear steps, each designed to guide teams from problem identification to long-term prevention.

The 8-D process includes:

Team Formation: Assemble a cross-functional group with the right skills.

Problem Description: Define the problem in detail, using data and facts.

Interim Containment: Implement temporary actions to isolate the issue and protect customers.

Root Cause Analysis: Investigate and identify the underlying cause of the problem.

Permanent Corrective Actions: Develop and implement solutions that address the root cause.

Validate Solutions: Test corrective actions to ensure they resolve the issue.

Prevent Recurrence: Update processes, procedures, or training to stop the problem from returning.

Recognize the Team: Celebrate the team's efforts and document lessons learned.

The 8-D methodology originated in the automotive industry. Ford Motor Company developed it in the 1980s to address quality issues in vehicle manufacturing. Since then, organizations in manufacturing, assembly, and service industries have adopted it worldwide. The method has also proven effective in healthcare and technology sectors. These industries value 8-D for its structured process and focus on preventing recurring problems.

For example, an aerospace company used 8-D to address a recurring defect in aircraft components. The team followed each discipline, identified a supplier issue, and implemented new inspection steps. As a result, defect rates dropped, and customer satisfaction improved.

Teams that use Global 8-D benefit from a clear roadmap for problem-solving. This approach not only fixes current issues but also strengthens processes for the future.

Theory of Constraints

The Theory of Constraints (TOC) helps organizations find and address bottlenecks that limit performance. This methodology focuses on the single most critical factor that restricts throughput in a process. By improving this constraint, teams can boost overall productivity and efficiency.

TOC uses several techniques to identify bottlenecks:

Value stream mapping highlights where delays or inventory build up.

Teams collect data on throughput and cycle times to spot slow points.

Observing backlogs and interviewing staff helps locate hidden constraints.

Once teams identify the constraint, they follow the Five Focusing Steps, also known as POOGI (Process of Ongoing Improvement):

Identify the Constraint: Analyze the workflow to find where progress slows or inventory accumulates.

Exploit the Constraint: Maximize output from the bottleneck without extra investment. Teams may reduce setup times or ensure the resource runs at full capacity.

Subordinate Other Processes: Align all other activities to support the constraint. This prevents overproduction and keeps the workflow balanced.

Elevate the Constraint: If the bottleneck remains, invest in more capacity or redesign the process.

Repeat the Process: After resolving one constraint, teams look for the next limiting factor and continue improving.

In lean manufacturing, traditional signs like large work-in-process may not appear. TOC uses flow constraint analysis and effective utilization analysis to detect bottlenecks, even in moving assembly lines. These methods compare actual throughput to ideal capacity and use minimal data when needed.

A practical example comes from a packaging plant. The team noticed delays at the labeling station. By applying TOC, they adjusted schedules and improved machine maintenance. The bottleneck cleared, and the plant increased output without extra equipment.

The Theory of Constraints gives organizations a focused way to improve. By always targeting the weakest link, teams achieve continuous gains in speed and quality.

Selecting the Right Methodology

Assessing Needs

Organizations must start by understanding their specific needs before choosing a process improvement methodology. No single approach fits every situation. Leaders should look at the nature of their processes. Some organizations want to improve existing workflows, while others need to design new ones. The focus areas also matter. Some teams want to boost efficiency, others aim to reduce waste, and some need to eliminate defects or improve customer satisfaction.

For example, Six Sigma works well for organizations that rely on data and statistics to reduce variation. Lean fits companies that want to remove waste and speed up processes. Total Quality Management helps those who want to focus on customer-driven quality and ongoing improvement. Smaller organizations may benefit from Kaizen, which encourages small, daily changes. Teams facing recurring problems may use root cause analysis, such as the 5 Whys.

Leaders should also consider their capacity for data-driven approaches. Some methods require strong data collection and analysis skills. Others focus more on teamwork and culture. The best choice depends on the organization's goals, workforce needs, and unique challenges. Following trends or copying other companies does not guarantee success. Each organization must find a method that matches its own context.

Tip: Clear communication and early engagement help teams accept and adopt new methods. Training and ownership make improvements last.

Process Maturity

Process maturity describes how well an organization understands and manages its workflows. Organizations with mature processes have clear documentation, consistent results, and strong measurement systems. These organizations can use advanced methods like Six Sigma or Lean Six Sigma, which rely on data and detailed analysis.

Organizations with less mature processes may not have clear steps or reliable data. In these cases, simpler methods like Kaizen or the PDCA Cycle work better. These approaches help teams build discipline and improve step by step. As process maturity grows, organizations can move to more complex methods.

A simple table can help teams match process maturity with suitable methodologies:

Process Maturity Level | Suitable Methodologies |

|---|---|

Low | Kaizen, PDCA Cycle, 5 Whys |

Medium | Lean, TQM, Root Cause Analysis |

High | Six Sigma, Lean Six Sigma, BPR |

Industry Context

Industry context shapes which methodology will work best. Each industry faces different challenges and regulations. Manufacturing companies often use Lean or Six Sigma to reduce waste and defects. Healthcare organizations may focus on patient safety and compliance, making TQM or PDCA a good fit. Service industries might choose Agile or Kanban to improve flexibility and speed.

Some industries need strict quality control, while others value innovation and rapid change. For example, technology firms may use Agile to adapt quickly. Food and beverage companies may rely on Just-In-Time to manage inventory and freshness. Leaders should consider industry standards, customer expectations, and regulatory requirements when selecting a methodology.

Organizations should also think about their long-term goals and culture. A method that fits the industry and supports the company’s vision will deliver better results. Integrating change management helps teams overcome resistance and sustain improvements.

Culture and Resources

Organizational culture and available resources play a major role in selecting the right business process improvement methodology. Every company has its own values, beliefs, and ways of working. These factors shape how teams respond to change and improvement efforts.

A strong culture of collaboration and openness supports methods like Kaizen or Agile. In these environments, employees feel comfortable sharing ideas and suggesting changes. Leaders encourage feedback and reward innovation. Teams work together to solve problems and make improvements. Companies with this type of culture often succeed with continuous improvement approaches.

Some organizations have a more traditional or hierarchical culture. In these settings, decisions come from the top, and employees may hesitate to speak up. Methods like Six Sigma or Business Process Reengineering (BPR) can work well here. These approaches rely on clear roles, structured processes, and strong leadership direction.

Resources also affect which methodology fits best. Teams need time, money, and skills to carry out improvement projects. For example, Six Sigma requires training in data analysis and statistical tools. Lean projects may need investment in new equipment or technology. Smaller companies with limited budgets might choose Kaizen or PDCA, which focus on small, low-cost changes.

The table below shows how culture and resources influence methodology selection:

Culture Type | Resource Level | Best-Fit Methodologies |

|---|---|---|

Collaborative | High | Lean, Agile, Kaizen, Six Sigma |

Collaborative | Low | Kaizen, PDCA, Kanban |

Hierarchical | High | Six Sigma, BPR, TQM |

Hierarchical | Low | PDCA, Root Cause Analysis |

Tip: Leaders should assess their company’s culture and resources before choosing a methodology. They can start with a simple survey or team discussion to understand readiness for change.

Companies that invest in training and communication see better results. Employees need to understand the reasons for change and how new methods will help them. Regular workshops, clear instructions, and visible support from leaders build trust and confidence.

A positive culture and enough resources set the stage for successful process improvement. When teams feel supported and have the tools they need, they can achieve lasting results. Organizations that match their methodology to their culture and resources move forward faster and with fewer obstacles.

Implementation Steps

Leadership Support

Leadership support forms the foundation of any successful process improvement initiative. Leaders set the vision and provide the resources teams need. They communicate the importance of improvement and show commitment through their actions. When leaders actively participate, employees feel motivated and understand the value of change.

Strong leadership also helps overcome common challenges. For example, resistance to change often appears when employees feel uncertain. Leaders can address this by sharing clear goals, listening to concerns, and celebrating early wins. They should encourage open communication and provide regular updates. This approach builds trust and keeps everyone aligned.

Tip: Leaders who recognize and reward progress inspire teams to stay engaged throughout the process.

Team Formation

Building the right team is a critical step in process improvement. Teams should include members from different departments and levels. This diversity brings a range of skills and perspectives. Each member should understand their role and how they contribute to the project’s success.

A well-formed team communicates openly and works together to solve problems. They share ideas, identify obstacles, and support each other. Assigning clear responsibilities prevents confusion and ensures accountability. Teams that meet regularly can track progress and adjust plans as needed.

Common challenges during team formation include unclear roles and lack of alignment. Organizations can address these by holding kickoff meetings, setting expectations, and providing training. Involving employees early helps reduce resistance to change and builds a sense of ownership.

Team Formation Step | Benefit |

|---|---|

Diverse membership | Broader skill set |

Clear roles | Less confusion |

Regular meetings | Better communication |

Early involvement | Higher engagement |

Process Mapping

Process mapping gives teams a visual understanding of how work flows within the organization. By creating diagrams or flowcharts, teams can see each step in a process. This makes it easier to spot inefficiencies, bottlenecks, and areas for improvement.

Process mapping also helps align team members and stakeholders. Everyone gains a shared understanding of the current state. This clarity supports better decision-making and goal setting. Teams can use tools like value stream mapping or swimlane diagrams to organize information.

Several challenges can arise during process mapping. Teams may struggle with incomplete information or lack of agreement on steps. To overcome these, organizations should gather input from all involved, encourage open discussion, and verify details with data. Regular reviews keep maps accurate as processes evolve.

Process mapping supports clear communication.

It helps measure success by setting baselines and identifying key performance indicators.

Teams use process maps to guide improvements and monitor progress.

Note: A structured approach like process mapping reduces misunderstandings and sets the stage for effective change.

Setting Objectives

Setting clear objectives gives process improvement projects direction and purpose. Teams need to know what they want to achieve before they start making changes. Objectives should be specific, measurable, achievable, relevant, and time-bound (SMART). This approach helps everyone stay focused and track progress.

Teams often begin by asking key questions:

What problem does the organization want to solve?

How will success look and feel?

Which metrics will show improvement?

A simple table can help teams define objectives:

Objective Example | Metric | Target Value | Deadline |

|---|---|---|---|

Reduce order processing time | Average hours per order | 20% decrease | 6 months |

Improve customer satisfaction | Survey score | +10 points | 1 year |

Lower defect rate | Defects per 1,000 units | 50% reduction | 9 months |

Teams should share objectives with all stakeholders. This transparency builds trust and keeps everyone aligned. Leaders can use visual dashboards to display progress. Regular check-ins help teams adjust goals if needed.

Tip: Teams should avoid setting too many objectives at once. Focusing on a few key goals increases the chance of success.

Designing Improvements

Designing improvements means creating solutions that address the root causes of problems. Teams use data from process mapping and objective setting to brainstorm ideas. They should involve people who work in the process every day. These employees often know where the biggest issues hide.

Teams can use these steps to design improvements:

List possible solutions for each problem area.

Evaluate each idea for impact, cost, and ease of implementation.

Select the best options and create a simple action plan.

Test changes on a small scale before rolling them out.

A block quote can highlight a best practice:

Involving frontline employees in solution design leads to practical and lasting improvements.

Teams should document each change. This record helps track what works and what does not. Leaders should encourage creativity but keep solutions realistic. Teams can use pilot programs or simulations to test ideas safely.

Training and Change

Training prepares employees for new processes and tools. Change can feel difficult, so clear communication and support matter. Teams should create training materials that match the needs of different roles. Hands-on workshops, step-by-step guides, and short videos work well for most learners.

A checklist for effective training:

Explain why the change is happening.

Show how new processes work.

Provide practice opportunities.

Offer support and answer questions.

Gather feedback and make improvements.

Leaders should recognize that people adapt at different speeds. Some employees may need extra help. Regular follow-up sessions keep skills sharp and address any confusion.

Note: Ongoing training and open communication help teams accept change and maintain improvements over time.

Monitoring Progress

Monitoring progress ensures that process improvement efforts deliver real results. Organizations need to track changes, measure outcomes, and adjust strategies as needed. This step helps teams see what works and where they need to improve.

Teams start by selecting key performance indicators (KPIs). These metrics show if the new processes meet the set objectives. Common KPIs include cycle time, error rates, customer satisfaction scores, and cost savings. Teams should choose KPIs that match their goals and industry.

A simple table can help teams organize their KPIs:

KPI Example | What It Measures | Why It Matters |

|---|---|---|

Cycle Time | Time to complete a process | Shows efficiency improvements |

Error Rate | Number of mistakes | Tracks quality and consistency |

Customer Satisfaction | Survey or feedback scores | Reflects service improvements |

Cost per Transaction | Average cost per task | Reveals cost savings |

Teams should collect data regularly. They can use dashboards, spreadsheets, or specialized software to track progress. Visual tools like charts and graphs make it easy to spot trends and share results with stakeholders.

Regular reviews keep everyone focused. Teams should schedule weekly or monthly check-ins to discuss progress. These meetings help identify roadblocks and celebrate wins. If a process does not meet expectations, teams can adjust their approach quickly.

Tip: Celebrate small wins to keep teams motivated. Recognition boosts morale and encourages continued effort.

Feedback plays a key role in monitoring. Teams should gather input from employees and customers. This feedback helps spot hidden issues and find new improvement opportunities. Open communication ensures that everyone feels involved and valued.

Organizations may face challenges during this step. Data collection can become inconsistent. Teams might lose focus over time. To overcome these issues, leaders should assign clear responsibilities for tracking and reporting. They should also provide training on using monitoring tools.

A checklist for effective monitoring:

Define clear KPIs

Collect and review data regularly

Use visual tools for easy understanding

Hold regular progress meetings

Gather feedback from all stakeholders

Adjust strategies based on results

Monitoring progress turns process improvement into a continuous journey. Teams learn from their results and keep moving forward. This approach helps organizations achieve lasting success and adapt to new challenges.

Sustaining Improvement

Continuous Improvement Culture

A continuous improvement culture helps organizations maintain progress long after the initial changes. Teams that value ongoing learning and adaptation see better results over time. Leaders play a central role by setting clear expectations and supporting improvement at every level. When leaders stay engaged, employees feel encouraged to share ideas and take ownership of their work.

Staff involvement stands out as a key factor. Employees who help design and test new processes become invested in the outcome. They notice problems early and suggest practical solutions. Regular team meetings and open communication channels keep everyone aligned. Organizations that celebrate small wins build momentum and keep motivation high.

A strong improvement culture also relies on clear goals and performance monitoring. Teams use visual management systems, such as process control boards, to track progress. These tools make results visible and help teams respond quickly to issues. Standard work documentation ensures everyone follows best practices, which supports consistency and quality.

Organizations that focus on leadership commitment, staff engagement, and clear communication create a foundation for lasting improvement.

Technology and Automation

Technology and automation support sustained improvement by making processes more efficient and reliable. Automated systems handle repetitive tasks, which reduces errors and frees employees to focus on higher-value work. For example, automated alerts can notify teams when performance drops, allowing for quick action.

Digital tools help teams collect and analyze data in real time. Dashboards display key metrics, making it easy to spot trends and identify areas for further improvement. Visual management systems, such as digital performance boards, promote transparency and accountability.

Organizations that invest in technology also gain flexibility. They can adapt quickly to changes in demand or regulations. Automated workflows ensure that best practices are followed every time. This consistency helps maintain high performance even as teams grow or change.

A well-chosen technology infrastructure supports ongoing training and communication. Employees can access resources, share feedback, and learn new skills through digital platforms. This approach keeps everyone connected and informed.

Ongoing Training

Ongoing training ensures that employees have the skills and knowledge needed to sustain improvements. Regular training sessions help staff stay up to date with new processes and technologies. When employees understand why changes matter, they become more engaged and confident in their roles.

Training programs should include hands-on practice, clear instructions, and opportunities for feedback. Leaders can assign responsibilities for monitoring performance and providing support. This approach helps teams maintain high standards and adapt to new challenges.

Organizations that invest in ongoing training see better results. Staff feel prepared to handle changes and contribute ideas for further improvement. Training also supports a culture of continuous learning, which keeps teams motivated and focused on long-term goals.

Sustained improvement depends on leadership commitment, staff involvement, and a strong focus on learning and adaptation. Organizations that prioritize these elements build a resilient foundation for future success.

Feedback and Iteration

Feedback and iteration help organizations keep their process improvements on track. Teams use feedback to learn what works and what needs change. Iteration means making small adjustments based on what the team learns. This cycle helps organizations stay flexible and improve over time.

Teams collect feedback from many sources. They ask employees, customers, and partners for their opinions. Surveys, suggestion boxes, and regular meetings give people a chance to share ideas. Some organizations use digital tools to gather feedback quickly. For example, a company might use an online form after each project to ask team members what went well and what could improve.

Tip: Teams should encourage honest feedback. Leaders can set the example by listening and acting on suggestions.

After collecting feedback, teams review the information. They look for patterns and common issues. A team might notice that several employees mention the same problem. This signals an area that needs attention. Teams then plan small changes to address these issues.

Iteration starts when teams test new ideas. They make one change at a time and watch the results. If the change works, they keep it. If not, they try something else. This process repeats until the team finds the best solution. Iteration helps teams avoid big mistakes because they test changes before rolling them out to everyone.

A simple feedback and iteration cycle looks like this:

Collect feedback from all stakeholders.

Review and analyze the feedback.

Plan a small change or improvement.

Test the change in a real setting.

Measure the results.

Decide to keep, adjust, or remove the change.

Repeat the cycle.

Step | Action Example |

|---|---|

Collect | Employee survey after process change |

Review | Team meeting to discuss results |

Plan | Choose one improvement to test |

Test | Pilot the change in one department |

Measure | Track time saved or errors reduced |

Decide | Keep or adjust based on data |

Feedback and iteration keep organizations moving forward. Teams learn from mistakes and build on successes. This approach creates a culture where improvement never stops. Organizations that use feedback and iteration stay competitive and ready for new challenges.

Business process improvement methodologies help organizations achieve lasting success. A structured, step-by-step approach leads to better results and fewer mistakes. Teams that review and improve their processes often see higher efficiency and stronger customer satisfaction.

Evaluate current workflows.

Choose the right methodology.

Commit to ongoing improvement.

Continuous improvement and adaptability keep organizations competitive. Now is the time to take action and drive growth.

FAQ

What is the main goal of business process improvement?

The main goal is to make processes work better. Teams want to reduce waste, save money, and improve quality. They also want to make customers happier and help the company grow.

How often should organizations review their processes?

Teams should review processes regularly. Many experts suggest checking at least once a year. Some industries may need more frequent reviews, especially if rules or customer needs change quickly.

Can small businesses use these methodologies?

Yes, small businesses can use process improvement methods. They often start with simple tools like PDCA or Kaizen. These approaches help teams find quick wins and build a culture of improvement.

What is the difference between Lean and Six Sigma?

Lean focuses on removing waste and speeding up work. Six Sigma aims to reduce mistakes and make results more consistent. Many companies use both together for better results.

How do teams measure success in process improvement?

Teams use key performance indicators (KPIs) to track progress. Common KPIs include cycle time, error rates, and customer satisfaction scores. These numbers show if changes make a real difference.

Do employees need special training for process improvement?

Most teams need some training. Training helps employees understand new tools and methods. It also builds confidence and makes it easier to work together on changes.

What challenges do organizations face during implementation?

Teams often face resistance to change, lack of clear goals, or limited resources. Strong leadership, good communication, and regular feedback help overcome these challenges.

Is technology required for process improvement?

Technology helps but is not always required. Many improvements start with simple changes. Digital tools can make tracking and communication easier as teams grow.