3 ways Lean Methodology saves you time

Lean Methodology helps systems and teams work smarter by cutting waste, making every process run smoother, and encouraging ongoing improvement. Many businesses, such as those using Hiring Systems, have seen faster results and higher customer satisfaction after following simple optimization steps. For example, companies that organized documents and used digital tools improved efficiency and reduced wait times. These changes lead to better quality, more profit, and happier clients. Anyone can use Lean to boost value and save time. Reach out to learn how your team can benefit.

Key Takeaways

Lean Methodology saves time by cutting waste, simplifying steps, and encouraging ongoing improvements.

Identifying and removing waste like delays, extra steps, and unused resources boosts efficiency and lowers costs.

Streamlining processes with clear instructions and technology reduces errors and speeds up work.

Continuous improvement helps teams make small changes regularly to keep workflows smooth and flexible.

Using tools like value stream mapping and root cause analysis makes spotting problems easier.

Standardizing work and training employees ensure consistent quality and faster task completion.

The pull system matches work to real customer demand, preventing overproduction and delays.

Starting Lean with clear goals, leadership support, and small wins leads to lasting success.

Eliminating Waste

Eliminating waste stands as a core principle in Lean Methodology. Systems and teams that focus on waste reduction see faster results and smoother workflows. Waste in business processes often hides in plain sight, slowing down operations and increasing costs. By learning to spot and remove these inefficiencies, organizations can save significant time and resources.

Types of Waste

Workflow Waste

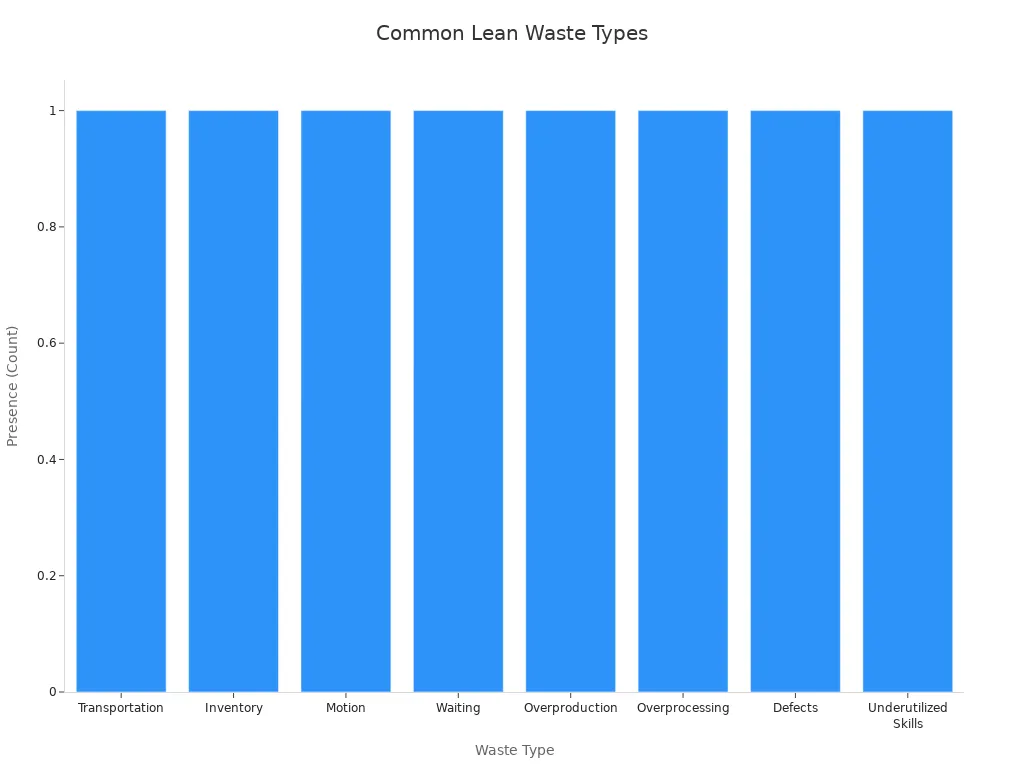

Workflow waste includes unnecessary steps, delays, and bottlenecks that prevent smooth progress. Waiting waste, for example, happens when people, materials, or equipment sit idle. This idle time leads to direct delays and lost productivity. Poor communication, equipment downtime, and production bottlenecks often cause waiting waste. When teams address these issues, they reduce lead times and improve overall efficiency.

Resource Waste

Resource waste refers to the misuse of materials, labor, or equipment. Overproduction, excess inventory, and unnecessary motion all fall into this category. For instance, producing more items than needed creates extra handling and storage time. Unused talent also counts as waste, as it means not using employees’ skills for problem-solving or process improvement.

Tip: Teams can use visual tools like value stream mapping to spot both workflow and resource waste quickly.

Identifying Waste

Tools for Detection

Lean Methodology offers practical tools for waste detection. Value stream mapping helps teams visualize each step in a process and highlight non-value-added activities. Root cause analysis uncovers why waste occurs, while standardized work instructions reveal inconsistencies. Many organizations now use continuous improvement software to automate waste reporting and track progress in real time.

Common Signs

Common signs of waste include frequent delays, excess inventory, repeated rework, and unnecessary movement. Teams may notice long wait times between steps or see employees walking back and forth due to poor layout. These signs signal opportunities for improvement.

Waste Type | Description | Impact on Time Management | Example/Explanation |

|---|---|---|---|

Waiting | Idle time between steps | Lost productive time, increased costs | Equipment downtime, waiting for materials |

Overproduction | Producing more than needed | Extra handling, storage time | Parts made before needed |

Motion | Unnecessary movement by people | Wasted time through inefficient motions | Poor workstation layout |

Defects | Faulty products needing rework | Time spent on rework, delayed delivery | Defective parts |

Removing Waste

Quick Fixes

Teams can start with simple changes. Rearranging workstations to reduce motion, setting clear work instructions, and using digital tools for faster communication all help eliminate waste quickly. For example, systems and teams that switched to automated quality control detected defects faster and increased throughput.

Long-Term Actions

Long-term solutions involve redesigning workflows, adopting pull systems, and engaging employees in continuous improvement. Companies like FedEx Express and Harley-Davidson used Lean tools such as value stream mapping and Kaizen to cut lead times and reduce transportation waste. These changes led to faster delivery and lower costs.

Note: Systems and teams that want to learn more about eliminating waste and boosting efficiency can reach out for tailored guidance.

Streamlining Processes

Streamlining processes helps systems and teams work faster and more efficiently. Lean Methodology focuses on removing unnecessary steps, reducing errors, and making every task easier to complete. When organizations simplify and standardize their workflows, they save time and improve results for both employees and customers.

Simplifying Steps

Mapping Processes

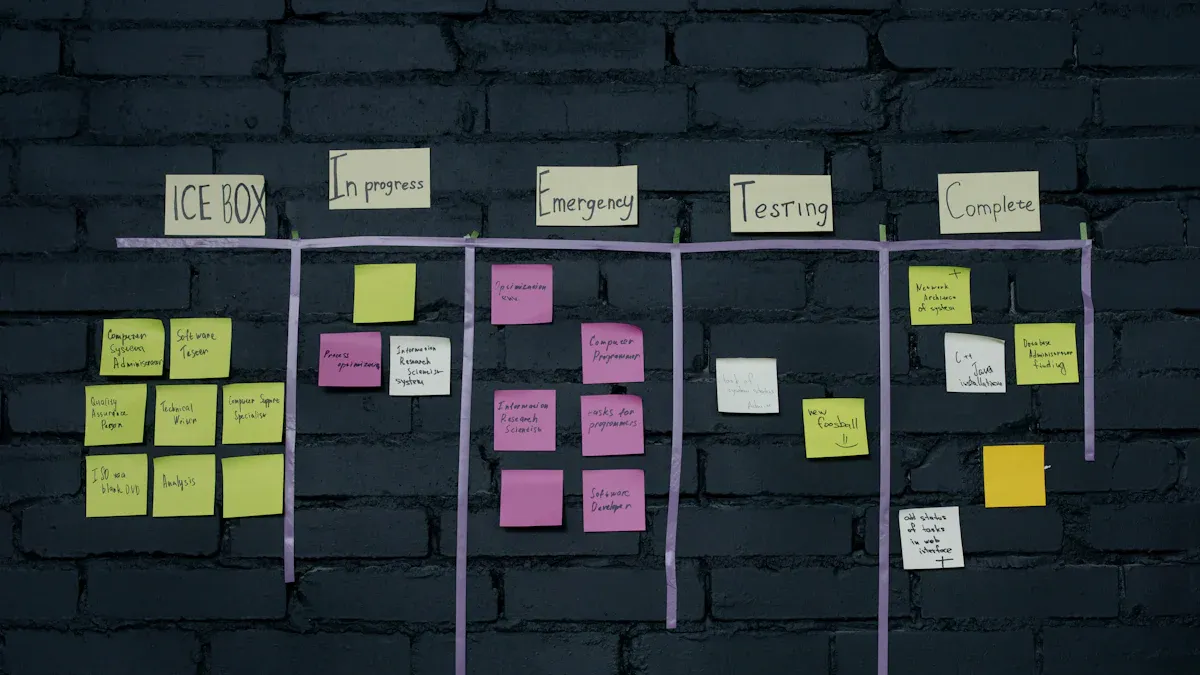

Teams often start by mapping out each step in their workflow. This visual approach helps everyone see where time gets lost or where tasks pile up. Tools like Kanban boards allow teams to track work in progress, spot blockers, and limit the number of tasks at once. By using process maps, systems and teams can identify steps that do not add value and remove them.

Reducing Bottlenecks

Bottlenecks slow down progress and create frustration. Teams use Lean tools such as value stream mapping and root cause analysis to find and fix these problem areas. For example, automating repetitive tasks speeds up processes and reduces waiting times for approvals. Digital workflows also cut down on paperwork and manual errors, making it easier to complete tasks quickly.

Tip: Regularly reviewing and simplifying processes helps maintain efficiency and prevents old problems from returning.

Standardizing Work

Clear Procedures

Standardizing work means creating clear, step-by-step instructions for every task. This reduces confusion and ensures everyone follows the same process. In manufacturing, standardized work instructions have saved up to 32 days per year by cutting down on changeover time. Electronic work instructions make it easy for operators to access the latest procedures, check quality, and collect data in real time.

Benefit Area | Summary | Example/Source |

|---|---|---|

Consistency & Quality | Standardized processes reduce variability and ensure consistent results. | McDonald's delivers the same menu and quality worldwide. |

Time Savings | Clear instructions reduce downtime and speed up changeovers. | Lean pioneers Taiichi Ohno and Shingo Shigeo cut changeover times drastically. |

Scalability & Training | Standardization makes it easier to train new team members and expand operations. | Walmart improved consistency by standardizing wage structures. |

Team Training

Training ensures that everyone understands the procedures and can perform tasks correctly. Frequent communication and hands-on practice help teams stay aligned. When employees know exactly what to do, they make fewer mistakes and complete work faster.

Reducing Delays

Faster Handoffs

Delays often happen when work passes from one person or department to another. Streamlined handoffs, supported by clear documentation and alerts, prevent tasks from getting stuck. Hospitals using Lean reduced patient waiting times from two hours to thirty minutes by improving handoffs and eliminating unnecessary steps.

Using Technology

Technology plays a key role in reducing delays. Centralized communication tools help teams coordinate quickly and avoid miscommunication. Automated systems handle repetitive tasks, freeing up employees to focus on more important work. Digital solutions also make it easier to track progress and spot issues early.

Streamlining reduces time and effort on tasks, allowing teams to focus on value-added activities.

Simplifying processes minimizes errors and boosts customer satisfaction.

Eliminating unnecessary approvals accelerates decision-making and workflow.

Optimizing resources leads to cost savings and higher morale.

Systems and teams that want to learn more about streamlining processes can reach out for tailored guidance and support.

Continuous Improvement

Continuous improvement stands at the heart of Lean Methodology. Systems and teams that focus on ongoing changes see lasting gains in efficiency and time savings. By making small adjustments and building a culture of improvement, organizations keep processes sharp and responsive.

Ongoing Changes

Small Adjustments

Small, incremental changes help systems and teams improve without major disruptions. These adjustments might include rearranging a workspace, updating a checklist, or tweaking a workflow. Over time, these small steps add up to big results. Teams that regularly review their processes can spot bottlenecks and remove waste, which leads to shorter cycle times and less waiting.

Regular improvements keep systems and teams flexible and ready to meet new challenges.

Building Culture

A culture of continuous improvement encourages everyone to look for better ways to work. Leaders support this by setting clear goals and sharing data openly. When employees feel empowered to suggest changes, they take ownership of their work. This mindset helps organizations adapt quickly and stay efficient, even as needs change.

Long-term thinking embeds Lean practices into daily routines.

Leadership involvement boosts motivation and accountability.

Focus on customer value ensures that every improvement matters.

Lean Methodology Tools

Feedback Loops

Feedback loops play a key role in continuous improvement. Systems and teams collect data on performance, review results, and make adjustments. Tools like Plan-Do-Check-Act (PDCA) cycles, Kaizen events, and Kanban boards help teams test ideas and track progress. These tools make it easy to spot problems early and fix them before they grow.

Progress Tracking

Tracking progress keeps everyone focused on improvement goals. Teams use key performance indicators such as cycle time, inventory turnover, and machine downtime. Regular monitoring helps identify trends and measure the impact of changes. Visual management tools, like charts and dashboards, make results clear for everyone.

Tool | Purpose | Result |

|---|---|---|

5S | Organize and clean workspaces | Less waste, more efficiency |

Kaizen | Involve everyone in small improvements | Ongoing learning, innovation |

SMED | Reduce changeover times | Faster setups, less downtime |

Value Stream Mapping | Visualize and improve process flow | Fewer bottlenecks |

Preventing Time Loss

Early Problem Solving

Early problem solving prevents small issues from becoming big delays. Teams use root cause analysis and mistake-proofing (poka-yoke) to fix problems at their source. By acting quickly, systems and teams avoid wasted time and keep work moving smoothly.

Staying Flexible

Flexibility allows organizations to adjust when conditions change. Lean Methodology supports this by encouraging regular reviews and updates. Teams that stay open to new ideas can adapt processes, reduce idle time, and maintain high performance.

Systems and teams that want to learn more about building a culture of continuous improvement can reach out for tailored support.

Lean Methodology Principles

Customer Value

Customer value stands as the first principle in Lean Methodology. Systems and teams begin by understanding what customers truly need. They use surveys and interviews to gather direct feedback. This approach ensures that every process aligns with customer expectations. When teams focus on value, they avoid spending time on tasks that do not matter to the customer. For example, software companies often prioritize features that users request, which leads to faster development and higher satisfaction.

Focusing on customer value helps systems and teams eliminate unnecessary steps, reduce turnaround time, and improve delivery speed. Virginia Mason Medical Center used this principle to cut patient wait times by 40%. Toyota also improved efficiency by matching production to real customer demand.

Aspect | Explanation | Example/Result |

|---|---|---|

Defining Value | Teams identify what customers want through direct engagement. | Software companies focus on user-friendly features. |

Value Stream Mapping | Teams visualize all steps to find waste. | Lead time and wait time highlight inefficiencies. |

Creating Flow | Teams organize work to reduce bottlenecks. | Rearranging workstations cuts wait times. |

Case Studies | Real-world results show time savings. | |

Continuous Improvement | Teams refine processes based on feedback. | Lean teams sustain time savings. |

Value Stream

The value stream principle guides systems and teams to map every step needed to deliver a product or service. Teams create a current state map that shows all actions, wait times, and cycle times. This map makes waste visible, such as unnecessary meetings or delays. By analyzing the map, teams can spot bottlenecks and remove steps that do not add value.

A typical value stream mapping process includes:

Documenting all steps, including wait and cycle times.

Identifying sources of waste like waiting or overproduction.

Designing a future state map that removes waste.

Creating an action plan with clear timelines.

Using metrics like lead time and work in process to track progress.

Applying Lean techniques such as Kaizen and Kanban to improve flow.

Teams often find that value stream mapping reveals opportunities for at least 20% immediate time savings. For example, eliminating unnecessary meetings can save days over the course of a year. By making waste visible, systems and teams can optimize their time and increase their capacity for innovation.

Flow

Flow means ensuring that work moves smoothly and continuously through each process step. Systems and teams strive to remove interruptions, delays, and bottlenecks. When flow improves, tasks get completed faster and with fewer errors. For example, a logistics company consolidated driver apps into one, saving each driver 30 minutes per day. Moving inventory management to the cloud reduced downtime by 99%, which sped up order processing.

Flow optimization involves defining and refining processes to keep work steady.

Teams limit work in process to avoid overload and maintain speed.

Benefits include reduced lead time, predictable delivery, and higher productivity.

Example Metrics and Description | |

|---|---|

Cost Metrics | Cost of Poor Quality, Labor Cost per Unit, Waste Reduction — show financial impact of waste reduction. |

Inventory Metrics | Work in Progress, Days of Inventory on Hand — reveal bottlenecks and excess inventory. |

Capacity & Utilization | Capacity Utilization Rate, Machine Downtime — measure resource use and reduce downtime. |

Productivity Metrics | Overall Equipment Effectiveness, Units Produced per Hour — measure production efficiency. |

Safety and Morale Metrics | Employee Suggestion Rate, Turnover — reflect workforce engagement and safety. |

Systems and teams that focus on flow see faster results and more reliable processes. They can reach out to learn how to apply these principles for greater efficiency.

Pull System

The pull system stands as a key principle in Lean Methodology. It helps systems and teams produce only what customers need, when they need it. This approach prevents overproduction and reduces wasted resources. Instead of making products based on forecasts, teams wait for a clear signal from the next step in the process before starting work.

The pull system aligns production with real customer demand. This means systems and teams avoid building up extra inventory or tying up money in unsold goods.

Production begins only when there is a specific request. This method improves responsiveness and keeps workloads steady.

Tools like Kanban and just-in-time inventory support the pull system. These tools signal when to start or stop production, making sure nothing gets made unless needed.

The system reacts quickly to changes in demand. Teams can adjust their work without causing delays or shortages.

Problems in the process become visible right away. Teams can fix issues before they grow, which supports continuous improvement.

The pull system creates a healthy tension in the workflow. It exposes problems early and encourages quick solutions, which helps systems and teams save time and reduce waste.

By using the pull system, organizations match their work to real-time needs. This approach stabilizes operations, minimizes delays, and supports better cash flow. Systems and teams that want to learn more about using the pull system can reach out for guidance.

Perfection

Perfection in Lean Methodology means always looking for ways to improve. Systems and teams never settle for "good enough." They focus on removing waste, streamlining steps, and making every process better over time.

Many companies have seen big results by aiming for perfection. For example, a pharmaceutical company removed extra quality checks and simplified inventory management. This change sped up production and lowered costs.

A consumer goods manufacturer used Lean and the pull system to switch to a demand-driven model. This shift reduced inventory costs and made the company more responsive to customer needs.

Digital tools now help teams track progress in real time. Automated workflows and data analytics make it easier to spot bottlenecks and fix them quickly.

The pursuit of perfection is a continuous journey. Teams work together to find and remove waste, improve processes, and empower employees to suggest changes.

In many industries, such as healthcare and financial services, Lean Methodology has helped reduce delays and errors. Hospitals have used Lean to cut waiting times and improve patient care. Accounting teams have shortened lead times for financial transactions. Startups use Lean to adapt quickly and focus on what matters most.

The drive for perfection encourages systems and teams to keep learning and improving. By using digital tools and sharing best practices, they can respond faster and deliver better results. Anyone interested in building a culture of continuous improvement can reach out for support and resources.

Real-World Applications

Small Business

Small businesses often face challenges with limited resources and tight schedules. Many have turned to Lean Methodology to improve efficiency and save time. For example, a local bakery used Lean Six Sigma to analyze its production process. The team reduced the time needed for each batch, which helped them meet customer demand more effectively. A small manufacturing company adopted just-in-time inventory management and improved communication with suppliers. This change cut lead times and lowered costs. A boutique clothing store optimized inventory management, which reduced stockouts and improved customer satisfaction.

A small hard cider manufacturer struggled with disorganized inventory and equipment issues. The team standardized practices and organized workspaces. They optimized procedures, which eliminated downtime between batches and improved product quality. The company reclaimed storage space and maintained a continuous production flow. These improvements allowed the business to meet customer demand efficiently without overbuilding inventory.

Systems and teams in small businesses can use Lean tools to streamline operations and respond quickly to market changes.

Healthcare

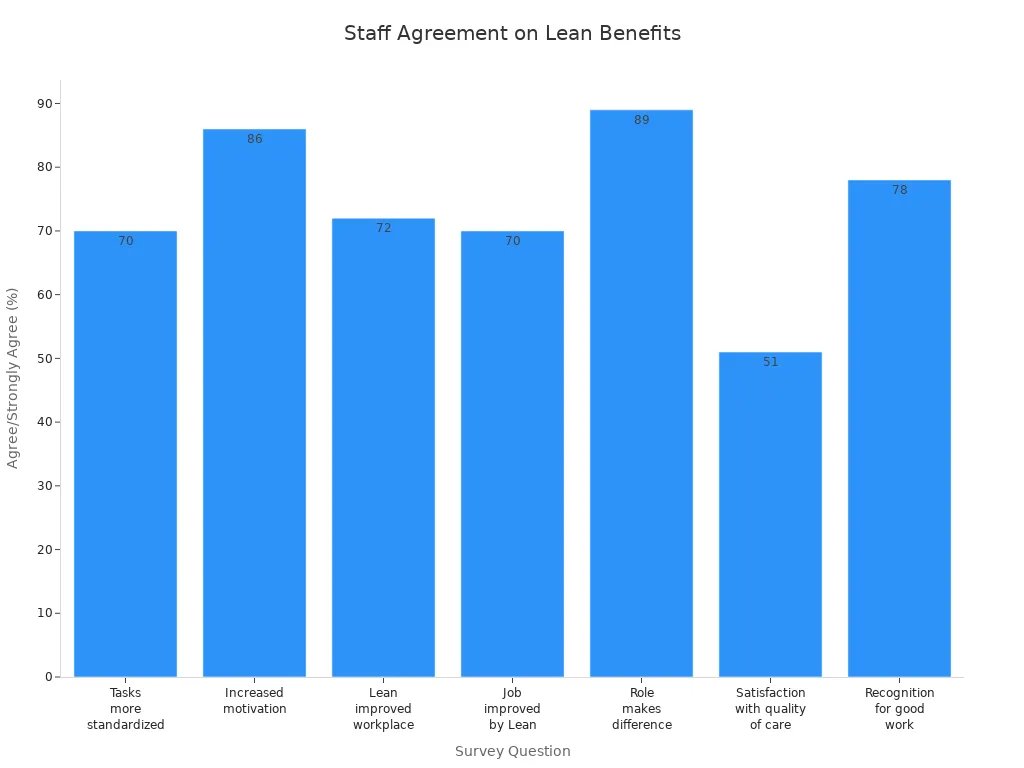

Healthcare organizations use Lean Methodology to improve patient care and reduce waiting times. Emergency departments often experience delays and overcrowding. By targeting non-value-added activities, teams streamline patient flow and improve care quality. At King Hussein Cancer Center, Lean strategies reduced patient waiting times in the outpatient pharmacy. Staff surveys showed high agreement that Lean improved workflow standardization, motivation, and workplace quality.

Survey Question | Agree/Strongly Agree (%) |

|---|---|

Tasks more standardized avoiding waste | ~70% |

Increased motivation in efficiency-focused environment | ~86% |

Lean improved workplace | ~72% |

Job improved by Lean | ~70% |

Role makes a difference to patients | ~89% |

Satisfaction with quality of care | ~51% |

Recognition for good work | ~78% |

At the University of Virginia's Gynecologic Oncology outpatient clinic, teams mapped patient flow and identified key waiting points. Process changes reduced overall patient waiting times and improved clinic efficiency. These results increased patient satisfaction and supported expanded clinical trial capacity.

Systems and teams in healthcare can reach out to learn how Lean can help reduce delays and improve care.

Manufacturing

Manufacturing companies have seen major time savings by applying Lean Methodology. The approach focuses on eliminating seven types of waste, such as overproduction, defects, and unnecessary motion. By removing these wastes, teams achieve higher quality products and faster processes.

Lean Implementation Phase | Key Time-Saving Outcomes | Supporting Lean Tools/Methods |

|---|---|---|

Phase 1: Stability | 5-10% cost reduction; foundation for further improvements | Standardized work, visual management |

Phase 2: Flow | Lead time reduction by 50-80%; inventory cost cut by 20-40% | Production cells, pull systems (Kanban) |

Phase 3: Quality | Defect rate reduction by 50-90% | Error-proofing, process control |

Phase 4: Supplier Partnerships | Material cost reduction by 5-15% | Supplier development |

An electronics manufacturer reduced waiting time by 70% and increased throughput by 25%. Lean tools like 5S, Kaizen events, and Value Stream Mapping helped improve productivity and reduce non-value-added activities.

Systems and teams in manufacturing can use Lean to shorten cycle times and deliver products faster. For tailored guidance, they can reach out to learn more.

Getting Started

First Steps

Systems and teams can begin their Lean journey by following a clear set of actions. These steps help create a strong foundation for improvement and time savings:

Identify the client and define value from the client's perspective. Understanding who benefits from the service helps determine what adds value and what creates waste.

Use Value Stream Mapping to visualize all process steps. This tool makes it easier to spot delays, extra steps, and other forms of waste.

Create a compelling reason for Lean adoption. Motivation encourages everyone to participate and support the changes.

Dedicate enough resources to Lean efforts. Teams should avoid simply adding Lean tasks to already full workloads.

Educate both staff and clients about what the client values. Training builds understanding and support.

Start with manageable improvements. Focus on small, continuous wins rather than large, one-time changes.

Assign clear responsibilities and empower employees to make improvements.

Apply the Plan-Do-Check-Act (PDCA) cycle. This method allows teams to test and refine changes before full implementation.

A steering committee with diverse stakeholders can guide the process. Teams should also set high-level objectives, identify initial projects, and develop a flexible deployment plan. Communication and risk management plans help keep everyone informed and prepared.

Common Pitfalls

Many systems and teams face challenges when starting Lean initiatives. Awareness of these pitfalls can help prevent setbacks:

Weak leadership support

Resistance to change among staff

Inadequate training and education

Poor communication between departments

Low employee engagement

Over-reliance on Lean tools without focusing on culture

Failure to monitor progress and adapt

To avoid these issues, teams should secure strong leadership commitment, engage employees through training and open communication, and focus on building a culture of continuous improvement. Regular progress checks and flexibility help maintain momentum.

Tip: Recognize and reward Lean efforts to encourage ongoing participation and improvement.

Resources

Many resources support systems and teams as they learn and apply Lean practices. ASQ offers articles, case studies, and books that cover Lean culture, implementation strategies, and industry-specific examples. These materials explain both the theory and practical tools needed for success. Lean learning, inspired by the Toyota Production System, extends beyond manufacturing. It focuses on eliminating waste in training, empowering employees, and aligning learning with customer value. Techniques such as A3 thinking, visual management, and lean instructional design foster a culture of continuous improvement.

Organizations benefit from resources that emphasize both continuous improvement and respect for people. Empowering frontline workers and involving them in decision-making leads to better results. Lean leadership supports this by giving employees autonomy and purpose. These principles help systems and teams across industries deliver value and build resilience.

Systems and teams interested in starting or improving their Lean journey can reach out for tailored guidance and support.

Lean Methodology helps systems and teams save time by eliminating waste, streamlining processes, and driving continuous improvement. Many organizations achieve rapid results by focusing on just one Lean principle:

Organization | Lean Principle | Rapid Results Achieved |

|---|---|---|

Toyota | Just-in-time, Kaizen | |

Harley-Davidson | Pull systems | Lead time cut from 21 days to 6 hours |

Intel | Single-piece flow | 70% cycle time reduction |

Lean Methodology works for any business or individual:

It began in manufacturing but now improves healthcare, retail, and more.

Teams at all levels can use Lean tools for quick wins.

Real-world case studies show measurable gains in efficiency and quality.

Systems and teams can start small—try mapping one process or using a Kanban board. Share your results and help build a culture of improvement. Reach out to learn how Lean can benefit your organization.

FAQ

What is Lean Methodology?

Lean Methodology helps systems and teams remove waste, improve processes, and deliver more value. It uses simple tools and clear steps. Many industries use Lean to save time and boost efficiency.

How do systems and teams identify waste?

Teams use tools like value stream mapping and root cause analysis. These tools help spot delays, extra steps, and unused resources. Systems and teams can reach out for guidance on using these tools.

Can Lean work outside manufacturing?

Yes. Lean works in healthcare, retail, education, and small businesses. Systems and teams in any field can use Lean principles to improve workflows and save time.

What are the first steps to start Lean?

Start by mapping current processes and identifying waste. Set clear goals and involve everyone. Systems and teams often see quick wins by focusing on one process at a time.

How does Lean support continuous improvement?

Lean encourages regular reviews and small changes. Teams track progress and use feedback to make things better. This approach helps systems and teams stay flexible and efficient.

Do systems and teams need special software for Lean?

No special software is required. Many teams use simple tools like whiteboards or spreadsheets. Digital tools can help track progress, but Lean works with basic resources.

How can systems and teams measure Lean success?

Teams measure success with metrics like lead time, cycle time, and error rates. Regular tracking shows improvements. For more details, systems and teams can reach out for support.

Where can systems and teams learn more about Lean?

Many resources exist, including books, online courses, and professional organizations. Systems and teams can also reach out to experts for tailored advice and training.