Mastering the Basics of Six Sigma Process Mapping

Six Sigma process mapping serves as a powerful visual tool for understanding and improving workflows. By breaking down complex processes into manageable steps, it provides clarity and helps uncover inefficiencies. For example, Bank of America discovered that over 90% of its processes involved non-value-added activities, highlighting areas for improvement. Organizations using Six Sigma process mapping often achieve remarkable results, such as defect reductions of 70-90% and cycle time improvements of 30-50%, leading to enhanced productivity and cost savings.

This method aligns closely with the Six Sigma methodology by promoting data-driven decision-making and continuous improvement. Companies like GE Healthcare have leveraged it to achieve significant outcomes, such as a 62% reduction in manufacturing defects and annual savings of $10.2 million. By optimizing workflows, businesses can allocate resources more effectively and deliver consistent quality to clients and customers.

Key Takeaways

Six Sigma process mapping shows workflows to find and fix problems.

It can improve results, cutting defects by 70-90% and time by 30-50%.

Involving team members in mapping helps find hidden problems.

Updating maps often keeps them accurate and useful over time.

Removing useless steps makes processes faster and saves money.

Process mapping gives data to help teams choose what to fix first.

Different maps, like SIPOC and swimlane, help study workflows.

Checking and changing maps often helps meet new company goals.

What is Six Sigma Process Mapping?

Definition and Purpose

Six Sigma process mapping is a structured approach to visually representing workflows, enabling teams to identify inefficiencies and optimize processes. It breaks down complex operations into smaller, manageable steps, offering a clear picture of how tasks flow from start to finish. This tool plays a critical role in the Six Sigma methodology by helping organizations achieve near-perfect process performance.

At its core, Six Sigma process mapping focuses on reducing defects and improving quality. For instance, the concept of Defects Per Million Opportunities (DPMO) measures process performance by identifying the number of defects in a million opportunities. Another key metric, the process capability index (Cpk), evaluates how closely a process operates within its specification limits. These metrics highlight the importance of precision and consistency in achieving Six Sigma standards, which aim for only 3.4 defects per million opportunities.

Key Features of Process Mapping

Six Sigma process mapping offers several features that make it an invaluable tool for process improvement. These features include:

Improved Understanding: Visual representations of workflows help teams identify inefficiencies and waste.

Increased Efficiency: By pinpointing root causes of delays or errors, teams can streamline processes and reduce cycle times.

Enhanced Customer Satisfaction: Addressing inefficiencies leads to higher-quality products or services, fostering customer loyalty.

Cost Reduction: Eliminating waste lowers production costs and boosts profitability.

Improved Communication: Process maps create a common framework for discussions, enhancing collaboration and decision-making.

For example, a manufacturing company used process mapping to analyze production data and discovered that 70% of defects originated from a single machine. Replacing the machine reduced defects by 60%, demonstrating the tangible benefits of this approach. Similarly, organizations that implement process mapping often report a 10-30% increase in productivity and a 7% rise in customer satisfaction scores.

How Process Mapping Supports Business Goals

Six Sigma process mapping aligns closely with organizational objectives by driving efficiency, reducing costs, and enhancing customer satisfaction. It provides a clear roadmap for achieving measurable outcomes, such as:

Impact | Measurable Outcome |

|---|---|

Reduced production delays | 40% reduction in delays in supply chain |

Reduced order processing time | 30% reduction by automating confirmations |

Cut onboarding time | Reduced from 10 days to 5 days |

By streamlining operations and improving team collaboration, process mapping helps businesses achieve significant time and cost savings. For instance, healthcare systems that implemented SIPOC diagrams reported a 30% reduction in undetected dispensing errors and a 20% decrease in hospital-acquired infections. These results highlight the versatility of Six Sigma process mapping in addressing challenges across industries.

Why Six Sigma Process Mapping is Important

Enhancing Process Understanding

Six Sigma Process Mapping improves how teams understand workflows by visually representing each step. This clarity fosters better communication among stakeholders, ensuring alignment on process objectives. For example, stakeholder engagement often reveals gaps in understanding, such as misaligned expectations or unclear responsibilities. Process mapping addresses these issues by creating a shared framework that highlights inefficiencies and hidden complexities.

Teams frequently discover that enhancing their understanding of existing workflows, rather than redesigning them, leads to significant operational improvements. Discussions prompted by process mapping help clarify the necessity of each step, ensuring that every action adds value. This approach not only streamlines operations but also builds a culture of collaboration and transparency.

Identifying and Eliminating Inefficiencies

Process mapping serves as a diagnostic tool for uncovering inefficiencies that hinder productivity. By breaking down workflows into smaller components, teams can pinpoint bottlenecks, redundant tasks, and areas of waste. For instance, organizations using Six Sigma Process Mapping have reported measurable benefits, such as:

Benefit | Quantified Impact |

|---|---|

Waste Reduction | |

Cycle Time Improvement | 20% improvement |

Customer Complaints Reduction | 25% reduction |

Product Returns Decrease | 15% decrease |

These results demonstrate how process mapping drives efficiency by eliminating non-value-added activities. Teams can focus on optimizing workflows, reducing delays, and improving overall performance.

Supporting Data-Driven Decision Making

Six Sigma Process Mapping supports data-driven decision-making by providing metrics that quantify process performance. Teams can use tools like process capability indices (Cp, Cpk), defects per million opportunities (DPMO), and yield metrics to evaluate workflows. These insights enable organizations to make informed decisions about where to allocate resources and how to prioritize improvements.

For example, right-first-time rates and process sigma levels offer valuable benchmarks for assessing quality. Teams can use these metrics to identify areas that require attention and track progress over time. By leveraging data, organizations ensure that their decisions align with strategic goals and deliver measurable results.

Process mapping also fosters a culture of continuous improvement. Teams regularly update maps to reflect changes, ensuring that workflows remain efficient and aligned with organizational objectives. This iterative approach helps businesses adapt to evolving challenges and maintain a competitive edge.

Six Sigma Process Mapping and the DMAIC Framework

The DMAIC framework—Define, Measure, Analyze, Improve, and Control—serves as the backbone of Six Sigma methodology. Six Sigma Process Mapping integrates seamlessly into this framework, providing a structured approach to process improvement. Each phase of DMAIC leverages process mapping to achieve specific objectives, ensuring that workflows are optimized and aligned with organizational goals.

Define Phase: Setting the Foundation

The Define phase establishes the groundwork for process improvement. Teams identify the problem, set objectives, and outline the scope of the project. Process mapping plays a crucial role in this phase by visually representing the current state of workflows. This helps teams understand how processes function and where inefficiencies may exist.

For example, a SIPOC (Suppliers, Inputs, Process, Outputs, Customers) diagram is often used during this phase. It provides a high-level overview of the process, highlighting key elements such as inputs and outputs. This clarity ensures that all stakeholders have a shared understanding of the process and its objectives. By setting a strong foundation, the Define phase ensures that subsequent steps in the DMAIC framework are focused and effective.

Measure Phase: Collecting Data for Mapping

The Measure phase focuses on gathering accurate data to understand the current state of the process. Reliable data collection is essential for creating an effective process map. Statistical methods are often applied during this phase to ensure the validity and reliability of the data. These methods include:

Statistical Method | Purpose |

|---|---|

Hypothesis Testing | To determine if there are significant differences between process variables. |

Correlation Analysis | To identify relationships between different process variables. |

Regression Analysis | To model the relationship between a dependent variable and one or more independent variables. |

These techniques help teams make data-driven decisions and identify subtle changes in processes that may indicate larger issues. For instance, correlation analysis can reveal how one variable impacts another, providing insights into potential bottlenecks. By ensuring that measurements are reliable, the Measure phase sets the stage for meaningful analysis and improvement.

Statistical analysis also supports the identification of inefficiencies. Teams can use this data to validate their conclusions and ensure that process maps accurately reflect real-world conditions. This approach minimizes errors and enhances the overall effectiveness of the Six Sigma Process Mapping initiative.

Analyze Phase: Identifying Process Gaps

The Analyze phase uses the data collected in the previous step to identify gaps and inefficiencies in the process. Process mapping becomes a diagnostic tool during this phase, helping teams visualize where problems occur. By breaking down workflows into smaller components, teams can pinpoint root causes of delays, errors, or waste.

For example, a swimlane diagram can be used to analyze responsibilities across different departments. This type of process map highlights handoffs and interactions, making it easier to identify areas where communication breaks down. Teams can then focus on addressing these issues to streamline workflows and improve efficiency.

Data analysis further enhances the effectiveness of this phase. Metrics such as defects per million opportunities (DPMO) and process capability indices (Cpk) provide quantitative insights into process performance. These metrics help teams prioritize areas for improvement, ensuring that resources are allocated effectively. By identifying and addressing process gaps, the Analyze phase lays the groundwork for designing better workflows in the Improve phase.

Improve Phase: Designing Better Processes

The Improve Phase focuses on implementing solutions to address the root causes of inefficiencies identified in earlier stages. Teams use insights from the Analyze Phase to design and test process improvements. This phase emphasizes creating actionable strategies that lead to measurable outcomes.

Key activities in this phase include:

Identifying and prioritizing solutions that eliminate root causes.

Monitoring progress to ensure improvements align with organizational goals.

For example, a manufacturing team might redesign a workflow to reduce production delays. By streamlining handoffs between departments, they can eliminate bottlenecks and improve cycle times. Similarly, a service-based organization might automate repetitive tasks, freeing up resources for higher-value activities.

Teams also collect data during this phase to evaluate the effectiveness of their changes. Metrics such as defect rates, cycle times, and customer satisfaction scores provide valuable feedback. These measurements help determine whether the improvements achieve the desired results.

Tip: Continuous monitoring during the Improve Phase ensures that implemented changes deliver long-term benefits. Teams should remain flexible and ready to adjust their strategies based on real-time data.

Control Phase: Sustaining Improvements

The Control Phase ensures that the improvements made during the Improve Phase are maintained over time. This phase focuses on monitoring process stability and preventing regression to previous inefficiencies.

Control charts play a critical role in this phase. These tools track process performance over time, helping teams identify variations. For instance, I-MR charts and P charts monitor specific parameters, such as defect rates or production times. By defining control limits, these charts distinguish between normal variations and abnormalities that require corrective action.

Sustaining improvements also involves standardizing processes. Teams document new workflows and train employees to follow updated procedures. This ensures consistency and minimizes the risk of errors. For example, a healthcare organization might implement checklists to reduce medication errors, ensuring that staff adhere to best practices.

Regular audits and reviews further support process stability. Teams periodically assess workflows to confirm that improvements remain effective. This proactive approach helps organizations adapt to changing conditions while maintaining high performance levels.

Note: A culture of accountability is essential for sustaining improvements. Encouraging employees to take ownership of their roles fosters long-term success in process optimization.

Benefits of Six Sigma Process Mapping

Improved Communication and Collaboration

Six Sigma Process Mapping enhances communication by creating a shared understanding of workflows. Teams use visual tools to represent processes, which simplifies complex operations and ensures that everyone interprets them consistently. This clarity fosters collaboration among stakeholders, as it eliminates misunderstandings and aligns efforts toward common goals.

For example, in software development, transparency in the Software Requirements Specifications (SRS) positively impacts communication and productivity. Object-oriented SRS documents are easier to maintain, which improves stakeholder interactions and boosts efficiency. Similarly, process mapping provides a framework for discussions, enabling teams to identify inefficiencies and propose solutions collaboratively.

Organizations often report increased productivity when communication improves. Teams work more cohesively, reducing delays caused by miscommunication. By fostering collaboration, process mapping builds stronger relationships among departments and ensures that workflows run smoothly.

Enhanced Transparency and Accountability

Transparency is a cornerstone of Six Sigma Process Mapping. By visually representing workflows, teams gain a clear view of each step and its associated responsibilities. This visibility ensures that everyone understands their role, promoting accountability and reducing errors.

In industries like healthcare, transparency has led to measurable improvements. For instance, hospitals using process maps have reduced medication errors by standardizing procedures and clarifying responsibilities. Similarly, in manufacturing, process mapping highlights inefficiencies, enabling teams to address them proactively.

Transparency also strengthens stakeholder trust. When processes are clear and well-documented, stakeholders feel confident in the organization's ability to deliver consistent results. This trust fosters a culture of accountability, where employees take ownership of their tasks and strive for excellence.

Streamlined Workflows and Reduced Waste

Six Sigma Process Mapping streamlines workflows by identifying and eliminating non-value-added activities. Teams analyze each step to determine its necessity, focusing on optimizing processes and reducing waste. This approach improves efficiency and lowers costs, benefiting both the organization and its customers.

For example, a manufacturing company used process mapping to identify redundant steps in its production line. By removing these steps, the company reduced cycle times and minimized material waste. Similar results have been observed in service industries, where process mapping has streamlined operations and improved customer satisfaction.

Reducing waste also aligns with sustainability goals. Organizations that optimize workflows consume fewer resources, contributing to environmental conservation. This dual benefit—enhanced efficiency and reduced environmental impact—makes process mapping a valuable tool for modern businesses.

Better Alignment with Organizational Goals

Six Sigma process mapping helps organizations align workflows with their strategic objectives. By visually representing processes, teams can identify gaps between current operations and desired outcomes. This alignment ensures that every activity contributes to the organization's mission and goals.

Key Ways Process Mapping Supports Alignment

Clarifying Objectives

Process mapping provides a clear view of how workflows connect to organizational goals. Teams can evaluate whether each step adds value or supports the broader mission. For example, a retail company might use a SIPOC diagram to ensure its supply chain processes align with customer satisfaction goals.Prioritizing Resources

Visual tools help teams allocate resources effectively. By identifying bottlenecks or redundant tasks, organizations can focus efforts on high-impact areas. For instance, a healthcare provider might streamline patient intake processes to reduce wait times, aligning with its goal of improving patient care.Tracking Progress

Process maps serve as benchmarks for measuring success. Teams can compare current workflows to the ideal state and monitor improvements over time. Metrics such as cycle times and defect rates provide tangible evidence of progress toward organizational objectives.

Benefits of Alignment

Benefit | Impact |

|---|---|

Increased Efficiency | Faster workflows and reduced delays |

Enhanced Customer Satisfaction | Improved service quality and reliability |

Higher Profitability | Lower costs and optimized resource usage |

Tip: Regularly updating process maps ensures workflows remain aligned with evolving organizational goals.

Real-World Example

A logistics company used Six Sigma process mapping to align its delivery operations with its goal of reducing shipping times. By analyzing workflows, the team identified inefficiencies in route planning. Implementing changes reduced delivery times by 25%, boosting customer satisfaction and achieving a key organizational objective.

Six Sigma process mapping fosters a culture of accountability and continuous improvement. Teams gain a deeper understanding of how their actions impact the organization’s success. This alignment not only drives operational excellence but also ensures long-term sustainability.

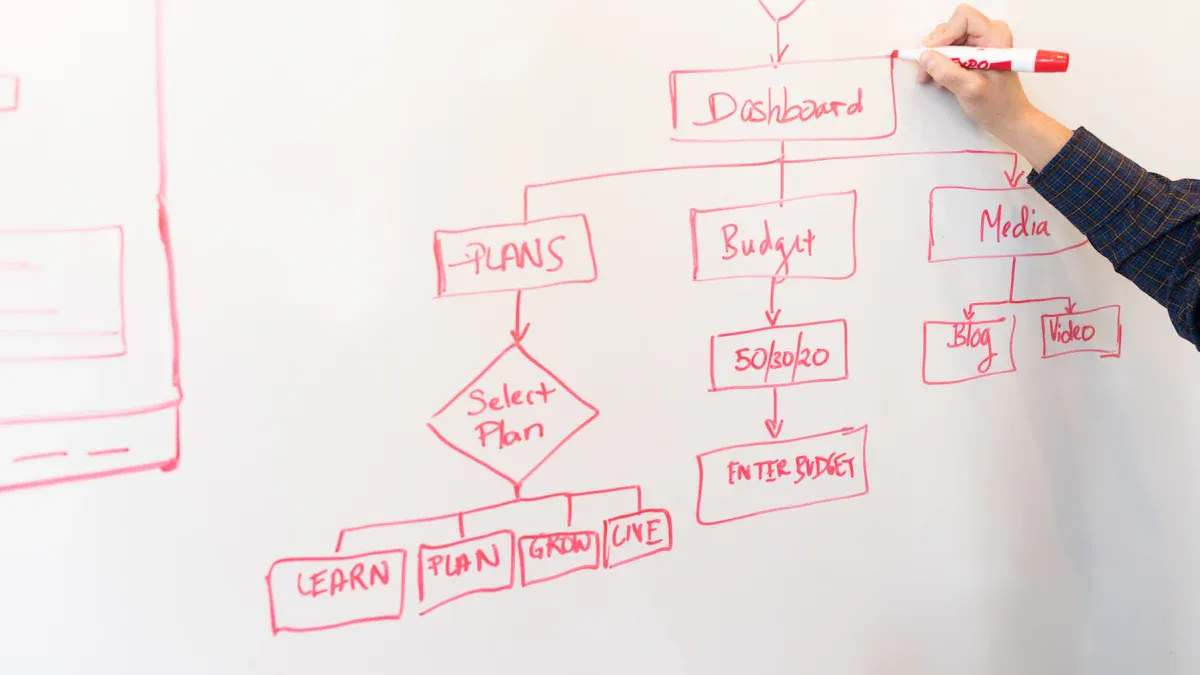

Types of Six Sigma Process Maps

Six Sigma process maps come in various forms, each tailored to specific needs and objectives. These tools provide visual clarity, enabling teams to analyze workflows, identify inefficiencies, and implement improvements. Below are three commonly used types of process maps.

SIPOC Diagram

The SIPOC diagram offers a high-level overview of a process by breaking it into five key components: Suppliers, Inputs, Process, Outputs, and Customers. This type of map is particularly effective during the Define phase of the DMAIC framework. It helps teams understand the scope of a process and its critical elements.

For example, a manufacturing company might use a SIPOC diagram to analyze its supply chain. By identifying suppliers and inputs, the team can pinpoint delays or quality issues. Similarly, in healthcare, SIPOC diagrams have been used to streamline patient intake processes, reducing wait times by 20%. This tool ensures that all stakeholders have a shared understanding of the process, fostering alignment and collaboration.

Tip: SIPOC diagrams are ideal for projects requiring a clear definition of process boundaries and key contributors.

High-Level Process Map

A high-level process map provides a simplified view of a workflow, focusing on major steps rather than intricate details. This type of map is useful for identifying bottlenecks and redundancies in complex operations. It allows teams to visualize the entire process and prioritize areas for improvement.

For instance, a retail company used a high-level process map to analyze its order fulfillment system. The map revealed that manual data entry caused delays, prompting the team to automate this step. As a result, order processing time decreased by 30%. High-level maps are also valuable for guiding change management, as they offer a clear picture of current workflows and potential improvements.

Key benefits of high-level process maps include:

Simplifying complex workflows for better understanding.

Highlighting inefficiencies and opportunities for optimization.

Serving as a foundation for more detailed analysis.

Swimlane Diagram

The swimlane diagram organizes processes by roles or departments, making it easier to identify handoffs and responsibilities. Each "lane" represents a specific team or individual, ensuring accountability and clarity. This type of map is particularly effective for cross-functional processes involving multiple stakeholders.

For example, a software development team used a swimlane diagram to analyze its product release cycle. The map highlighted delays during the testing phase, caused by unclear handoffs between developers and quality assurance teams. By addressing these gaps, the team reduced release times by 25%. Swimlane diagrams also enhance collaboration by visually illustrating how different roles interact within a process.

Type of Process Map | Effectiveness |

|---|---|

Process Flowchart | Provides a visual model of the sequence of activities and decision points, aiding in understanding. |

SIPOC Map | Breaks down key elements into Suppliers, Inputs, Process, Outputs, and Customers for clarity. |

Deployment Flowchart | Illustrates roles and responsibilities, enhancing team collaboration and accountability. |

Note: Swimlane diagrams are particularly useful for identifying inefficiencies in processes with frequent handoffs or shared responsibilities.

Each type of process map serves a unique purpose, helping organizations visualize workflows, identify inefficiencies, and drive improvements. By selecting the right tool for the task, teams can achieve greater efficiency and alignment with organizational goals.

Value Stream Map

A Value Stream Map (VSM) provides a comprehensive view of the entire process, from start to finish, by mapping out every step involved in delivering a product or service. This tool focuses on identifying value-added and non-value-added activities, making it a cornerstone of Lean Six Sigma practices. Teams use VSMs to pinpoint inefficiencies, reduce waste, and optimize workflows.

The VSM includes key elements such as process steps, material flow, information flow, and cycle times. For example, a manufacturing company might use a VSM to analyze its production line. The map could reveal that excessive inventory between two steps causes delays. By addressing this issue, the company could reduce lead times and improve efficiency.

Key Benefits of Value Stream Mapping:

Waste Reduction: Identifies unnecessary steps that do not add value.

Improved Flow: Highlights bottlenecks and delays in the process.

Enhanced Decision-Making: Provides a clear visual representation for better analysis.

Tip: When creating a VSM, involve team members from all relevant departments. Their insights can help uncover hidden inefficiencies.

Value Stream Maps are particularly effective in industries like manufacturing, healthcare, and logistics. For instance, a hospital might use a VSM to streamline patient discharge processes, reducing wait times by 15%. This tool ensures that every step in the workflow contributes to delivering value to the customer.

Detailed Process Flowchart

A Detailed Process Flowchart provides an in-depth look at a specific process by breaking it down into individual steps. Unlike high-level maps, this tool focuses on granular details, making it ideal for identifying root causes of inefficiencies. Teams use symbols such as ovals, rectangles, and diamonds to represent start points, tasks, and decision points.

For example, a software development team might create a detailed flowchart to map out its bug-fixing process. The chart could reveal that unclear communication between developers and testers causes delays. By addressing this issue, the team could improve turnaround times and enhance product quality.

Common Uses of Detailed Process Flowcharts:

Root Cause Analysis: Identifies specific steps where errors occur.

Training and Onboarding: Provides clear instructions for new employees.

Process Standardization: Ensures consistency across teams and departments.

Symbol | Meaning |

|---|---|

Oval | Start or end of a process |

Rectangle | Task or activity |

Diamond | Decision point |

Note: Use software tools like Microsoft Visio or Lucidchart to create detailed flowcharts. These tools simplify the process and ensure accuracy.

Detailed Process Flowcharts are versatile and applicable across various industries. For instance, a retail company might use one to optimize its inventory management system. By visualizing each step, the company could reduce stockouts and improve customer satisfaction. This tool empowers teams to dive deep into processes and implement targeted improvements.

How to Create a Six Sigma Process Map

Step 1: Define the Process Scope and Objectives

Defining the scope and objectives is the first step in creating an effective Six Sigma process map. Teams must establish clear boundaries for the process and identify what they aim to achieve. This step ensures that efforts remain focused and aligned with organizational goals.

To begin, teams should:

Define the project goal(s) to clarify the purpose of the process map.

List knowns and unknowns to identify areas requiring further investigation.

Ask relevant questions based on the DMAIC framework, such as "What are the key inputs and outputs?" and "Where do inefficiencies occur?"

Sequence and link these questions logically to guide the mapping process.

Identify tools, such as SIPOC diagrams or swimlane charts, that will best represent the process.

For example, a manufacturing team might set a goal to reduce production defects by 20%. By defining the scope, they can focus on specific stages of the production line rather than attempting to map the entire operation. This targeted approach saves time and ensures actionable insights.

Tip: Use large easel pads or poster boards during brainstorming sessions to make the process visible to all team members. Incorporating Post-its and colored markers can also help organize information effectively.

Step 2: Gather Data and Inputs

Accurate data collection is critical for creating a reliable process map. Teams must gather inputs from all relevant stakeholders to ensure a comprehensive understanding of the workflow. This step involves identifying key activities, resources, and decision points within the process.

Best practices for data gathering include:

Involving the entire team to capture diverse perspectives.

Avoiding critique during initial discussions to encourage open sharing of ideas.

Listing unknowns for further research rather than making assumptions.

Teams should also monitor success indicators during this phase. These include:

Indicator | Description |

|---|---|

Measurable reduction in defects or errors, tracked using tools like Pareto charts and control charts. | |

Process efficiency gains | Streamlining workflows and reducing cycle times, assessed through metrics like throughput and first-pass yield. |

Cost savings | Reduction in operational costs due to fewer defects and inefficiencies, calculated from waste reduction and improved resource utilization. |

Customer satisfaction | Monitoring customer satisfaction scores (CSAT) and net promoter scores (NPS) to gauge the impact on customer needs. |

Employee engagement | Increased participation in improvement projects and positive feedback from teams indicating cultural adoption of Six Sigma. |

For instance, a healthcare system might collect data on patient wait times and staff handoffs to identify bottlenecks in its admission process. This information forms the foundation for creating an accurate and actionable process map.

Step 3: Select the Appropriate Process Map Type

Choosing the right type of process map depends on the complexity and purpose of the workflow being analyzed. Each map type offers unique benefits, making it essential to match the tool to the specific needs of the project.

Key considerations when selecting a process map include:

The level of detail required.

The number of stakeholders involved.

The type of inefficiencies being addressed.

For high-level overviews, SIPOC diagrams work well. They provide a broad understanding of suppliers, inputs, processes, outputs, and customers. For more detailed analysis, swimlane diagrams or value stream maps can highlight inefficiencies and handoffs between departments. Teams should also ensure they use correct symbols for activities, decisions, and endpoints to maintain clarity.

Note: Always check the completeness of the process map before proceeding. Missing steps or unclear connections can lead to inaccurate conclusions.

By selecting the appropriate map type, teams can visualize workflows effectively and identify opportunities for improvement. This step ensures that the process map serves as a practical tool for achieving Six Sigma objectives.

Step 4: Map the Current State

Mapping the current state involves creating a visual representation of the existing process. This step provides a clear understanding of how workflows operate in their current form. Teams document each step, decision point, and interaction to capture the process as it is. This map serves as a baseline for identifying inefficiencies and planning improvements.

To begin, teams should gather input from all stakeholders involved in the process. Observing workflows in action and collecting relevant data ensures accuracy. For example, a manufacturing team might track cycle times for each production stage. Including details such as handoffs, delays, and bottlenecks helps create a comprehensive map.

Tip: Use tools like flowcharts or swimlane diagrams to organize information visually. These tools make it easier to identify areas needing improvement.

Mapping the current state also highlights non-value-added activities. Teams can identify steps that do not contribute to the final product or service. For instance, a retail company might discover that manual data entry slows order processing. By documenting these inefficiencies, teams lay the groundwork for meaningful analysis in the next step.

Step 5: Analyze the Map for Improvement Opportunities

Analyzing the current state map helps teams uncover inefficiencies and prioritize areas for improvement. This step involves examining each process step to determine its value and necessity. Teams use quantitative methods to evaluate performance and identify gaps.

Method | Description |

|---|---|

Reviews the current model for a process, calculating cycle time and efficiency to identify non-value adding time. | |

Queuing Theory | Analyzes the behavior of queues to optimize process flow and resource allocation. |

Process Simulation | Uses models to simulate process performance under various scenarios to identify improvement opportunities. |

For example, flow analysis might reveal that a significant portion of cycle time is spent waiting for approvals. Queuing theory could help optimize resource allocation in a call center, reducing customer wait times. Process simulation allows teams to test changes before implementation, minimizing risks.

Teams should focus on identifying root causes of inefficiencies. For instance, a healthcare provider might find that unclear communication between departments leads to delays in patient care. Addressing these root causes ensures that improvements target the most critical issues.

Note: Prioritize changes that deliver the greatest impact with minimal disruption. This approach maximizes efficiency while maintaining process stability.

Step 6: Design the Future State Map

Designing the future state map involves creating a blueprint for the improved process. This map represents the ideal workflow, incorporating solutions identified during the analysis phase. Teams aim to eliminate inefficiencies, reduce waste, and enhance overall performance.

To design the future state, teams should:

Remove non-value-added steps identified in the current state map.

Streamline workflows to minimize delays and bottlenecks.

Incorporate automation or technology where applicable.

For example, a logistics company might redesign its delivery process to include automated route planning. This change could reduce delivery times and improve customer satisfaction. Similarly, a manufacturing team might reorganize its production line to eliminate redundant steps, boosting efficiency.

Tip: Use process simulation to test the future state map under different scenarios. This ensures that the proposed changes achieve the desired outcomes.

The future state map should align with organizational goals and customer needs. Teams must validate the map with stakeholders to ensure feasibility and buy-in. By creating a clear and actionable plan, organizations set the stage for successful implementation and sustained improvements.

Step 7: Validate and Implement the Process Map

Validating and implementing the process map ensures that the proposed improvements translate into real-world success. This step bridges the gap between planning and execution, ensuring that the process map delivers measurable results.

Validation: Ensuring Accuracy and Feasibility

Validation involves reviewing the process map to confirm its accuracy and practicality. Teams must ensure that the map reflects the actual workflow and aligns with organizational goals. This step minimizes errors and builds confidence in the proposed changes.

Key activities during validation include:

Stakeholder Review: Gather feedback from all relevant stakeholders. Their insights can help identify overlooked steps or potential challenges.

Pilot Testing: Implement the process map on a small scale to test its feasibility. This approach allows teams to identify and address issues before full-scale implementation.

Data Verification: Compare the process map against collected data to ensure consistency. Metrics such as cycle times and defect rates should align with the map's predictions.

Tip: Use simulation tools to model the process map under different scenarios. This technique helps identify potential bottlenecks and ensures the map performs as expected.

Implementation: Turning Plans into Action

Once validated, the process map moves into the implementation phase. This step focuses on executing the proposed changes and integrating them into daily operations. A structured approach ensures a smooth transition and minimizes disruptions.

Steps for successful implementation:

Develop an Action Plan: Outline specific tasks, timelines, and responsibilities. Assign clear roles to team members to ensure accountability.

Provide Training: Equip employees with the skills and knowledge needed to follow the new process. Training sessions and detailed documentation can support this effort.

Monitor Progress: Track key performance indicators (KPIs) to measure the impact of the changes. Metrics such as defect rates, cycle times, and customer satisfaction scores provide valuable insights.

Adjust as Needed: Remain flexible and open to feedback. If issues arise, make necessary adjustments to optimize the process.

Implementation Step | Purpose |

|---|---|

Develop Action Plan | Ensure clarity and accountability |

Provide Training | Prepare employees for new workflows |

Monitor Progress | Track performance and identify issues |

Adjust as Needed | Optimize the process for better results |

Note: Regular communication with stakeholders during implementation fosters transparency and builds trust.

Sustaining Success

After implementation, teams must focus on sustaining the improvements. Regular audits, employee feedback, and process reviews ensure that the changes remain effective over time. By embedding the new workflows into the organization's culture, teams can achieve long-term success.

Callout: Validating and implementing the process map is not a one-time effort. Continuous monitoring and adaptation ensure that the process evolves with changing needs.

Tips for Using Six Sigma Process Mapping Effectively

Engage Stakeholders Throughout the Process

Engaging stakeholders is critical to the success of Six Sigma Process Mapping. Stakeholders bring diverse perspectives that enrich the understanding of workflows and help identify inefficiencies. Their involvement ensures that the process map reflects real-world conditions and aligns with organizational goals. For example, including team members from various departments can uncover hidden bottlenecks or redundant tasks that might otherwise go unnoticed.

Stakeholder engagement also leads to measurable outcomes. Surveys can track satisfaction levels, while influence analysis evaluates the impact of stakeholder contributions. Retention rates, such as attendance at meetings or participation in discussions, indicate ongoing engagement. Financial benefits, measured as return on investment, justify the resources allocated to stakeholder initiatives.

Outcome Type | Description |

|---|---|

Measures stakeholder satisfaction through surveys, helping identify satisfaction levels across different groups. | |

Influence Analysis | Evaluates the impact of various stakeholders on the project, aiding in strategic planning and expectation management. |

Retention Rates | Tracks ongoing engagement through metrics like email interactions and event attendance, indicating stakeholder value. |

Return on Investment | Assesses the financial benefits of engagement against costs, justifying further investment in stakeholder initiatives. |

Tip: Regularly communicate with stakeholders to maintain alignment and ensure their input is valued throughout the process.

Focus on Eliminating Non-Value-Added Activities

Eliminating non-value-added (NVA) activities is a cornerstone of process improvement. These activities consume resources without contributing to the final product or service. Six Sigma Process Mapping visually represents workflows, enabling teams to categorize steps as value-adding, necessary but non-value-adding, or purely wasteful. By focusing on customer needs, organizations can streamline processes and enhance efficiency.

In manufacturing, NVA activities account for 20% of process costs, while in service industries, they contribute to 30% of costs. A time value map can help visualize these inefficiencies. Activities above the timeline add value, while those below represent waste. This clear distinction aids in prioritizing improvements.

Activity Type | Cost Impact |

|---|---|

Manufacturing Process Costs | |

Service Process Costs | 30% attributable to NVA |

Value-adding activities appear above the timeline in a time value map.

Non-value-adding activities fall below, highlighting areas for improvement.

This visualization simplifies decision-making and enhances process efficiency.

Note: Regularly review and update process maps to ensure that eliminated NVA activities do not reappear over time.

Use Visuals to Simplify Complex Processes

Visual tools play a vital role in simplifying complex processes. They provide a clear, step-by-step representation of workflows, making it easier for teams to understand and analyze operations. Flowcharts, swimlane diagrams, and value stream maps are particularly effective in this regard.

Visual Metric | Description |

|---|---|

Flowcharts | Provide a step-by-step visual representation of processes, making them easier to understand. |

Swimlane Diagrams | Help clarify roles and responsibilities within a process, enhancing collaboration. |

Value Stream Maps | Offer a detailed view of processes, highlighting areas for improvement and optimization. |

Using universally recognized symbols ensures that process maps are accessible to all team members, regardless of their technical expertise. Visual representations also help identify inefficiencies and propose solutions. For example, a swimlane diagram can clarify handoffs between departments, reducing delays and improving accountability.

Universally recognized symbols enhance understanding across teams.

Comprehensive visuals track progress and ensure accountability.

Teams can use these tools to identify inefficiencies and propose targeted solutions.

Callout: Incorporate visuals into training materials to ensure that new employees quickly grasp complex workflows.

Regularly Update Maps to Reflect Changes

Process maps are living documents that require regular updates to remain effective. Workflows evolve due to changes in technology, market demands, or organizational goals. Teams must revise process maps to reflect these changes and ensure they continue to drive efficiency and alignment.

Why Updating Process Maps Matters

Outdated process maps can lead to inefficiencies and miscommunication. When workflows change but maps remain static, teams may follow incorrect procedures or overlook new opportunities for improvement. Regular updates keep maps accurate and relevant, enabling organizations to adapt to shifting conditions.

Tip: Schedule periodic reviews of process maps to identify areas that need updates. Quarterly or biannual reviews work well for most organizations.

Steps to Update Process Maps

Teams can follow a structured approach to update process maps effectively:

Review Current Workflows

Observe how processes operate in real-time. Compare the current state to the existing map and note discrepancies.Gather Feedback

Consult stakeholders involved in the process. Their insights can reveal hidden inefficiencies or changes that need documentation.Incorporate Changes

Add new steps, remove outdated ones, and adjust decision points. Ensure the map reflects the latest workflow accurately.Validate Updates

Test the revised map to confirm its accuracy. Use pilot testing or simulations to identify potential issues before full implementation.Communicate Changes

Share the updated map with all relevant teams. Provide training or documentation to ensure everyone understands the new workflow.

Benefits of Regular Updates

Benefit | Impact |

|---|---|

Improved Accuracy | Ensures workflows align with current operations. |

Enhanced Efficiency | Reduces errors caused by outdated procedures. |

Better Collaboration | Keeps teams informed and aligned on process changes. |

Sustained Improvement | Supports continuous optimization efforts. |

Regular updates also foster a culture of adaptability. Teams become more responsive to changes, ensuring the organization remains competitive in dynamic environments.

Real-World Example

A logistics company updated its delivery process map after adopting new routing software. The revised map reduced delivery times by 15% and improved customer satisfaction. This example highlights how regular updates can drive measurable improvements.

Callout: Teams should treat process maps as dynamic tools rather than static documents. Frequent updates ensure maps remain valuable resources for achieving organizational goals.

Six Sigma process mapping plays a pivotal role in achieving operational excellence. By visually representing workflows, it identifies inefficiencies and reduces waste. Tools like SIPOC diagrams clarify process scope, while process mapping pinpoints areas for improvement. This systematic approach minimizes defects and ensures consistent quality. Organizations can apply these techniques to streamline operations and align processes with strategic goals. Continuous improvement remains essential, as regular updates to process maps sustain success and adapt to evolving challenges. Embracing this methodology fosters efficiency, accountability, and long-term growth.

FAQ

What is the primary purpose of Six Sigma process mapping?

Six Sigma process mapping visually represents workflows to identify inefficiencies and optimize processes. It helps teams understand how tasks flow, pinpoint bottlenecks, and eliminate waste. This tool supports continuous improvement and aligns processes with organizational goals.

How does Six Sigma process mapping differ from traditional flowcharts?

While traditional flowcharts outline steps in a process, Six Sigma process mapping integrates data-driven analysis. It focuses on identifying inefficiencies, measuring performance, and aligning workflows with Six Sigma principles. This approach ensures precision and supports continuous improvement.

Can Six Sigma process mapping be applied in non-manufacturing industries?

Yes, Six Sigma process mapping benefits industries like healthcare, logistics, and retail. For example, hospitals use it to streamline patient care, while retailers optimize supply chains. Its versatility makes it valuable across various sectors.

What tools are commonly used for creating process maps?

Teams often use tools like Microsoft Visio, Lucidchart, and Miro to create process maps. These platforms offer templates for SIPOC diagrams, swimlane charts, and value stream maps, simplifying the mapping process.

How often should process maps be updated?

Teams should update process maps regularly, ideally quarterly or biannually. Frequent updates ensure workflows reflect current operations, adapt to changes, and maintain efficiency.

What are the key benefits of using SIPOC diagrams?

SIPOC diagrams provide a high-level overview of processes, highlighting suppliers, inputs, outputs, and customers. They clarify process boundaries, align stakeholders, and identify inefficiencies early in the improvement cycle.

How does process mapping support decision-making?

Process mapping provides data-driven insights into workflows. Metrics like cycle times and defect rates help teams prioritize improvements and allocate resources effectively. This approach ensures decisions align with organizational goals.

Is training required to implement Six Sigma process mapping?

Yes, training ensures teams understand mapping techniques and Six Sigma principles. Workshops, online courses, and certifications provide the necessary skills to create accurate and actionable process maps.

Tip: Encourage team collaboration during training to foster a shared understanding of workflows.