Best Practices for Lean Six Sigma Process Mapping

Lean Six Sigma Process Mapping gives teams a clear view of how work flows from start to finish. This visual roadmap allows teams to spot bottlenecks, delays, and steps that do not add value for clients or customers.

Value Stream Mapping often reveals that less than 10% of lead time adds value, highlighting waste.

Control charts and Statistical Process Control help teams detect process shifts early, reducing defects by as much as 67% in some industries.

By following Optimization Steps and using data-driven tools, organizations can improve efficiency and quality. Teams should consider how these best practices fit into their own processes.

Key Takeaways

Lean Six Sigma Process Mapping visually shows each step in a workflow to help teams find waste, delays, and errors.

Using different map types like SIPOC, Value Stream, and Swimlane helps teams understand processes from big-picture to detailed views.

Setting clear goals and defining process boundaries keeps mapping focused and prevents scope creep.

Involving the right people, including subject matter experts and frontline staff, ensures accurate and useful process maps.

Collecting real data and observing work through Gemba walks reveal hidden problems and improve map accuracy.

Capturing exceptions and variations in the process prepares teams for real-world challenges and supports better solutions.

Generating and prioritizing improvement ideas with team input leads to practical changes that reduce waste and boost efficiency.

Regularly reviewing, updating, and tracking process maps helps sustain improvements and fosters continuous learning.

Lean Six Sigma Process Mapping

Definition

Lean Six Sigma Process Mapping is a visual tool that helps teams understand and improve how work gets done. It shows each step in a process, making it easier to spot problems and find ways to make things better. Quality management organizations define Lean Six Sigma Process Mapping as a method that increases efficiency, reduces mistakes, and supports the DMAIC framework—Define, Measure, Analyze, Improve, and Control. Teams use this tool to identify the process, collect data, involve the right people, draw the map, share it, and update it as needed.

Tip: Regularly updating process maps ensures they reflect the current way work happens, which helps teams keep improving.

Importance

Lean Six Sigma Process Mapping acts as a visual roadmap for process improvement. It documents each workflow, step, and task, making complex procedures easier to understand. By mapping out the process, teams can see where defects, delays, or waste occur. This clear view helps everyone understand the process and work together to fix problems. When teams create both current and future state maps, they can plan changes that lead to better results. Process mapping also supports the DMAIC methodology. In the Measure phase, it helps teams see the actual steps and gather data. During the Improve phase, it guides teams as they make changes and check results. This approach leads to better communication, faster problem-solving, and ongoing improvement.

Process mapping played a key role in improving healthcare screening during the COVID-19 pandemic. Teams used it to reduce wait times, boost productivity, and keep people safe. By understanding the process, they made quick changes that saved time and money.

Types of Maps

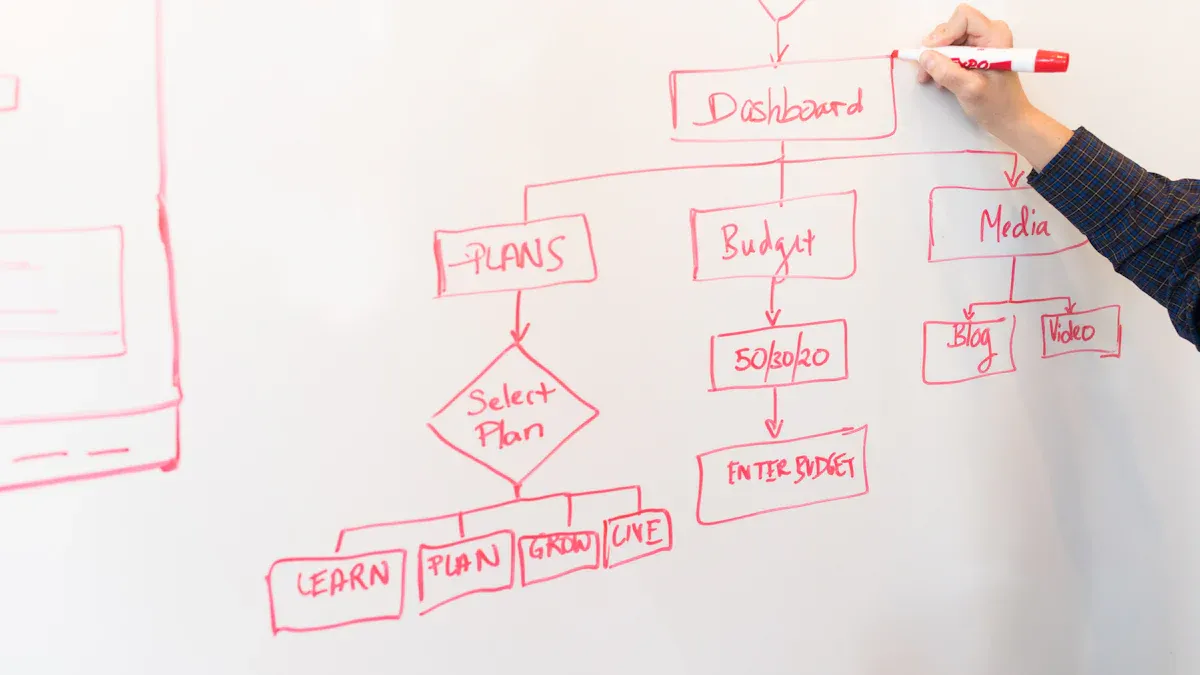

Teams use several types of maps in Lean Six Sigma Process Mapping, each with a special purpose:

SIPOC Map: Breaks down the process into Suppliers, Inputs, Process, Outputs, and Customers. Teams use it at the start of a project to see the big picture.

High Level Map: Shows the main steps without too much detail. It helps leaders and teams understand the overall flow.

Detailed Map: Explains every step in the process. Teams use it to find exact problems and make deep improvements.

Swimlane Map: Divides the process by department or team. It shows who does what and helps spot handoffs or bottlenecks.

Value Stream Map: Focuses on value-adding and non-value-adding steps. Teams use it to find and remove waste.

Spaghetti Diagram: Shows the physical movement of people or materials. It helps teams see if the layout causes extra work.

Current State and Future State Maps: Show how things work now and how they should work after improvements.

Map Type | Main Use |

|---|---|

SIPOC | Big-picture overview |

High Level | Simple communication |

Detailed | Deep analysis |

Swimlane | Clarifies roles and handoffs |

Value Stream | Finds waste and improves flow |

Spaghetti Diagram | Optimizes physical movement |

Current/Future State | Compares before and after improvements |

Lean Six Sigma Process Mapping gives teams the tools to see, understand, and improve their work. By choosing the right map, teams can solve problems faster and reach their goals.

Goals and Scope

Set Objectives

Setting clear objectives forms the foundation of successful Lean Six Sigma process mapping. Teams need to know what they want to achieve before they start mapping. Well-defined objectives help everyone stay focused and measure progress. Typical objectives for process mapping include:

Define what creates value for the customer.

Align improvement efforts with strategic goals.

Gather measurement data to spot inefficiencies and non-value-adding activities.

Use data to target root causes and areas for improvement.

Establish controls to sustain improvements over time.

Communicate and train stakeholders on the improved process.

Teams also aim to create a common understanding of the process among all members. This shared view helps align perspectives and ensures everyone works toward the same goals. By listing and ordering all steps, teams can reflect the actual workflow and identify where waste or complexity exists. Teams often use standardized symbols to make the map easy to understand for everyone, including those outside the project team.

Tip: Setting priorities based on data and strategic alignment helps teams focus on the most important improvements first.

Define Boundaries

Defining boundaries means deciding where the process starts and ends. Clear boundaries prevent confusion and keep the mapping effort manageable. Teams should specify which steps, departments, or functions the map will include. This focus helps avoid unnecessary details and keeps the project on track.

A well-defined scope includes:

The starting point of the process.

The ending point of the process.

Key inputs and outputs for each step.

The roles or teams involved.

When teams document these boundaries, they make the process understandable to all stakeholders. This clarity supports better communication and helps everyone know their responsibilities.

Note: Teams should use process mapping techniques like SIPOC or flowcharts to visualize boundaries and ensure nothing important gets missed.

Avoid Scope Creep

Scope creep happens when a project grows beyond its original goals. This can lead to wasted time, confusion, and missed deadlines. Teams can prevent scope creep by outlining a clear scope of work with specific inclusions and exclusions. Regular monitoring keeps the project focused.

Recommended strategies include:

Regularly review the project charter to stay aligned with objectives.

Implement a formal change control process for any proposed changes.

Educate stakeholders about the importance of sticking to the agreed scope.

Document out-of-scope requests for future consideration.

Use the DMAIC framework to maintain structure and direction.

Teams should communicate the scope to all stakeholders and reinforce it throughout the project. By doing so, they ensure that everyone understands the limits and stays focused on the main goals.

Tip: Regular check-ins and open communication help teams catch and address scope changes early, keeping the process mapping effort efficient and effective.

Mapping Techniques

SIPOC

SIPOC diagrams give teams a high-level view of a process by breaking it into five key parts: Suppliers, Inputs, Process, Outputs, and Customers. This tool helps teams see who provides materials or data, what goes into the process, the steps involved, what comes out, and who receives the results. Teams often use SIPOC diagrams at the start of a Lean Six Sigma project, especially during the Define phase of DMAIC.

SIPOC diagrams make business processes easy to explain, even to people who are new to the process.

They help teams stay aligned by framing discussions and focusing on the right problems.

The diagrams clarify important details, such as supplier contacts, project requirements, and customer needs.

Teams use SIPOC to answer questions about process simplicity, product quality, supplier management, and customer demographics.

This tool supports process understanding and improvement, even outside formal Six Sigma projects.

By using SIPOC diagrams, teams ensure they do not miss any critical elements. The diagrams help pinpoint bottlenecks or inefficiencies early. For example, in software development, a SIPOC diagram might list project managers and developers as suppliers, requirements as inputs, coding and testing as process steps, the final application as the output, and users as customers. This approach keeps everyone informed and aligned, making it easier to improve the process.

Tip: SIPOC diagrams often lead to measurable improvements, such as reducing waste by 30% and cutting customer complaints by 25%.

Value Stream Map

Value Stream Mapping (VSM) gives teams a visual way to see every step in a process, from start to finish. This map shows both value-adding and non-value-adding activities. By including details like cycle time and wait time, VSM helps teams spot where waste builds up, such as long delays or extra steps.

Teams use VSM to find bottlenecks and unnecessary actions. The map highlights types of waste, including overproduction, waiting, defects, and excess inventory. By drawing a current state map, teams can see where problems exist. They then design a future state map to show how the process should look after improvements. This method fits well with the DMAIC framework, especially in the Analyze and Improve phases.

Value Stream Mapping supports data-driven decisions. Teams use it to focus on the biggest problems first, making improvements that have the most impact. The clear visual layout makes it easier for everyone to understand the process and work together to remove waste.

Swimlane

Swimlane diagrams help teams map processes that cross different departments or roles. Each "lane" represents a team, department, or individual. This layout makes it clear who is responsible for each step and when handoffs occur.

Swimlane diagrams improve clarity and accountability by showing responsibilities.

They boost cross-functional communication by making interactions and handoffs visible.

Teams can quickly spot inefficiencies, such as bottlenecks, redundancies, or unnecessary handoffs.

The diagrams help manage resources and timelines by providing a clear workflow.

Swimlane diagrams support standardization, making processes consistent across the organization.

Their visual nature makes it easier to find and fix problems.

Companies like Motorola, 3M, Dell, and HP have used swimlane diagrams to improve teamwork and process flow. The diagrams work well in many industries and help teams collaborate more effectively.

Note: Swimlane diagrams make it simple to identify where a process slows down or breaks, leading to faster improvements.

Thought Process Map

A Thought Process Map (TMAP) gives teams a structured way to organize their thinking at the start of a Lean Six Sigma project. This tool helps teams lay out questions, ideas, and possible issues before diving into detailed mapping or data collection. By using a TMAP, teams can see the big picture and make sure they do not miss important details.

A Thought Process Map works best in several scenarios:

Teams use TMAPs at the very beginning of Lean Six Sigma projects to build a strong foundation.

They help teams visualize the entire project before any work begins.

TMAPs allow teams to list all possible questions and issues, making sure nothing gets overlooked.

Teams use them to define project goals, identify what they know and do not know, and ask key questions related to the DMAIC phases.

TMAPs help teams decide which Lean Six Sigma tools to use and in what order.

They support brainstorming, information gathering, and data summarization.

Teams use TMAPs to track the development of ideas and issues as the project moves forward.

They are especially helpful for projects with complex processes and many connections.

TMAPs provide a visual guide that keeps the project on track from start to finish.

A typical Thought Process Map starts with the main project goal in the center. Branches extend out to show questions, known facts, unknowns, and possible challenges. Teams can add more branches as they brainstorm or gather new information. This flexible structure makes it easy to update the map as the project evolves.

Tip: Teams should revisit the Thought Process Map during each DMAIC phase. This helps them stay focused and adjust their approach as new information appears.

Thought Process Maps also improve communication. When everyone sees the same map, team members can share ideas and concerns more easily. This shared understanding helps teams avoid confusion and work together more effectively.

Many organizations use TMAPs to guide projects with many moving parts. For example, in a manufacturing project with several departments involved, a TMAP helps everyone see how their work connects. The map shows where questions remain and where more data is needed.

Team and Stakeholders

Identify Participants

Selecting the right participants shapes the success of Lean Six Sigma process mapping. Teams often start by using the SIPOC tool to identify internal suppliers, customers, and stakeholders who have direct involvement or insight into the process. The most effective teams include people who know the detailed steps, not just managers or process owners. Subject matter experts (SMEs) play a key role because they can validate and support the accuracy of the process map.

A well-chosen team brings a 360-degree view of the process. The following criteria help teams identify key participants:

Select individuals with detailed knowledge of the process steps.

Include SMEs who can stand behind the process map.

Ensure participants have the motivation, time, and energy to contribute.

Choose people with strong relationships across groups to support collaboration.

Engage sponsors early to secure critical resources and support.

Address potential conflicts by assessing readiness and managing behaviors before sessions.

Before mapping sessions, sponsors or process owners should answer questions such as:

Do you support this initiative?

Are there concerns about this effort?

Do SMEs have the time and motivation to participate?

Are relationships with external groups strong enough for teamwork?

Tip: Confirm that the right people are present, especially those who handle the process daily.

Engage Stakeholders

Stakeholder engagement ensures that process mapping reflects real needs and gains broad support. Teams measure engagement by maintaining accurate stakeholder maps. These maps identify, classify, and validate all stakeholders. Regular updates keep the maps current as roles and project conditions change.

To improve engagement, teams can:

Integrate stakeholder mapping with strategic planning and risk management.

Create channels for stakeholder feedback on roles and engagement preferences.

Use technology tools for real-time updates and collaboration.

Allocate time and training for high-quality stakeholder mapping.

Implement audits and validation sessions to maintain map integrity.

Address challenges like information gaps or misclassification by using structured protocols.

Note: Keeping stakeholder information current and validated helps teams align engagement with project goals.

Collaboration

Collaboration drives effective process mapping. Teams that foster open communication and respect diverse viewpoints achieve better results. Constructive conflict resolution helps maintain positive dynamics. Team building exercises build trust and rapport among members.

Successful teams use several collaborative techniques:

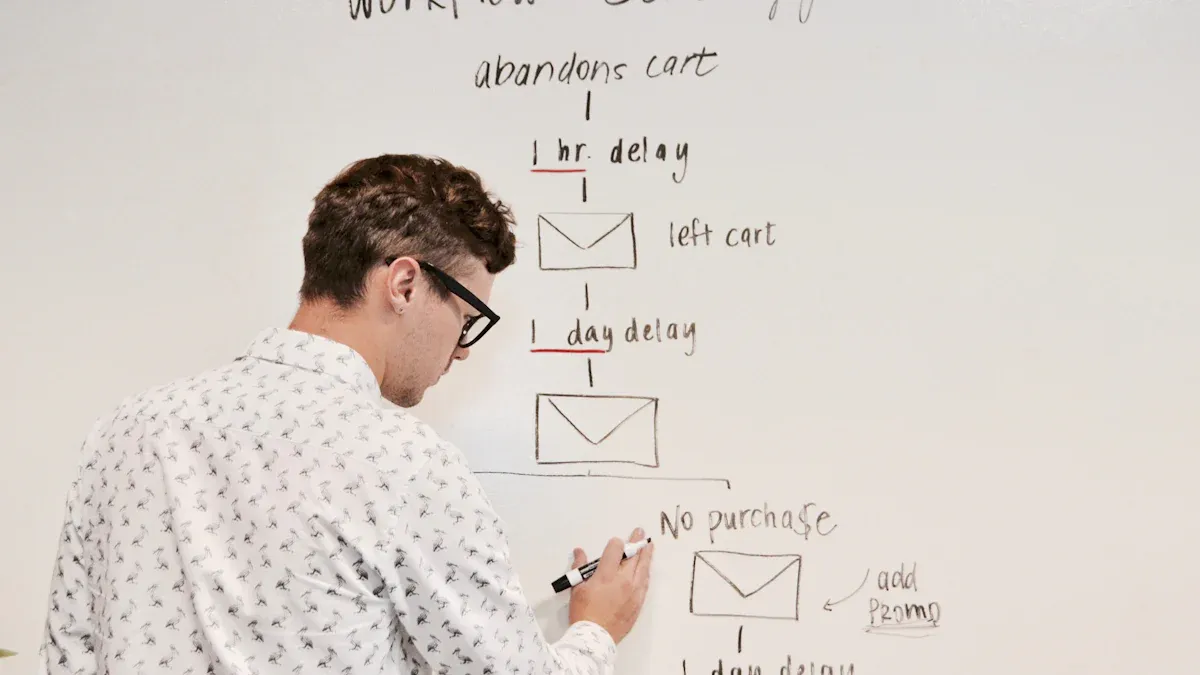

Employ visual management tools, such as whiteboards and process maps, to align understanding.

Rotate responsibilities to encourage shared ownership.

Hold frequent updates and retrospectives for alignment and improvement.

Celebrate small wins to keep motivation high.

Form cross-functional teams with operators, engineers, quality experts, maintenance, logistics, customer service, and suppliers.

Clearly define roles like team leader, SMEs, process owner, data analysts, and Lean coaches.

Use brainstorming and Failure Modes and Effects Analysis (FMEA) for idea generation and risk prioritization.

Pilot test improvements to validate changes and gather feedback.

Document responsibilities with control plans and standard work.

Tip: Visual tools and regular team check-ins help everyone stay on the same page and support continuous improvement.

Data Collection

Gather Data

Accurate data collection forms the backbone of effective Lean Six Sigma process mapping. Teams start by identifying what information they need and where to find it. They often use SIPOC diagrams to clarify suppliers, inputs, processes, outputs, and customers. This step helps teams focus on the most important data.

A structured approach to data gathering includes:

Apply a critical-to-quality tree to highlight the most important output measures.

Identify available data and determine what is still needed.

Decide if the data is continuous (like time or weight) or discrete (like counts).

Select the right forms and tools for collecting and visualizing data.

Plan how much data is necessary to spot trends and patterns.

Define how to measure each item, including clear definitions and target values.

Check if measurement systems are consistent by using gauge repeatability and reproducibility studies.

Choose between sampling and full data collection, using methods like random or stratified sampling to avoid bias.

Plan how to display and analyze the data for decision-making.

Tip: Teams improve accuracy by combining methods such as time-motion studies, surveys, and automated systems. They also use check sheets and visual controls to catch errors early.

Gemba Walk

A Gemba walk means visiting the actual place where work happens. Teams observe the process firsthand, which helps them see real issues and gather facts that data alone might miss. Leaders and team members prepare by setting clear goals and creating observation forms.

During a Gemba walk, teams:

Visit the work area to watch the process in action.

Interview employees to get their insights and feedback.

Record observations using prepared checklists or digital tools.

Share findings in meetings to validate and enrich the collected data.

Gemba walks reveal hidden problems, such as bottlenecks or waste, that may not show up in reports. By engaging frontline workers, teams gain valuable qualitative information. This direct approach leads to more accurate and actionable process maps.

Note: Gemba walks also build trust and encourage open communication between teams and employees.

Document Observations

Documenting observations ensures that process maps reflect reality, not just theory. Teams use several tools to capture what they see and hear:

Process flowcharts show each step, who does it, and when it happens.

Swimlane diagrams highlight how different teams interact and where handoffs occur.

Value stream maps focus on value-adding steps and help spot waste.

High-level process maps give an overview of the entire workflow.

To document observations well, teams:

Collect data through direct observation and interviews.

Record all relevant details, such as equipment, inputs, and outputs.

Use brainstorming with operators and managers to verify information.

Interview team members in the order of the process map, explaining the purpose.

Document tasks, roles, decisions, and connections to other processes.

Map the process as it actually works, not as it should work.

Note key activities, decisions, bottlenecks, and sources of waste.

Assign the right symbols and review the map for accuracy.

Visual documentation supports training, change management, and ongoing improvement. Teams that keep thorough records can track progress and make better decisions in the future.

Mapping Session

Preparation

Effective preparation sets the stage for a successful Lean Six Sigma Process Mapping session. Teams begin by defining the scope of the process data they want to capture. This step helps avoid collecting unnecessary information that could slow down analysis. Setting a clear time frame for the event and each session ensures the team stays on track and covers the planned scope.

A well-prepared team compiles a participant list that includes subject-matter experts, people who understand process connections, and even some who are unfamiliar with the process. This mix encourages fresh perspectives and thorough discussion. Invitations should limit face-to-face sessions to fewer than ten people, ideally with one person representing each department or division. Smaller groups help maintain focus and efficiency.

During preparation, teams avoid creating the actual process map. Instead, they focus on gathering information and exploring the process. Facilitation skills play a key role at this stage. Tools like SIPOC diagrams help teams gain a high-level understanding before diving into details.

Tip: Preparation is not about mapping the process yet. It is about setting clear goals, gathering the right people, and making sure everyone understands the session’s purpose.

Preparation Checklist:

Define the process scope and data to capture.

Set a strict time frame for the session.

Select participants with diverse knowledge.

Limit group size for efficiency.

Gather background information using tools like SIPOC.

Focus on exploration, not mapping.

Execution

During the mapping session, strong facilitation ensures the team stays productive and focused. The facilitator leads discussions, manages conflicts, and encourages everyone to share their knowledge. Keeping conversations on topic prevents scope creep and helps the team achieve its goals.

Teams start by documenting the current "As Is" process. They avoid jumping to solutions or mapping how the process should work. This approach ensures the map reflects reality, not assumptions. The facilitator recognizes that participants may have different levels of understanding. By managing these differences, the team maintains focus and productivity.

The session uses visual tools such as whiteboards or digital platforms. These tools help everyone see the process as it unfolds. The facilitator asks clear questions like, "What happens next?" and "Where does this break down?" This method uncovers important details and keeps the session moving forward.

Note: Teams should resist the urge to solve problems during mapping. The goal is to capture the current process accurately before moving to improvements.

Facilitation Techniques:

Keep the team focused on session goals.

Document the current process, not the ideal.

Use visual tools for clarity.

Ask simple, direct questions.

Manage different understanding levels among participants.

Capture Exceptions

Capturing exceptions and process variations is a critical part of Lean Six Sigma Process Mapping. Teams engage the right stakeholders early because they know where gaps and exceptions exist. The mapping session begins with high-level steps and then drills down into details.

Facilitators encourage participants to share not only the standard process but also any variations or exceptions. They ask questions such as, "Where does this process break down?" and "What happens when things do not go as planned?" Teams use visual tools to make exceptions visible to everyone.

After mapping, the team validates the process map with participants. This step ensures accuracy and helps identify any missed exceptions. Teams document both the "happy path" and all known variations. They may use digital tools to associate specific exception handling maps with the main process.

Tip: Always document exceptions and variations as part of the process. This practice helps teams prepare for real-world challenges and supports continuous improvement.

Steps to Capture Exceptions:

Involve stakeholders who know the process well.

Start with high-level mapping, then add details.

Ask clear questions about breakdowns and variations.

Use visual tools to display exceptions.

Validate the map with participants.

Document both standard and exception paths.

Common Pitfall:

Teams sometimes overlook exceptions by focusing only on the standard process. This mistake can lead to incomplete maps and missed improvement opportunities.

Improvement Ideas

Generating improvement ideas forms a key part of any process mapping session. Teams use this stage to turn observations into practical changes. They look for ways to remove waste, reduce errors, and make work flow better. The best sessions encourage everyone to share ideas, no matter their role or experience.

How Teams Generate Improvement Ideas:

Ask Open-Ended Questions:

Teams start by asking questions like, "What slows down this step?" or "Where do mistakes happen most often?" These questions help uncover hidden problems and spark creative thinking.Use Visual Tools:

Teams often use sticky notes, whiteboards, or digital mapping tools. These visuals make it easy to move steps around and try new ideas. Seeing the process helps people spot gaps or extra steps.Encourage All Voices:

Every team member brings a unique view. Operators, managers, and support staff all see different parts of the process. Teams get better ideas when everyone feels safe to speak up.Focus on Value:

Teams check each step to see if it adds value for the customer. Steps that do not add value become targets for removal or change.Brainstorm Solutions:

Teams set aside time to brainstorm. They list as many ideas as possible before judging them. This approach leads to more creative solutions.Prioritize Changes:

Not all ideas can be done at once. Teams use simple tools like impact-effort grids to pick the best ideas to try first.

Tip: Teams should revisit the process map after making changes. This helps them see if the improvements worked and find new areas to fix.

Common Pitfalls and How to Avoid Them:

Teams sometimes face challenges when trying to generate improvement ideas. Some common pitfalls include:

Unengaged or distracted team members, especially managers.

Unclear or misunderstood problem statements.

Lack of agreement on what value the process should deliver.

Poor facilitation that leads to off-topic discussions, sometimes called "rabbit holes."

Mapping the process at the wrong level of detail.

Spending too much time on small details and losing focus.

Teams can avoid these pitfalls by:

Securing commitment from the process owner to keep everyone engaged.

Clearly defining and agreeing on the problem statement before starting.

Creating a shared value statement to guide decisions.

Using strong facilitation techniques, such as involving everyone in writing process steps and using a "Car Park" to park off-topic issues for later.

Mapping the process at the right level of detail and limiting the number of steps to stay efficient.

Real-World Example:

A hospital team mapped the patient check-in process. They noticed long wait times and many repeated questions. By brainstorming together, they decided to combine forms and train staff to handle multiple steps at once. After making these changes, patient wait times dropped by 40%, and staff felt less stressed.

Note: Teams should celebrate small wins. Even simple changes, like moving a supply cart closer to where it is needed, can save time and boost morale.

Table: Quick Checklist for Generating Improvement Ideas

Step | What to Do |

|---|---|

Ask open questions | Find pain points and bottlenecks |

Use visual tools | Make ideas easy to see and change |

Involve everyone | Get input from all roles |

Focus on value | Remove or change non-value steps |

Brainstorm solutions | List many ideas before choosing |

Prioritize improvements | Pick changes with the biggest impact |

Analyze for Waste

Identify Bottlenecks

Teams use several techniques to spot bottlenecks in Lean Six Sigma process maps. Bottlenecks slow down work and create delays. Value Stream Mapping helps visualize the flow of materials and information. This tool shows where work piles up or moves slowly. Process Cycle Time Analysis measures how long each step takes. Steps that use too much time or resources often signal a bottleneck. Takt Time Calculations compare how fast a process runs to customer demand. If actual cycle times fall behind, a bottleneck may exist.

Gemba Walks allow team members to observe work directly. They see problems that data might miss. Root Cause Analysis tools, such as the 5 Whys and Fishbone Diagrams, help teams ask questions and find the main cause of slowdowns. Data Collection and Statistical Analysis, including control charts, reveal patterns and anomalies. These methods help teams focus on the steps that need the most attention.

Tip: Teams should use both visual tools and direct observation to find bottlenecks that may not be obvious from numbers alone.

Non-Value Steps

Non-value-added steps do not help the customer or improve the product. Teams use process mapping to diagram each step and ask if it adds value. Value Stream Mapping highlights activities that waste time or resources. Examples of non-value steps include extra approvals, repeated paperwork, long waiting times, and unnecessary movement.

Teams break down the process into individual steps. They mark steps that do not meet customer needs as waste. 5S workplace organization keeps things tidy and reduces waste. Standardized work and visual management make processes clear and consistent. Mistake-proofing prevents defects before they happen. Kaizen encourages everyone to suggest ways to cut waste. Pull production systems produce only what is needed, stopping excess inventory.

Common Non-Value Steps:

Redundant approvals

Excessive waiting

Unneeded transportation

Duplicate paperwork

Teams assess the impact of these steps by measuring time, cost, and resources. They develop strategies to remove or reduce waste. Changes may include redesigning the process, updating equipment, or training staff. Continuous monitoring helps teams keep waste out and efficiency up.

Prioritize Improvements

After mapping the process and finding waste, teams must decide which improvements to tackle first. They use several criteria to rank opportunities. Alignment with business goals and strategic needs comes first. Teams look at the impact on key metrics, such as defects and cost. Ease of implementation matters. Projects with quick wins or simple changes often get priority.

Teams consider the scale of benefit. Improvements that help many people or save lots of time rise to the top. Sponsor and leadership support make projects more likely to succeed. Sustainability ensures changes last over time. Teams listen to the Voice of the Customer and the Voice of the Market. Process owner and employee involvement help make changes stick.

Priority matrices and scoring methods, like the TIM WOODS checklist, help teams rank ideas. Teams avoid projects without clear support or definition. The best improvements have strong business impact, manageable scope, and solid backing.

Prioritization Criteria | Description |

|---|---|

Strategic Alignment | Matches business goals |

Reduces defects, cost, or cycle time | |

Ease of Implementation | Simple to put in place |

Scale of Benefit | Helps many or saves much |

Sponsor Engagement | Has leadership support |

Sustainability | Lasts over time |

Customer/Market Voice | Meets real needs |

Teams should choose improvements that offer the biggest benefit and have strong support. This approach leads to lasting results and better processes.

Action Plan and Control

Develop Plan

Teams use process mapping to create a clear picture of how work happens. This visual tool helps everyone see each step, decision point, input, and output. With this baseline, teams can spot waste and plan targeted improvements. An effective action plan starts by aligning Lean Six Sigma goals with the company’s main objectives. Teams identify business needs and focus on areas with the biggest impact.

To build a strong plan, teams follow these steps:

Align improvement goals with business strategy.

Identify core business needs and key skills.

Brainstorm and prioritize projects that close performance gaps.

Match team members to projects based on their strengths.

Sequence tasks, assign resources, and set realistic timelines.

Prepare training plans and project roadmaps.

A good plan includes clear project plans, training schedules, and ways to track benefits. Teams use these tools to keep everyone focused and ensure that improvements support the company’s goals.

Tip: Teams should use process maps as a guide when choosing which projects to tackle first.

Implement Changes

After planning, teams move to action. They start by sharing the plan with everyone involved. Clear communication helps each person understand their role. Teams use visual tracking tools, such as dashboards or progress boards, to show what has been done and what comes next.

During implementation, teams:

Assign tasks and responsibilities.

Provide training and support.

Monitor progress with regular check-ins.

Adjust the plan if problems arise.

Visible tracking keeps the team motivated and accountable. Regular updates help leaders spot issues early and make quick changes. Teams also document lessons learned, which helps with future projects.

Key Outputs:

Output Type | Purpose |

|---|---|

Training Plans | Prepare staff for new processes |

Project Plans | Guide step-by-step execution |

Status Reports | Track progress and share updates |

Improvement Roadmaps | Show the path from current to future state |

Review and Sustain

Sustaining improvements means checking if changes work over time. Teams use a balanced set of metrics to track results. These include quality, time, cost, and employee engagement. For example, teams measure defect rates, cycle times, and costs linked to rework or waste. They also check if staff stay involved in improvement activities.

Some key metrics include:

First Time Yield (FTY)

Rolled Throughput Yield (RTY)

Process Capability Indices (Cp and Cpk)

Sigma Level

Cost of Poor Quality (COPQ)

Teams use real-time dashboards to watch these numbers. If a metric drops, they investigate the cause and act quickly. Regular reviews help teams keep improvements on track and spot new problems early.

Note: Teams that track both process results and employee engagement build a culture of continuous improvement. This approach keeps gains in place and supports long-term success.

Teams improve processes by following best practices. They set clear goals, define boundaries, and use the right mapping techniques. Regular reviews help teams find new areas for improvement. Process mapping reduces waste and supports better results.

Review process maps often

Share ideas with team members

Explore Lean Six Sigma training or books

Continuous learning leads to stronger process improvement skills.

FAQ

What is the main purpose of Lean Six Sigma process mapping?

Lean Six Sigma process mapping helps teams see each step in a workflow. They use maps to find waste, spot errors, and improve efficiency. This tool supports better decision-making and process improvement.

How often should teams update their process maps?

Teams should review and update process maps whenever they change a workflow or find new problems. Regular updates keep maps accurate and useful for ongoing improvement.

Which mapping technique works best for beginners?

SIPOC diagrams work well for beginners. They show the big picture and help teams understand suppliers, inputs, processes, outputs, and customers. SIPOC makes it easy to start mapping without too much detail.

Who should join a process mapping session?

Teams should include subject matter experts, process owners, and frontline staff. Each person brings unique knowledge. Diverse groups help create accurate maps and find better solutions.

What is a common mistake in process mapping?

Teams sometimes map the process as they want it to be, not as it actually works. This mistake leads to missed problems. Accurate mapping requires honest observation and input from those who do the work.

How can teams identify non-value steps?

Teams ask if each step adds value for the customer. They use value stream maps to highlight waste, such as extra approvals or waiting. Removing non-value steps improves speed and quality.

Why is stakeholder engagement important in process mapping?

Stakeholder engagement ensures the process map reflects real needs. Involving stakeholders builds support for changes and helps teams avoid missing key details.

What tools help teams track process improvements?

Teams use dashboards, check sheets, and visual boards to track progress. These tools show results, highlight issues, and keep everyone informed about changes.