A Beginner's Guide to Business Process Improvement Methodologies

Business Process Improvement Methodologies offer structured approaches to analyzing and enhancing a Process within organizations. By focusing on Optimization Steps, these methodologies aim to streamline workflows, eliminate inefficiencies, and deliver consistent results. Tools like the Kanban system and standardized workflows enable businesses to prevent bottlenecks, maintain operational consistency, and achieve higher efficiency, ultimately reducing costs.

Improved Processes not only lower expenses but also elevate Customers' satisfaction. Faster service delivery, real-time updates, and seamless operations contribute to superior customer experiences across various industries. Whether for a small business or a global enterprise, adopting Business Process Improvement Methodologies drives innovation and adaptability, ensuring success in today’s competitive markets.

Key Takeaways

Business Process Improvement Methods help businesses work better and faster.

Using these methods can save money and improve efficiency.

Popular methods include Lean, Six Sigma, Agile, and Quality Management.

Clear and measurable goals are key to making these methods work.

Employees should share ideas to solve problems and make changes easier.

Start with small changes to build trust and grow over time.

Use technology to make work easier and handle tough tasks.

Check progress often and use data to keep improving.

What Are Business Process Improvement Methodologies?

Definition and Purpose

Business Process Improvement Methodologies are structured approaches designed to optimize workflows, eliminate inefficiencies, and enhance overall performance. These methodologies aim to identify bottlenecks, improve compliance with industry standards, and boost customer satisfaction. They serve as problem-solving tools that help organizations streamline their operations and achieve measurable outcomes.

Several frameworks define these methodologies:

Agile management focuses on cross-functional teams working in short cycles to improve processes.

Lean management emphasizes waste reduction and efficiency through techniques like Kaizen and 5S.

Six Sigma uses statistical tools and the DMAIC framework to minimize defects.

Theory of Constraints identifies and addresses the most critical constraints in a process.

Total Quality Management (TQM) prioritizes continuous improvement and customer satisfaction through data-driven decisions.

Plan-Do-Check-Act (PDCA) employs a cyclical approach to problem-solving and process enhancement.

These methodologies provide a foundation for businesses to adapt to changing market demands while maintaining operational excellence.

Key Benefits for Businesses

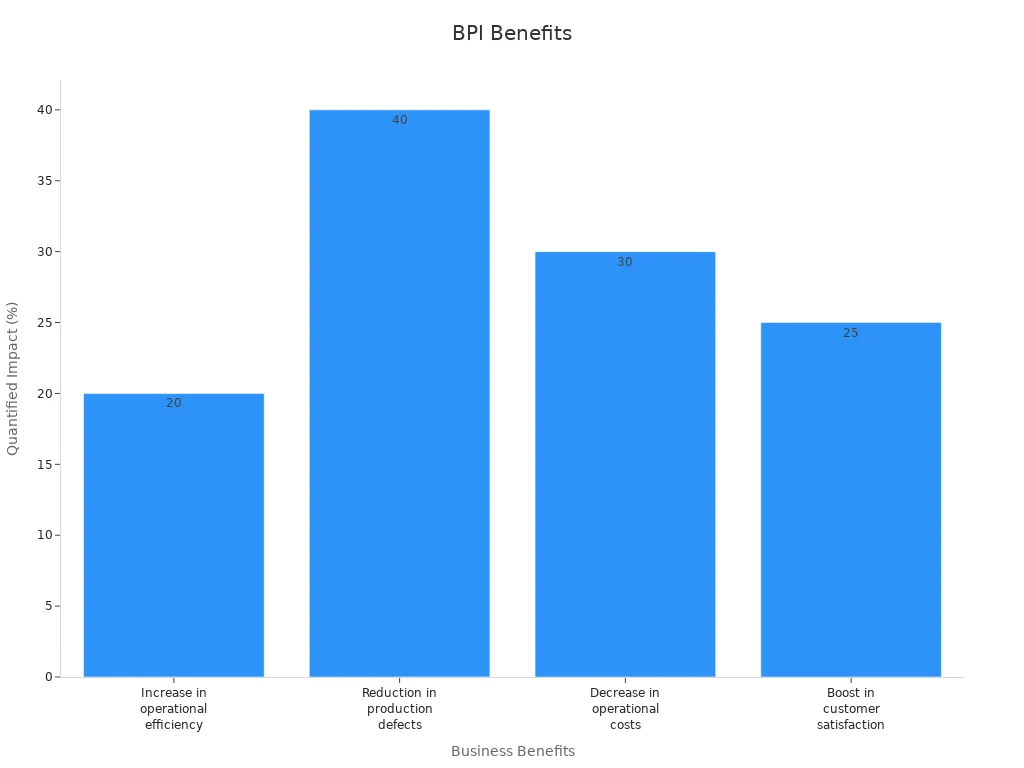

Implementing Business Process Improvement Methodologies offers numerous advantages. These include increased efficiency, cost savings, and enhanced customer satisfaction. Research highlights the following quantified benefits:

Benefit | Quantified Impact |

|---|---|

Increase in operational efficiency | |

Reduction in production defects | 40% reduction over five years |

Decrease in operational costs | 30% decrease over five years |

Boost in customer satisfaction | 25% increase over five years |

For example, methodologies like Kaizen and TQM focus on continuous improvement, leading to fewer complaints and higher satisfaction rates. Similarly, Six Sigma's data-driven approach reduces defects, ensuring consistent product quality. These benefits not only improve internal processes but also strengthen a company's competitive edge in the market.

Common Challenges in Business Processes

Despite their advantages, organizations often face challenges when implementing Business Process Improvement Methodologies. These challenges can hinder progress and reduce the effectiveness of improvement efforts. Common issues include:

Challenge | Evidence |

|---|---|

"They sometimes miss critical information that would have an impact on the effectiveness of that specific business process." [RP01] | |

Ineffective employee assessment | "Initiatives should be better aligned with our rewards recognition process. There is frustration on both sides..." [RP02] [RP08] |

Ineffective monitoring capabilities | "We have not, and I think that might be one of our failings..." [RP08] |

Resistance to change | "They are only now starting to speak up because someone has left, and now realize that they have an issue." [RP06] |

Resistance to change is a particularly significant barrier. Employees may hesitate to adopt new processes due to fear of the unknown or lack of proper training. Additionally, ineffective monitoring systems can prevent organizations from tracking progress and identifying areas for further improvement. Addressing these challenges requires clear communication, robust training programs, and a commitment to continuous evaluation.

Overview of Key Methodologies

Six Sigma

Core Principles of Six Sigma

Six Sigma is a data-driven methodology that focuses on reducing defects and variations in business processes. It uses the DMAIC framework, which stands for Define, Measure, Analyze, Improve, and Control. This structured approach ensures that organizations can identify root causes of inefficiencies and implement sustainable solutions. Six Sigma emphasizes statistical analysis and process control to achieve near-perfect quality levels.

Benefits of Six Sigma

Organizations adopting Six Sigma experience significant improvements in quality and efficiency. For example, Motorola implemented Six Sigma and achieved over $16 billion in savings while earning the Malcolm Baldrige National Quality Award. Other benefits include:

Reduction in process defects.

Enhanced customer satisfaction due to consistent product quality.

Cost savings through streamlined operations.

Common Use Cases for Six Sigma

Six Sigma is widely used in manufacturing, healthcare, and service industries. It is particularly effective in:

Reducing production defects in manufacturing.

Improving patient care processes in hospitals.

Enhancing customer service workflows in call centers.

Lean Manufacturing

Core Principles of Lean

Lean Manufacturing focuses on eliminating waste and maximizing value for customers. It operates on principles such as continuous improvement (Kaizen), just-in-time production, and respect for people. By identifying and removing non-value-adding activities, Lean ensures that resources are used efficiently.

Benefits of Lean

Lean Manufacturing delivers measurable outcomes. For instance, Toyota's Lean initiatives reduced production costs, improved product quality, and shortened delivery times. Additional benefits include:

Faster production cycles.

Lower operational costs.

Improved employee productivity.

Common Use Cases for Lean

Lean is commonly applied in industries like automotive, retail, and logistics. Examples include:

Streamlining supply chain operations.

Reducing inventory waste in warehouses.

Enhancing production efficiency in factories.

Agile Methodologies

Core Principles of Agile

Agile methodologies prioritize flexibility, collaboration, and customer feedback. Teams work in short cycles, known as sprints, to deliver incremental improvements. Agile encourages adaptability, allowing businesses to respond quickly to changing market demands.

Benefits of Agile

Agile methodologies improve team collaboration and product delivery speed. Research shows that Agile groups on LinkedIn have over 37,000 members, reflecting its widespread adoption. Key benefits include:

Faster time-to-market for products.

Improved team communication and morale.

Enhanced ability to meet customer needs.

Common Use Cases for Agile

Agile is widely used in software development, marketing, and project management. Common applications include:

Developing and releasing software updates.

Managing digital marketing campaigns.

Coordinating cross-functional projects.

Total Quality Management (TQM)

Core Principles of TQM

Total Quality Management (TQM) emphasizes continuous improvement and customer satisfaction. It operates on the belief that quality is everyone's responsibility within an organization. TQM integrates quality-focused practices into every aspect of business operations. Key principles include:

Customer Focus: Organizations prioritize understanding and meeting customer needs.

Employee Involvement: Employees at all levels contribute to quality improvement initiatives.

Process Approach: Processes are optimized to ensure consistent and efficient outcomes.

Data-Driven Decisions: Decisions rely on accurate data and analysis rather than assumptions.

Continuous Improvement: Businesses strive for incremental improvements in products and services.

These principles create a culture where quality becomes a shared goal, fostering collaboration and accountability.

Benefits of TQM

TQM delivers significant advantages for organizations. It enhances product quality, reduces waste, and improves customer satisfaction. Companies adopting TQM often experience:

Higher Customer Loyalty: Consistent quality builds trust and repeat business.

Cost Savings: Efficient processes reduce operational expenses.

Employee Engagement: Involvement in quality initiatives boosts morale and productivity.

For example, Toyota's TQM practices helped the company achieve global recognition for reliability and innovation. By focusing on quality at every level, businesses can strengthen their competitive position.

Common Use Cases for TQM

TQM is widely applied across industries. Common use cases include:

Manufacturing: Ensuring product consistency and reducing defects.

Healthcare: Improving patient care and safety standards.

Education: Enhancing teaching methods and administrative processes.

Organizations use TQM to align their operations with customer expectations, ensuring long-term success.

Continuous Improvement (Kaizen)

Core Principles of Kaizen

Kaizen, a Japanese term meaning "change for the better," focuses on small, incremental improvements. It encourages employees to identify inefficiencies and propose solutions. Core principles include:

Employee Empowerment: Workers actively participate in improvement efforts.

Standardization: Processes are standardized to maintain consistency.

Waste Reduction: Non-value-adding activities are eliminated.

Collaboration: Teams work together to achieve shared goals.

Kaizen fosters a proactive mindset, enabling organizations to adapt to challenges and opportunities.

Benefits of Kaizen

Kaizen offers numerous benefits. It improves efficiency, reduces costs, and enhances employee satisfaction. Key advantages include:

Improved Productivity: Streamlined processes increase output.

Cost Reduction: Waste elimination lowers expenses.

Employee Engagement: Involvement in decision-making boosts morale.

For instance, companies like Toyota and Honda use Kaizen to refine their production systems, achieving global success through continuous improvement.

Common Use Cases for Kaizen

Kaizen is commonly applied in manufacturing, logistics, and service industries. Examples include:

Production Lines: Reducing downtime and optimizing workflows.

Supply Chains: Enhancing delivery speed and accuracy.

Customer Service: Improving response times and satisfaction rates.

Kaizen's focus on small changes makes it accessible and effective for businesses of all sizes.

Plan-Do-Check-Act (PDCA) Cycle

Core Principles of PDCA

The Plan-Do-Check-Act (PDCA) cycle is a systematic approach to problem-solving and process improvement. It consists of four stages:

Plan: Identify problems and develop strategies to address them.

Do: Implement the planned solutions on a small scale.

Check: Evaluate the effectiveness of the solutions.

Act: Apply successful changes on a larger scale and standardize them.

PDCA promotes a structured and iterative approach to achieving continuous improvement.

Benefits of PDCA

PDCA helps organizations improve efficiency and adapt to changing conditions. Benefits include:

Structured Problem-Solving: Clear steps ensure thorough analysis and implementation.

Risk Reduction: Testing solutions on a small scale minimizes risks.

Scalability: Successful changes can be applied across the organization.

For example, PDCA is widely used in project management to refine workflows and achieve better outcomes.

Common Use Cases for PDCA

PDCA is versatile and applicable across industries. Common use cases include:

Manufacturing: Improving production processes and quality control.

Healthcare: Enhancing patient care and operational efficiency.

Retail: Optimizing inventory management and customer service.

By following the PDCA cycle, organizations can achieve sustainable improvements and maintain a competitive edge.

Business Process Reengineering (BPR)

Core Principles of BPR

Business Process Reengineering (BPR) focuses on fundamentally rethinking and redesigning business processes to achieve dramatic improvements in performance. Unlike incremental improvement methods, BPR aims for radical changes that transform how work is done.

Key principles of BPR include:

Customer-Centric Approach: Processes are redesigned to deliver maximum value to customers.

Process Orientation: Instead of focusing on individual tasks, BPR emphasizes end-to-end processes.

Use of Technology: Advanced tools and systems play a critical role in enabling process transformation.

Challenging Assumptions: Organizations question existing practices and explore innovative alternatives.

Cross-Functional Collaboration: Teams from different departments work together to streamline workflows.

BPR encourages organizations to break free from traditional methods and adopt bold strategies for achieving efficiency and effectiveness.

Tip: BPR works best when organizations are open to change and willing to embrace new ways of operating.

Benefits of BPR

Organizations that implement BPR often experience significant benefits. These improvements can impact various aspects of operations, including cost, quality, and speed.

Some notable benefits include:

Cost Reduction: Streamlined processes eliminate redundancies, reducing operational expenses.

Improved Productivity: Employees focus on value-adding activities, increasing overall efficiency.

Enhanced Customer Satisfaction: Faster and more reliable services lead to better customer experiences.

Increased Agility: Organizations become more adaptable to market changes and customer demands.

Innovation Opportunities: BPR fosters a culture of creativity and continuous improvement.

For example, Ford Motor Company used BPR to overhaul its accounts payable process. By replacing manual workflows with automated systems, the company reduced its workforce in that department by 75% while improving accuracy and speed.

Common Use Cases for BPR

BPR is widely applicable across industries. It is particularly effective in scenarios where traditional processes fail to meet organizational goals.

Common use cases include:

Manufacturing: Redesigning production lines to minimize waste and improve output.

Healthcare: Streamlining patient care processes to reduce wait times and enhance service quality.

Banking: Automating loan approval workflows to improve processing speed and accuracy.

Retail: Optimizing supply chain operations to ensure timely delivery and inventory management.

Government Services: Simplifying bureaucratic procedures to improve public service delivery.

By focusing on radical transformation, BPR enables organizations to achieve breakthroughs in performance and competitiveness.

How to Choose the Right Methodology

Assessing Your Business Needs

Choosing the right business process improvement methodology begins with understanding the unique needs of your organization. Each business operates within a distinct framework of goals, challenges, and resources. To identify the most suitable methodology, organizations must evaluate their current processes and define their objectives clearly.

A best practices checklist can guide this evaluation:

Define Objectives Clearly: Establish measurable goals that align with the organization’s overall vision.

Map Existing Processes: Create a visual representation of workflows to pinpoint inefficiencies and areas for improvement.

For example, companies like Intel and Medtronic have demonstrated the importance of strategic foresight and data analysis in meeting business needs. Their success highlights how a thorough understanding of organizational requirements can drive effective decision-making.

Comparing Methodologies Based on Goals

Different methodologies offer unique advantages depending on the goals of the organization. Comparative analysis helps businesses identify which approach aligns best with their objectives.

Criteria | Description |

|---|---|

Evaluates economic viability and profitability of alternatives. | |

Strategic Alignment | Ensures decisions reflect the organization’s vision and competitive goals. |

Risk Assessment | Assesses operational, regulatory, and reputational risks. |

Stakeholder Engagement | Considers customer commitment and employee involvement. |

Technical Knowledge | Evaluates expertise and technological compatibility. |

Organizations can use these criteria to compare methodologies such as Lean, Six Sigma, Kaizen, and Kanban. For instance, Lean is ideal for waste reduction, while Six Sigma excels in minimizing defects. Comparative studies also reveal how benchmarking against industry standards can help businesses refine their choices. This process involves evaluating performance metrics, market trends, and customer feedback to ensure alignment with organizational goals.

Factors to Consider (e.g., team size, industry, resources)

Several factors influence the selection of a business process improvement methodology. Team size, industry type, and available resources play a critical role in determining the feasibility and effectiveness of each approach.

Team Size: Smaller teams may benefit from methodologies like Kaizen, which focus on incremental improvements. Larger teams might find Agile or Lean Six Sigma more suitable due to their scalability.

Industry Type: Manufacturing industries often prefer Lean and Six Sigma for their focus on efficiency and quality. Service-based industries may opt for Agile or TQM to enhance customer satisfaction.

Resources: Organizations with limited budgets might prioritize methodologies that require minimal investment, such as PDCA or Kaizen. Those with access to advanced technology and skilled personnel can leverage methodologies like BPR for transformative changes.

By considering these factors, businesses can ensure that their chosen methodology aligns with their operational capabilities and strategic goals. This tailored approach maximizes the likelihood of success and minimizes potential risks.

Steps to Implement a Business Process Improvement Methodology

Identifying the Problem Areas

The first step in implementing business process improvement methodologies involves identifying problem areas within existing workflows. Organizations must conduct a thorough review of their operations to pinpoint inefficiencies and bottlenecks. For example, a retail chain might track customer wait times and inventory turnover rates to uncover areas needing improvement. Similarly, a manufacturing plant could analyze machine downtime to identify opportunities for optimization.

A systematic approach ensures no critical issues are overlooked. Businesses can follow these best practices:

Review current processes to understand their structure and performance.

Analyze data to identify recurring issues, such as delays or errors.

Engage employees to gather insights about challenges they face daily.

By addressing these problem areas, organizations lay the groundwork for meaningful improvements.

Setting Clear Goals and Objectives

Once problem areas are identified, setting clear goals and objectives becomes essential. These targets should align with broader business objectives and be specific, measurable, and time-bound. For instance, a manufacturing plant might aim to reduce machine downtime by 15% over a quarter. A retail chain could set a goal to decrease production waste by 20% within six months.

To ensure success, organizations should:

Define objectives that are realistic and achievable.

Break down larger goals into smaller, actionable steps.

Monitor progress regularly through performance reviews and data analysis.

Weekly review meetings can help teams stay on track and address emerging issues promptly. This structured approach ensures that improvement efforts remain focused and effective.

Training Your Team

Training plays a crucial role in the successful implementation of any business process improvement methodology. Employees need to understand the new processes and tools to contribute effectively. For example, methodologies like Kanban and PDCA require team members to use visual workflow tools and cyclical problem-solving techniques.

Organizations can enhance training effectiveness by:

Providing hands-on workshops to familiarize employees with new methods.

Offering ongoing support through mentorship and resources.

Encouraging collaboration to foster a culture of continuous learning.

A well-trained team not only ensures smooth implementation but also drives long-term success. Employees who feel confident in their roles are more likely to embrace change and contribute to sustained improvements.

Tip: Standardizing successful processes after training helps maintain consistency and ensures sustainability.

Monitoring and Measuring Progress

Monitoring and measuring progress is essential for ensuring the success of any business process improvement methodology. Organizations must track their efforts to determine whether the implemented changes are achieving the desired outcomes. This process involves using reliable metrics, analyzing data, and making adjustments based on findings.

To measure progress effectively, businesses should validate metrics and employ strategies that minimize unintended consequences. Independent data sources provide unbiased insights, while multiple related measures offer a comprehensive view of performance. For example, tracking both customer satisfaction and operational efficiency can reveal how improvements impact different aspects of the business.

Key techniques for monitoring progress include:

Progress validation: Verifying that reported progress aligns with actual work completed.

Performance monitoring: Analyzing project performance over time to identify potential issues.

Tracking milestones and deliverables: Observing the completion of key stages in the project.

Resource allocation and utilization: Ensuring resources are used effectively throughout the process.

Progress towards goals and KPIs: Evaluating how well the project meets defined objectives.

Schedule and timeline adherence: Checking regularly to ensure activities remain on schedule.

Organizations can also follow a structured approach to define and monitor their goals:

Identify key objectives through a consensus-building process.

Validate metrics to ensure they accurately measure progress toward these objectives.

Implement strategies that reduce the risk of unintended outcomes.

For instance, a manufacturing company might monitor production cycle times and defect rates to assess the impact of Lean principles. Similarly, a healthcare provider could track patient wait times and treatment outcomes to evaluate improvements in service delivery.

Regular reviews of progress help organizations stay on track. Teams should analyze data frequently and compare results against benchmarks or key performance indicators (KPIs). If discrepancies arise, adjustments can be made to refine processes and achieve better results. This iterative approach ensures continuous improvement and long-term success.

Tip: Combining qualitative feedback from employees and customers with quantitative metrics provides a well-rounded understanding of progress. This dual approach helps identify both visible and hidden challenges.

By prioritizing monitoring and measurement, businesses can ensure their improvement efforts deliver tangible benefits. This practice not only enhances operational efficiency but also builds a culture of accountability and continuous growth.

Common Mistakes to Avoid

Even with the best intentions, organizations often encounter pitfalls when implementing business process improvement (BPI) methodologies. Recognizing these common mistakes can help businesses avoid setbacks and achieve their goals more effectively.

Lack of Clear Goals

A lack of clear goals often undermines the success of BPI initiatives. Without well-defined objectives, employees may struggle to understand what is expected of them. This confusion can lead to underperformance and disengagement. For instance, when employees do not have a clear direction, they may focus on tasks that do not align with the organization’s priorities.

Tip: Setting specific, measurable, and time-bound goals ensures that everyone works toward the same outcomes.

Research shows that 60–70% of BPI projects fail, often due to unclear objectives. Organizations that fail to acknowledge risks or define their goals adequately are more likely to encounter challenges during implementation.

Key Insights | Description |

|---|---|

High Failure Rate | 60–70% of BPI projects fail and are not completed due to various reasons. |

Lack of Risk Acknowledgment | Organizations often overlook risks that can hinder successful implementation. |

Focus on Soft Factors | Insufficient exploration of culture and employee motivation in BPI efforts. |

By establishing clear goals and addressing potential risks, businesses can improve their chances of success.

Overcomplicating the Process

Overcomplicating processes is another common mistake that reduces the effectiveness of improvement efforts. Complex workflows can overwhelm employees, making it harder for them to achieve their objectives. Simplicity is key to ensuring that processes are easy to understand and implement.

For example, organizations that introduce too many steps or tools may inadvertently create confusion. Employees may spend more time navigating the process than completing their tasks. This inefficiency can negate the benefits of the improvement initiative.

Overcomplicated processes reduce effectiveness, making it harder for employees to achieve their objectives.

Streamlined workflows improve efficiency and employee satisfaction.

Note: Simplifying processes does not mean sacrificing quality. Instead, it involves focusing on essential steps that add value.

Organizations should regularly review their workflows to identify unnecessary complexities. By doing so, they can create processes that are both efficient and user-friendly.

Ignoring Employee Feedback

Ignoring employee feedback is a critical mistake that can derail BPI initiatives. Employees often have valuable insights into the challenges and inefficiencies within their workflows. When managers fail to listen, they miss opportunities to address these issues effectively.

Studies reveal that 60% of employees feel their managers do not listen to them often enough. This lack of communication can lead to frustration and disengagement. Employees who feel unheard are less likely to support improvement efforts, reducing the initiative’s overall impact.

The absence of employee feedback can result in missed opportunities for improvement.

Engaging employees fosters a sense of ownership and collaboration.

Tip: Regular feedback sessions and open communication channels encourage employees to share their ideas and concerns.

By involving employees in the decision-making process, organizations can build a culture of trust and collaboration. This approach not only enhances the effectiveness of BPI initiatives but also boosts employee morale.

Avoiding these common mistakes requires careful planning and a commitment to continuous improvement. By addressing these challenges proactively, businesses can maximize the benefits of their process improvement efforts.

Actionable Tips for Beginners

Start Small and Scale Gradually

Beginners often achieve better results by starting with small, manageable changes. Tackling smaller projects allows teams to focus on specific areas without overwhelming resources or personnel. For example, a retail business might begin by optimizing inventory management before expanding to broader supply chain improvements.

A structured approach ensures success:

Start with a clear research question: Define a focused question to guide your analysis and align efforts with your goals.

Document your process: Keep detailed notes on methodologies, data collection, and sampling methods. This practice aids reproducibility and helps identify issues.

Visualize your data: Use graphs and plots to understand trends and detect anomalies. Tools like scatter plots and histograms are particularly useful.

Seek feedback: Engage with peers or mentors to refine your approach and prevent oversights.

Small-scale improvements build confidence and provide valuable insights for scaling efforts. Teams can use lessons learned to tackle larger projects with greater efficiency and effectiveness.

Tip: Incremental changes reduce risks and allow organizations to adapt gradually, ensuring long-term success.

Leverage Technology and Tools

Technology plays a vital role in streamlining business processes. Tools like workflow automation software, data visualization platforms, and project management applications simplify complex tasks and enhance productivity. However, successful adoption requires careful planning and management.

Studies show that only 16% of users fully adopt new technologies due to unmanaged changes. Additionally, 37% of construction professionals reported investing in software that was never utilized. These statistics highlight the importance of effective implementation plans.

Organizations can maximize their digital investments by:

Creating a technology adoption plan: Outline clear steps for integrating tools into workflows.

Providing training: Equip employees with the skills needed to use new technologies effectively.

Monitoring usage: Track adoption rates and address barriers to ensure full utilization.

Leadership support also plays a critical role in technology adoption. The Prosci ADKAR Model emphasizes guiding individuals through transitions, while the Prosci Change Triangle highlights the importance of project health and leadership sponsorship. Strong leadership boosts team morale and ensures momentum during digital transformation efforts.

Note: Investing in the right tools and fostering a culture of adaptability ensures that technology delivers measurable benefits.

Seek Expert Guidance When Needed

Expert guidance accelerates the learning curve for beginners. Professionals with experience in business process improvement can provide valuable insights, helping organizations avoid common pitfalls. For instance, consultants specializing in Lean or Six Sigma methodologies can guide teams through implementation, ensuring alignment with best practices.

Engaging experts offers several advantages:

Access to proven strategies: Experts bring tried-and-tested methods that reduce trial-and-error efforts.

Customized solutions: Professionals tailor recommendations to address specific organizational challenges.

Ongoing support: Consultants provide mentorship and feedback, ensuring continuous improvement.

Organizations should also leverage online communities and forums to connect with industry professionals. Peer reviews and collaborative discussions often uncover innovative ideas and solutions.

Tip: Seeking expert advice early in the process saves time and resources, enabling teams to focus on achieving their goals.

By starting small, leveraging technology, and seeking expert guidance, beginners can navigate the complexities of business process improvement with confidence. These actionable tips provide a solid foundation for driving efficiency and achieving sustainable growth.

Business process improvement methodologies play a pivotal role in driving efficiency and fostering growth. They enable organizations to streamline workflows, reduce waste, and enhance customer satisfaction. Research highlights their transformative impact:

Evidence Type | Statistic/Insight |

|---|---|

Efficiency Gains | Less than 20% of an organization’s processes significantly impact its competitive position. |

Customer Satisfaction | |

Employee Productivity | 74% of companies implementing BPM to enhance staff satisfaction reported a positive impact on their business. |

Selecting the right methodology tailored to specific business needs ensures maximum effectiveness. Businesses should begin by analyzing their current processes to identify inefficiencies. This first step lays the foundation for meaningful improvements and long-term success.

FAQ

What is the best methodology for small businesses?

Small businesses often benefit from methodologies like Kaizen or PDCA. These approaches focus on incremental improvements and require fewer resources. They are easy to implement and encourage employee involvement, making them ideal for smaller teams with limited budgets.

How long does it take to see results from process improvement?

The timeline varies depending on the methodology and scope. Small-scale improvements, such as those using Kaizen, may show results within weeks. Larger initiatives, like Business Process Reengineering (BPR), can take several months to deliver measurable outcomes.

Can multiple methodologies be used together?

Yes, combining methodologies can enhance results. For example, Lean and Six Sigma often work well together to reduce waste and improve quality. However, organizations should ensure compatibility and align the combined approach with their goals.

Do these methodologies apply to non-manufacturing industries?

Absolutely! Methodologies like Agile and TQM are widely used in service sectors, healthcare, and education. They help streamline workflows, improve customer satisfaction, and enhance operational efficiency across various industries.

What role does technology play in process improvement?

Technology simplifies implementation by automating workflows, tracking progress, and analyzing data. Tools like project management software and data visualization platforms enhance efficiency and decision-making. However, proper training and adoption plans are essential for success.

How do you measure the success of a methodology?

Success is measured using key performance indicators (KPIs) such as cost savings, defect reduction, and customer satisfaction. Regular monitoring and data analysis ensure that the methodology achieves its intended goals.

What if employees resist the changes?

Resistance to change is common. Organizations can address this by involving employees early, providing training, and communicating the benefits of the new processes. A supportive culture encourages acceptance and collaboration.

Are these methodologies expensive to implement?

Costs depend on the methodology and scale of implementation. Approaches like Kaizen and PDCA are cost-effective, while methodologies like BPR may require significant investment in technology and training. Organizations should assess their resources before choosing a methodology.