How Lean Thinking Creates Value and Reduces Waste

Lean Thinking empowers organizations to deliver value by prioritizing customer needs and eliminating inefficiencies. This approach enhances processes, reduces waste, and fosters continuous improvement. For example, companies adopting Lean Thinking have reported a 50% reduction in cycle time and a 25% increase in customer order accuracy. By streamlining operations, businesses can achieve higher efficiency and quality. Whether applied to hiring systems, sales strategies, or broader business management, Lean Thinking drives measurable results and improves customer satisfaction.

Key Takeaways

Lean Thinking focuses on what customers want and need most.

Finding and removing waste makes work faster and customers happier.

Mapping steps in work shows problems and helps fix them.

Smooth workflows cut delays and make work better for everyone.

A pull system matches production to what customers actually need.

Improving all the time encourages new ideas and better processes.

Leaders help teams use Lean Thinking by supporting and working together.

Talking with workers and valuing their ideas helps change happen smoothly.

What Is Lean Thinking?

Definition and Core Purpose

Lean Thinking is a systematic approach to creating value while minimizing waste. Industry experts define it as a continuous journey that requires dedication to understanding and applying Lean principles and techniques. It begins with identifying what the customer values and solving their problems. Lean Thinking emphasizes respect for people, trust, and a mindset shift toward improvement.

At its core, Lean Thinking focuses on achieving perfect value with zero waste. This involves continuous experimentation to refine processes and eliminate inefficiencies. Organizations adopting Lean Thinking often experience significant benefits, including improved quality, reduced costs, and enhanced customer satisfaction. For example, studies show that only 5% of activities in typical workflows add value, while 60% are pure waste. By addressing these inefficiencies, Lean Thinking transforms operations into streamlined, value-driven systems.

Definition/Characteristic | Description |

|---|---|

Lean Thinking | A continuous journey requiring dedication to understand and apply Lean principles and techniques. |

Customer Focus | Always starts with understanding what the customer values and the problems they need to solve. |

Five Principles | Includes identifying value, mapping value creation, creating flow, establishing a pull system, and seeking improvement. |

Origins and Evolution

Lean Thinking originated from the Toyota Production System (TPS), developed between 1948 and 1975 by Taiichi Ohno and Eiji Toyoda. This system revolutionized manufacturing by focusing on efficiency and waste reduction. In 1988, John Krafcik introduced the term "Lean" to describe the principles underlying TPS. His work highlighted how Lean Thinking could optimize processes and reduce resource consumption.

The concept gained widespread recognition in 1990 with James P. Womack's book The Machine That Changed the World. This publication expanded Lean Thinking beyond manufacturing, encouraging its adoption in healthcare, service industries, and office environments. Today, Lean Thinking continues to evolve, integrating modern tools and techniques to address challenges in diverse sectors.

Origins: Developed as part of the Toyota Production System (TPS) between 1948 and 1975.

Introduction of Lean: Officially coined by John Krafcik in 1988.

Widespread Adoption: Popularized by James P. Womack’s book in 1990, leading to applications beyond manufacturing.

Lean Thinking as a Value-Creation Framework

Lean Thinking serves as a powerful framework for creating value in modern business models. It extends beyond operational improvements to foster innovation and design. By identifying customer needs and eliminating waste, Lean Thinking enables organizations to deliver products and services that align with market demands.

Lean teams play a crucial role in this process. They research, design, and develop innovations that transform abstract ideas into validated implementations. For example, Lean Design & Development helps businesses refine their offerings by focusing on customer value. This approach ensures that resources are allocated efficiently, resulting in higher returns on investment and improved customer satisfaction.

Lean principles foster innovation and design in business models.

Lean Design & Development identifies customer value and eliminates waste.

Lean teams transform ideas into validated implementations, driving business success.

The Five Principles of Lean Thinking

Define Value

Defining value is the foundation of Lean Thinking. It begins with understanding what the customer truly needs and values. Organizations must identify the specific products or services that solve customer problems or fulfill their desires. This principle emphasizes delivering exactly what the customer is willing to pay for, without unnecessary features or processes.

For example, a software company might define value as creating a user-friendly application that simplifies a specific task for its users. By focusing on this goal, the company avoids wasting resources on features that do not enhance the user experience. Defining value ensures that every effort aligns with customer expectations, leading to higher satisfaction and loyalty.

Tip: To define value effectively, businesses should engage directly with customers through surveys, interviews, or feedback sessions. This approach helps uncover insights into what matters most to them.

Map the Value Stream

Mapping the value stream involves visualizing all the steps required to deliver a product or service to the customer. This process helps identify which activities add value and which create waste. By analyzing the value stream, organizations can pinpoint inefficiencies and streamline their workflows.

Key metrics often used to map the value stream include:

Lead Time: The total time from receiving a customer order to delivering the product or service.

Cycle Time: The time required to complete all work elements before repeating them.

Wait Time: The time spent waiting between value-adding steps.

Metric | Description |

|---|---|

Lead time | The total time from receiving a customer order to delivering the product/service |

Process time | The actual working time required to complete a process step |

Wait/queue time | Time spent waiting between value-adding steps |

Value-added ratio | The percentage of total lead time spent on value-adding activities |

Cycle Time | The time an operator requires to complete all the work elements before repeating them |

DownTime | Production time lost due to planned or unplanned stoppages |

Uptime | The percent of the time that a machine is available for production |

Changeover time | The time required to set up a machine to make a different product or part number |

% Complete and accurate | The percent of product completed with perfect quality in a process step |

Availability | The time a process operates over a single shift, often measured in seconds |

By using these metrics, businesses can gain a clearer picture of their operations. For instance, reducing lead time and wait time can significantly improve delivery speed and customer satisfaction. Mapping the value stream also fosters collaboration among teams, as it provides a shared understanding of the workflow.

Create Flow

Creating flow ensures that value-adding activities occur without interruptions or delays. A smooth flow minimizes bottlenecks, reduces waste, and accelerates the delivery of products or services. This principle focuses on organizing processes so that work progresses seamlessly from one step to the next.

In manufacturing, for example, creating flow might involve rearranging workstations to eliminate unnecessary movement of materials. In service industries, it could mean redesigning customer service processes to reduce wait times. The goal is to eliminate obstacles that disrupt the flow of value to the customer.

Note: A well-designed flow not only improves efficiency but also enhances employee morale. Workers experience less frustration when processes are streamlined and predictable.

Organizations that successfully create flow often see benefits such as reduced production errors, improved inventory control, and increased productivity. These outcomes contribute to higher profitability and a better customer experience.

Benefit | Description |

|---|---|

Improved Customer Experience | Consistent commitment to Lean enables customers to feel their needs are considered, fostering greater brand loyalty. |

Cost Reduction | Eliminating inefficiencies reduces waste of resources, leading to lower costs and increased profitability. |

Reduced Production Errors | Streamlined processes minimize opportunities for mistakes, enhancing product quality and customer satisfaction. |

Enhanced Inventory Control | Lean methodology allows for better inventory management, aligning production with customer demand and reducing excess stock. |

Boosted Employee Morale | Engaging employees in process improvement fosters a sense of empowerment and boosts morale, leading to higher quality production. |

Continuous Improvement Culture | Lean encourages ongoing evaluation of processes, creating a culture focused on innovation and value enhancement. |

Increased Productivity | Improved team cohesion and engagement result in higher productivity levels, contributing to greater efficiencies and profitability over time. |

By focusing on flow, businesses can achieve faster turnaround times and deliver greater value to their customers.

Establish Pull

Establishing pull ensures that production and inventory align with actual customer demand. This principle eliminates overproduction, reduces waste, and improves efficiency. Instead of pushing products through the system based on forecasts, pull systems activate production only when there is a clear demand. This approach creates a more responsive and flexible workflow.

Pull systems often rely on Just-In-Time (JIT) inventory management. JIT aligns stock levels with real-time demand, minimizing excess inventory and reducing storage costs. For example:

Demand-driven replenishment triggers production based on actual orders, avoiding unnecessary stock buildup.

Accurate forecasting becomes essential to maintain steady manufacturing and prevent disruptions.

By implementing pull systems, businesses can achieve better inventory control and reduce waste. This method also fosters a leaner supply chain, as resources are allocated more effectively. Companies adopting pull systems often report significant cost savings and improved customer satisfaction.

Tip: To establish pull effectively, organizations should invest in demand forecasting tools and maintain close communication with suppliers. This ensures that production schedules remain synchronized with customer needs.

Pursue Continuous Improvement

Continuous improvement, or "Kaizen," lies at the heart of Lean Thinking. This principle encourages organizations to consistently evaluate and refine their processes. Small, incremental changes can lead to significant long-term benefits. Teams focus on identifying inefficiencies, testing solutions, and implementing improvements.

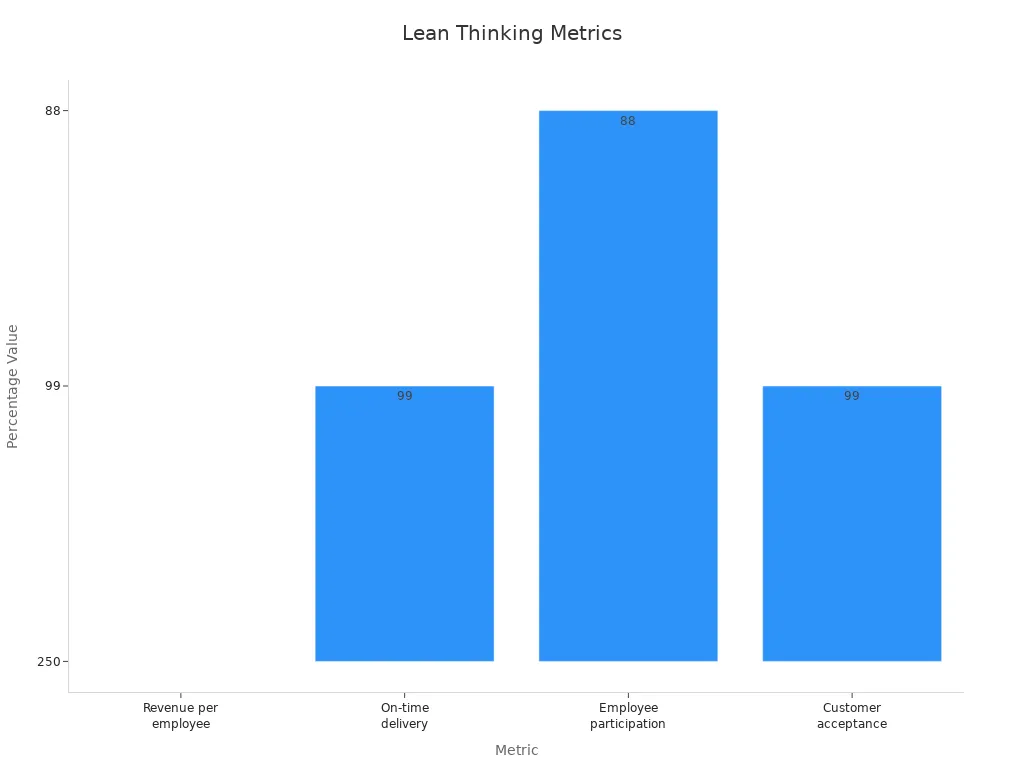

Metrics play a crucial role in measuring the success of continuous improvement initiatives. For instance:

Metric | Value |

|---|---|

Revenue per employee | |

On-time delivery rate | Rose from 80% to 99% |

Employee participation | Achieved 88% |

Customer acceptance rate | Increased to over 99% |

Estimated value of suggestions | $500,000 |

New sales influenced by the game | $1,000,000 |

Organizations that embrace continuous improvement often experience enhanced employee engagement. Workers feel empowered to contribute ideas and take ownership of their roles. This culture of collaboration fosters innovation and drives better results. For example, companies have reported increased revenue per employee and higher customer acceptance rates due to Lean Thinking practices.

Note: To sustain continuous improvement, leadership must actively support and encourage employee participation. Recognizing contributions and celebrating successes can motivate teams to remain committed to the process.

By pursuing continuous improvement, businesses can adapt to changing market conditions, enhance operational efficiency, and deliver greater value to customers.

How Lean Thinking Creates Value

Focusing on Customer Needs

Lean Thinking prioritizes understanding and addressing customer needs. Organizations that adopt this approach begin by identifying what customers value most. This insight guides the development of products and services that solve problems or fulfill desires. Teams use tools like customer feedback surveys and focus groups to gather actionable insights.

For example, Virginia Mason Medical Center implemented Lean tools to improve patient flow. By focusing on patient needs, the healthcare system reduced wait times by 40% and enhanced satisfaction levels. This case illustrates how Lean Thinking aligns processes with customer expectations, creating substantial value.

Tip: Businesses can improve customer focus by fostering collaboration between departments. Sharing insights across teams ensures that every aspect of the organization contributes to meeting customer needs.

Delivering Value-Adding Activities

Lean Thinking emphasizes eliminating non-value-adding activities to maximize efficiency. Teams analyze workflows to identify steps that contribute directly to delivering value. Activities that do not enhance the customer experience or product quality are streamlined or removed.

Toyota Motor Corporation provides a compelling example. By implementing Just-in-Time (JIT) production, Toyota reduced waste and inventory costs significantly. This approach ensures that resources are allocated to activities that directly benefit the customer.

Case Study | Industry | Lean Tools Implemented | Results Achieved |

|---|---|---|---|

Toyota Motor Corporation | Manufacturing | Just-in-Time (JIT) production | Significant reduction in waste and inventory costs |

Virginia Mason Medical Center | Healthcare | Lean tools for patient flow | 40% reduction in wait times, increased patient satisfaction |

Walmart | Retail | Lean and Six Sigma methodologies | Significant cost savings and agile supply chain |

By focusing on value-adding activities, organizations can improve operational efficiency and deliver better outcomes for their customers.

Improving Product and Service Quality

Lean Thinking enhances product and service quality by fostering a culture of continuous improvement. Teams regularly evaluate processes to identify areas for refinement. Metrics such as defect rates, product returns, and customer complaints provide valuable insights into quality performance.

Number of defects: A lower count indicates higher reliability.

Product returns: Fewer returns suggest improved quality.

Customer complaints: A reduction in complaints reflects better customer satisfaction.

Organizations that adopt Lean Thinking often see measurable improvements in these metrics. For instance, Walmart utilized Lean and Six Sigma methodologies to optimize its supply chain. This resulted in significant cost savings and improved product availability, enhancing customer satisfaction.

Note: Continuous improvement requires active participation from leadership and employees. Encouraging teams to share ideas and test solutions fosters innovation and drives quality enhancements.

By focusing on quality improvement, businesses can build trust with customers and establish a competitive edge in their industries.

How Lean Thinking Reduces Waste

Understanding the Seven Types of Waste

Lean Thinking identifies seven types of waste that hinder efficiency and reduce value. These wastes occur across industries and processes, affecting productivity and customer satisfaction. By understanding these categories, organizations can target specific inefficiencies and implement strategies for improvement.

Defects/Mistakes: Poor quality work leads to wasted time and materials. Examples include software bugs or incorrect medication in healthcare.

Transportation: Unnecessary movement of items, such as inefficient delivery routes or moving hospital patients, adds no value.

Waiting: Idle time, whether for components in manufacturing or patients in waiting rooms, delays progress.

Motion: Excessive movement within a workspace, like searching for tools or navigating complex software, wastes energy.

Overproduction: Producing more than needed, such as unsold cars or redundant documents, ties up resources.

Over-processing: Performing tasks that do not add value, like entering the same data multiple times, consumes time unnecessarily.

Inventory: Storing excess products or supplies, such as unused equipment, increases costs without benefiting the customer.

Human Potential: Underutilizing employee skills and time on non-value-adding tasks limits innovation and productivity.

Organizations that address these wastes can streamline operations and enhance value delivery. For example, reducing defects not only minimizes scrap waste but also decreases resource consumption and rework costs.

Benefit Description | Outcome |

|---|---|

Fewer defects decrease the number of products that must be scrapped. | |

Fewer defects eliminate raw materials, energy, and waste associated with scrap. | Decreased resource consumption |

Fewer defects reduce energy, raw material, and waste used to fix defective products. | Lower rework costs |

Tip: Conducting regular waste audits helps teams identify inefficiencies and prioritize areas for improvement.

Tools and Techniques for Waste Elimination

Lean Thinking employs a variety of tools and techniques to eliminate waste and optimize processes. These methods empower teams to visualize inefficiencies, organize workflows, and foster continuous improvement.

Value Stream Mapping (VSM): Visualizes the flow of materials and information, pinpointing waste and opportunities for improvement.

5S Methodology: Enhances workplace organization by eliminating clutter and maintaining cleanliness, boosting safety and productivity.

Kanban System: Uses visual signals to manage inventory and workflow, reducing excess stock and improving efficiency.

Poka-Yoke: Prevents errors by designing processes that make mistakes impossible or easily detectable, ensuring higher quality.

Kaizen: Encourages incremental improvements from all employees, fostering a culture of innovation and waste reduction.

Just-in-Time (JIT): Produces goods precisely when needed, minimizing inventory and enhancing operational efficiency.

For example, implementing the 5S methodology in manufacturing can reduce motion waste by organizing tools and materials for easy access. Similarly, Kanban systems streamline inventory management, ensuring resources align with actual demand.

Note: Combining multiple Lean tools often yields the best results. Teams can use VSM to identify waste and then apply Kaizen principles to implement solutions.

Real-World Examples of Waste Reduction

Organizations across industries have successfully applied Lean Thinking to reduce waste and improve efficiency. These case studies highlight the transformative impact of Lean methodologies.

Starbucks: Streamlined layouts, standardized processes, and just-in-time inventory management reduced waste and enhanced efficiency. Continuous improvement and technology integration further optimized operations.

FedEx: Lean strategies in aircraft maintenance increased C-checks from 14 to 30 per year and reduced man-hours from 32,715 to 21,535. These changes improved productivity and lowered costs.

Columbus, OH Public Schools: Lean tools eliminated wasteful activities, enhancing the learning experience for students.

These examples demonstrate how Lean Thinking drives measurable results. By focusing on waste elimination, organizations can achieve higher efficiency, lower costs, and greater customer satisfaction.

Callout: Teams seeking to replicate these successes should start by identifying waste in their processes and selecting the most suitable Lean tools for their needs.

Practical Applications of Lean Thinking

Lean in Manufacturing

Lean Thinking revolutionizes manufacturing by optimizing processes and reducing waste. It emphasizes efficiency, quality, and customer satisfaction. Teams in manufacturing environments often adopt Lean tools like Just-In-Time (JIT) production and Value Stream Mapping to streamline workflows. These tools help identify bottlenecks and eliminate non-value-adding activities.

For example, manufacturers implementing Lean principles often see significant improvements in key performance indicators. The following table highlights the measurable benefits of Lean production:

Key Performance Indicator | Before Lean Implementation | After Lean Implementation |

|---|---|---|

Production Lead Time | 10 days | 6 days |

Defect Rates | 5% | 1% |

Overall Cost Savings | $500,000 | $750,000 |

These results demonstrate how Lean Thinking enhances productivity and reduces costs. Teams that adopt Lean principles also foster a culture of continuous improvement, ensuring long-term success.

Tip: Employee education on Lean principles is crucial for successful implementation. Training programs and open communication can help overcome resistance to change.

Lean in Healthcare

Healthcare systems benefit greatly from Lean Thinking. By focusing on patient needs and streamlining processes, hospitals and clinics can improve service delivery and reduce inefficiencies. Lean tools like 5S and Kaizen are commonly used to organize workspaces and encourage incremental improvements.

For instance, Lean Thinking has helped healthcare teams reduce patient wait times and enhance satisfaction. Systems that prioritize workflow efficiency often achieve better outcomes. Key performance indicators such as lead time, defect rates, and customer satisfaction provide valuable insights into the effectiveness of Lean practices.

Lean fosters continuous improvement across healthcare organizations.

Successful implementation requires careful planning and leadership support.

Metrics like productivity and quality help measure the impact of Lean initiatives.

Healthcare teams that embrace Lean principles often report higher employee engagement and improved patient care. These outcomes highlight the transformative potential of Lean Thinking in the healthcare sector.

Callout: Leadership plays a vital role in driving Lean adoption. Encouraging collaboration and recognizing employee contributions can motivate teams to embrace change.

Lean in Service Industries

Service industries, including retail and hospitality, leverage Lean Thinking to enhance customer experiences and operational efficiency. Teams use tools like Kanban systems and First Pass Yield (FPY) metrics to optimize workflows and reduce errors. These methods ensure that services align with customer expectations.

Industry benchmarks validate the improvements achieved through Lean principles. The table below outlines key metrics used to measure success in service industries:

Metric | Description |

|---|---|

Cycle Time | Total time taken to complete a specific service process, helping identify bottlenecks. |

First Pass Yield (FPY) | Percentage of services performed correctly the first time, indicating workflow efficiency. |

Customer Satisfaction | Feedback from surveys reflecting clients’ perceptions of service quality and efficiency. |

Employee Engagement | Metrics that assess employee satisfaction, influencing service quality and process execution. |

Organizations that adopt Lean Thinking often report higher customer satisfaction and lower operational costs. For example, retail teams using Lean tools have streamlined inventory management, ensuring products are available when customers need them.

Note: Continuous improvement is essential in service industries. Teams should regularly evaluate processes and implement changes to meet evolving customer demands.

Lean in Office and Knowledge Work

Lean Thinking transforms office and knowledge work by addressing inefficiencies and optimizing workflows. Unlike manufacturing, where physical processes dominate, office environments often deal with intangible tasks like data management, communication, and decision-making. Lean principles help streamline these processes, ensuring that every activity adds value to the organization and its customers.

One of the most significant challenges in office work is overproduction. Employees often create unnecessary reports or schedule redundant meetings. Reviewing report usage and conducting meeting audits can eliminate these inefficiencies. Similarly, waiting times, such as delays in approvals or slow system responses, hinder productivity. Establishing clear service level agreements (SLAs) and adopting automation tools can significantly reduce these bottlenecks.

Tip: Teams can use automation software to handle repetitive tasks, freeing employees to focus on more strategic activities.

Transportation waste, though less visible in office settings, occurs when digital hand-offs or data re-entry slow down workflows. Integrated software systems can reduce these inefficiencies by enabling seamless data sharing. Over-processing, such as overly complex approval processes, can also waste time. Simplifying these workflows and using standardized templates can enhance efficiency.

Type of Waste | Lean Solution |

|---|---|

Overproduction | Review report usage and audit meetings to eliminate unnecessary activities. |

Waiting | Use automation tools and set clear SLAs to reduce delays. |

Transportation | Implement integrated software systems to minimize digital hand-offs. |

Over-processing | Simplify workflows and use templates to avoid unnecessary complexity. |

Inventory waste in office work often takes the form of unread emails or backlogged tasks. Strategies like "inbox zero" and task management tools can help employees stay organized and prioritize effectively. Motion waste, such as searching for files or requiring physical signatures, can be reduced by organizing digital workspaces and adopting electronic signature tools.

Defects, including errors in documents or miscommunications, disrupt workflows and require rework. Quality checks and standardized templates can minimize these issues. Additionally, unutilized talent remains a common problem in office environments. Encouraging cross-training and creating opportunities for employees to contribute ideas can unlock their full potential.

Callout: Cross-training employees not only improves productivity but also fosters a more adaptable workforce.

Lean Thinking empowers office teams to identify and eliminate waste, leading to streamlined operations and higher employee satisfaction. By applying Lean principles, organizations can create a culture of continuous improvement, ensuring long-term success in knowledge-based work environments.

Fostering a Lean Culture

Leadership’s Role in Lean Thinking

Leadership plays a pivotal role in embedding Lean Thinking into an organization’s culture. Leaders set the tone by modeling behaviors that align with Lean principles. They prioritize transparency, accountability, and a commitment to continuous improvement. Effective leaders actively engage with teams to identify inefficiencies and implement solutions.

Successful Lean leaders focus on empowering employees. They provide the tools and training necessary for teams to contribute to process improvements. For example, leaders might organize workshops to teach Lean methodologies like Value Stream Mapping or Kaizen. By fostering collaboration, they create an environment where employees feel valued and motivated to participate in Lean initiatives.

Tip: Leaders should regularly communicate the benefits of Lean Thinking to employees. Clear messaging helps build trust and ensures alignment with organizational goals.

Building a Continuous Improvement Mindset

A continuous improvement mindset is essential for sustaining Lean Thinking. Organizations cultivate this mindset by encouraging employees to view challenges as opportunities for growth. Teams analyze processes, identify inefficiencies, and propose solutions. Small, incremental changes often lead to significant long-term benefits.

To build this mindset, organizations can implement structured improvement programs. For instance, daily stand-up meetings allow teams to discuss progress and share ideas for refinement. Metrics like defect rates and cycle times help measure the impact of these initiatives. Recognizing and celebrating successes reinforces the importance of continuous improvement.

Callout: Continuous improvement thrives in environments where experimentation is encouraged. Teams should feel safe to test new ideas without fear of failure.

Encouraging Employee Engagement

Employee engagement is a cornerstone of Lean Thinking. Engaged employees actively contribute to identifying and eliminating waste. Organizations foster engagement by involving employees in decision-making and improvement efforts. When employees feel their input matters, they become more invested in the success of Lean initiatives.

Strategies for boosting engagement include cross-training and open communication. Cross-training allows employees to develop new skills and understand different aspects of the workflow. Open communication ensures that employees can share feedback and collaborate effectively. For example, suggestion boxes or regular feedback sessions provide platforms for employees to voice their ideas.

Engagement Strategy | Benefit |

|---|---|

Cross-training | Enhances skill sets and promotes adaptability. |

Open communication | Builds trust and encourages collaboration. |

Recognition programs | Motivates employees by celebrating contributions to Lean initiatives. |

Note: Employee engagement improves when leaders actively listen and respond to feedback. Acknowledging contributions fosters a sense of ownership and pride among team members.

Overcoming Resistance to Change

Resistance to change often poses a significant challenge when implementing Lean Thinking. Employees may feel uncertain about new processes or fear losing their roles. Addressing these concerns requires thoughtful strategies that foster trust and collaboration.

Identify the Root Causes of Resistance

Understanding why employees resist change is the first step. Common reasons include fear of the unknown, lack of understanding, or perceived threats to job security. Leaders can conduct surveys, hold one-on-one discussions, or organize team meetings to uncover these concerns.

Tip: Active listening helps leaders identify specific issues and demonstrate empathy toward employees' perspectives.

Communicate the Benefits Clearly

Clear communication plays a vital role in overcoming resistance. Employees need to understand how Lean Thinking benefits them and the organization. Leaders should explain how the changes will improve workflows, reduce stress, and create opportunities for growth.

For example, a manufacturing team might learn that Lean principles will reduce repetitive tasks, allowing them to focus on more meaningful work. Sharing success stories from other teams or organizations can also inspire confidence.

Involve Employees in the Process

Engaging employees in the change process fosters a sense of ownership. Teams that participate in planning and decision-making are more likely to support new initiatives. Leaders can create cross-functional teams to identify inefficiencies and propose solutions.

Engagement Method | Outcome |

|---|---|

Cross-functional teams | Encourages collaboration and diverse perspectives. |

Brainstorming sessions | Generates innovative ideas and builds team cohesion. |

Pilot programs | Allows employees to test changes and provide feedback. |

Callout: Employees who feel valued and included are more likely to embrace change.

Provide Training and Support

Training equips employees with the skills needed to adapt to new processes. Workshops, online courses, and hands-on practice sessions can build confidence. Ongoing support, such as mentorship programs or help desks, ensures employees feel prepared to succeed.

Recognize and Reward Progress

Acknowledging efforts and celebrating milestones motivates employees to stay engaged. Recognition programs, such as "Employee of the Month" or team awards, highlight contributions to Lean initiatives. Rewards can include bonuses, certificates, or public appreciation during meetings.

Note: Positive reinforcement encourages a culture of continuous improvement.

By addressing resistance thoughtfully, organizations can create a supportive environment for Lean Thinking. These strategies empower employees to embrace change, driving long-term success.

Lean Thinking offers a transformative framework for organizations seeking to create value and reduce waste. Leaders play a pivotal role in its success by:

Coaching teams to foster continuous improvement.

Using metrics to measure progress and enhance performance.

This approach drives long-term success across multiple dimensions.

Impact Area | Description |

|---|---|

Lean practices help organizations eliminate waste and optimize processes, leading to better output with fewer resources. | |

Enhanced customer satisfaction | By focusing on customer needs, Lean Thinking ensures that all activities aim to meet or exceed customer expectations. |

Improved employee engagement | Lean empowers employees to actively participate in problem-solving, enhancing their morale and ownership of their work. |

Stronger competitive advantage | Lean organizations are more agile and responsive, providing them with a significant edge in the market. |

By adhering to its principles and fostering a Lean culture, organizations can achieve sustainable growth, innovation, and a competitive edge.

FAQ

What is Lean Thinking?

Lean Thinking is a methodology that focuses on creating value for customers while eliminating waste. It uses principles like defining value, mapping workflows, and continuous improvement to optimize processes and enhance efficiency.

How does Lean Thinking reduce waste?

Lean Thinking identifies seven types of waste, such as defects, overproduction, and waiting. Tools like Value Stream Mapping and Kaizen help teams pinpoint inefficiencies and implement strategies to eliminate them.

Can Lean Thinking be applied outside manufacturing?

Yes, Lean Thinking applies to various industries, including healthcare, retail, and office work. It optimizes workflows, reduces waste, and improves customer satisfaction across diverse sectors.

What are the benefits of Lean Thinking?

Lean Thinking improves efficiency, reduces costs, enhances product quality, and boosts customer satisfaction. It also fosters employee engagement and creates a culture of continuous improvement.

What tools are commonly used in Lean Thinking?

Popular tools include Value Stream Mapping, 5S methodology, Kanban systems, and Just-In-Time inventory management. These tools help visualize workflows, organize processes, and reduce waste.

How can organizations overcome resistance to Lean Thinking?

Organizations can address resistance by communicating benefits clearly, involving employees in decision-making, providing training, and recognizing contributions. These strategies foster trust and encourage adoption.

What is the role of leadership in Lean Thinking?

Leadership drives Lean Thinking by modeling behaviors, empowering teams, and fostering collaboration. Leaders provide tools, training, and support to ensure successful implementation.

How does Lean Thinking improve customer satisfaction?

Lean Thinking prioritizes understanding customer needs and delivering value-adding activities. By eliminating inefficiencies, organizations can provide faster, higher-quality products and services that align with customer expectations.