What Makes a Methodology for Process Improvement Effective

An effective methodology for process improvement delivers measurable results that drive real change. Companies achieve success when they reduce defects, eliminate waste, and boost customer satisfaction. Teams see progress when they use clear steps, apply analytical tools, and monitor key performance indicators like average response time and profit margin. Business management benefits from strategic approaches that involve employees and encourage strong communication. Sales growth and client retention depend on aligning processes with customer needs and quality standards. Knowledge of these criteria guides organizations toward sustainable improvements.

Key Takeaways

Effective process improvement methods deliver real, measurable results that help businesses reduce waste, lower costs, and improve customer satisfaction.

Clear and simple steps in a methodology help teams understand goals and work together smoothly, increasing the chance of success.

Adaptable methods allow organizations to adjust quickly to changes in customer needs, technology, and regulations, keeping them competitive.

Using data and metrics guides decisions, tracks progress, and proves the value of improvements, making results more reliable and sustainable.

Involving stakeholders and maintaining open communication builds trust, encourages teamwork, and reduces resistance to change.

Setting clear goals and measuring outcomes ensures improvements last and align with business priorities.

Piloting new methods on a small scale helps identify issues early, refine processes, and build confidence before full implementation.

Building a culture of continuous improvement with training, monitoring, and celebrating progress supports lasting success.

Effectiveness Defined

What Is Effectiveness

Effectiveness in process improvement means achieving real, measurable progress toward business goals. Leading business frameworks describe effectiveness as the ability to enhance process efficiency and quality in a systematic way. This approach leads to outcomes such as lower costs, fewer errors, higher productivity, and better customer satisfaction. Effective methodologies produce consistent and reliable results. They also create transparency, accountability, and agility, which help organizations respond to market changes and maintain a competitive edge.

Effectiveness stands out when a process improvement method aligns with customer value, uses data to guide decisions, and supports ongoing review and refinement. The method must also help the organization meet changing business goals and regulatory requirements.

The table below shows how popular frameworks define effectiveness and what they focus on:

Framework | Definition of Effectiveness in Process Improvement | Key Focus / Impact |

|---|---|---|

Lean | Delivering maximum value with minimum waste by eliminating non-value-adding activities. | Waste elimination, value stream mapping, streamlined processes. |

Six Sigma | Achieving high quality with minimal defects by reducing variability and defects using data-driven statistical tools. | Statistical process control, root cause analysis, near-perfect quality levels. |

Kaizen | Continuous incremental improvements involving all employees through small, manageable changes. | Regular feedback loops, small-scale workflow adjustments, everyone’s responsibility for improvement. |

Total Quality Management (TQM) | Integrating quality into every aspect of operations with customer satisfaction as a core goal. | Customer focus, total employee involvement, process-centered, quality-driven decisions. |

Theory of Constraints (ToC) | Focusing on identifying and addressing the most significant limiting factor to optimize overall system performance. | Identify and exploit constraints, subordinate other processes, elevate constraints for system-wide gain. |

PDCA (Plan-Do-Check-Act) | Iterative testing and refinement to ensure improvements work before full deployment. | Careful planning, small-scale testing, data analysis, risk reduction, broader implementation. |

Why It Matters

Organizations prioritize effectiveness because it leads to meaningful and lasting change. When a process improvement methodology works well, it helps teams reach business objectives and deliver better results. Effective methods drive higher efficiency, lower costs, and stronger productivity. They also improve employee engagement, product quality, and organizational agility.

A focus on effectiveness ensures that improvements last and become part of daily operations. Teams avoid quick fixes and instead build sustainable habits. A structured and systematic approach helps identify bottlenecks, streamline workflows, and remove unnecessary steps. This approach also supports compliance with industry standards and regulations.

Key measurable outcomes of effectiveness include:

Improved productivity through streamlined processes and automation.

Cost reduction by eliminating waste and optimizing resources.

Compliance with regulations and quality standards.

Reduced cycle times, which speed up business activities and improve customer satisfaction.

Measurable Outcome | Description |

|---|---|

Improved Productivity | Eliminating inefficiencies to increase output and enable teams to focus on valuable activities. |

Cost Reduction | Identifying bottlenecks and waste to optimize resources and reduce expenses. |

Compliance | Ensuring processes meet regulatory standards to avoid penalties and maintain quality. |

Reduced Cycle Times | Shortening delivery and task completion times to enhance customer satisfaction and competitiveness. |

Effective process improvement also relies on change management. This helps teams adopt new ways of working, reduces resistance, and ensures that improvements stick. By supporting employees and aligning changes with business goals, organizations turn process improvements into opportunities for growth.

Key Qualities

Clarity

Clarity stands as a foundation for any effective methodology for process improvement. Teams and systems achieve better results when everyone understands the steps, goals, and expectations. Clear communication helps teams avoid confusion and ensures that all members move in the same direction. Clients benefit because they receive consistent service and see improvements that match their needs.

Simple Steps

A strong methodology uses simple, well-defined steps. For example, Six Sigma’s DMAIC (Define, Measure, Analyze, Improve, Control) and PDCA (Plan, Do, Check, Act) both break down improvement into manageable actions. Lean’s 4Ps (Philosophy, Process, People, Problem Solving) also guide teams through a logical sequence. Simple steps help teams focus on what matters most and reduce the risk of errors.

Involving the right stakeholders and using reliable data maintain clarity.

Integration with business strategy and follow-up change management are critical for successful adoption.

Clear definition and communication of scope and goals prevent common pitfalls.

Easy to Follow

Easy-to-follow methods encourage higher adoption rates. When teams understand what to do and why, they feel more confident and motivated. For example, Kanban uses visual boards to show progress, making tasks and priorities clear for everyone. Agile frameworks use short cycles and regular feedback, which help teams stay on track.

Frequent monitoring and feedback support clarity in execution.

Positive attitudes and readiness for change increase adoption.

Clear expectations and ongoing feedback foster readiness for change.

Communication and feedback ensure understanding and alignment during adoption.

Leadership support and worker engagement are critical.

Clear communication gets everyone on board and explains why changes happen.

Unclear messaging hinders adoption.

Emphasizing the human aspect ensures everyone collaborates effectively.

Adaptability

Adaptability allows organizations to respond quickly to new challenges and opportunities. Teams that use adaptable methodologies can adjust their processes as client needs, technology, or regulations change. This flexibility supports long-term success and helps systems and teams remain competitive.

Fits Different Needs

A methodology for process improvement must fit different industries, team sizes, and project types. For example, Business Process Management (BPM) adapts to both manufacturing and service environments. Agile works well for software teams but also benefits marketing and operations. Adaptable methods allow teams to tailor steps and tools to their unique situations.

Adaptability in process improvement methodologies builds a culture of continuous evolution. Organizations that embrace ongoing refinement and learning from failures foster employee engagement, creativity, and ownership. This culture enhances agility, enabling companies to respond quickly to market changes, customer needs, and regulatory shifts. Leadership commitment, open communication, training, and recognition sustain this culture. Adaptability drives operational excellence, cost savings, innovation, and sustained competitive advantage.

Responds to Change

Adaptable methodologies help teams respond to unexpected changes. For example, Kaizen encourages small, frequent improvements, making it easier to adjust when problems arise. Agile and Lean both support rapid feedback and quick pivots. This approach keeps systems and teams resilient and ready for new demands.

Adaptability enables organizations to combine continuous improvement and process improvement approaches. Siemens achieved 30% efficiency gains by integrating these methodologies. Amazon uses process improvement for logistics challenges while maintaining continuous improvement for daily operations. This flexibility helps organizations align with strategic goals, respond to market changes, and foster efficiency, engagement, and resilience. Boeing reduced production defects by 50%, and Motorola increased employee satisfaction by 25% through continuous improvement programs.

Data-Driven

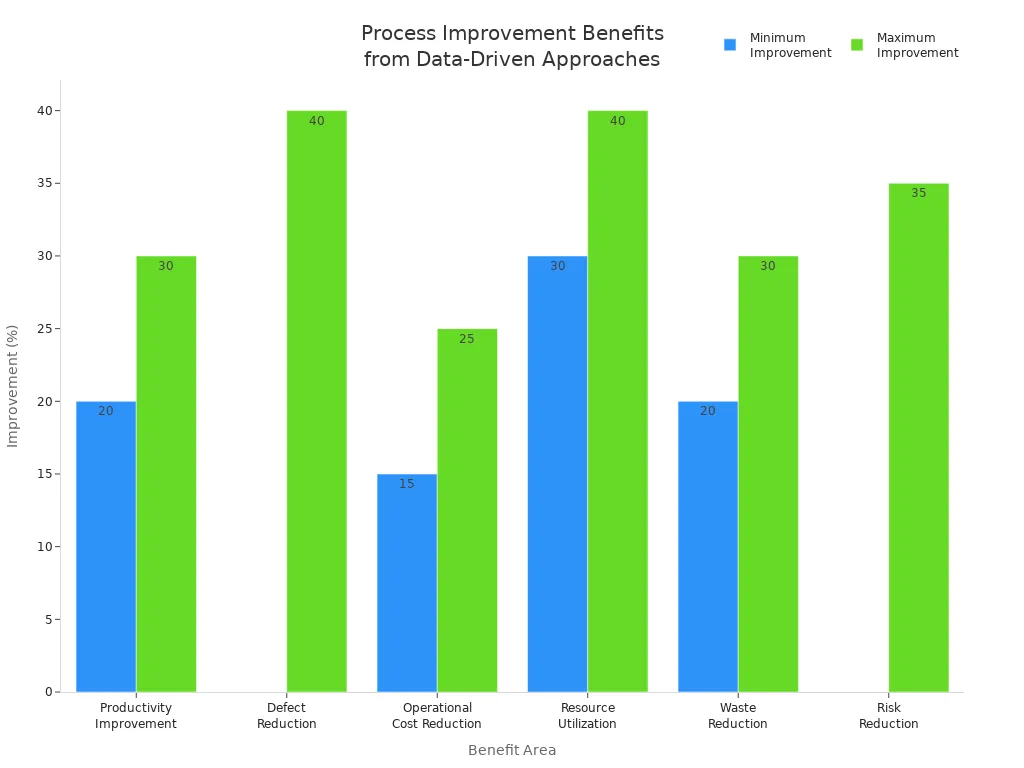

Data-driven methodologies use facts and metrics to guide decisions. Teams and systems that rely on data can identify problems, measure progress, and prove the value of their improvements. Clients benefit because they see real, measurable results.

Uses Metrics

Using metrics provides clarity and focus. Teams set clear goals that align with organizational strategy. Collecting accurate data helps identify inefficiencies and root causes. Analyzing these metrics pinpoints areas needing improvement and supports informed decisions. For example, Six Sigma uses statistical tools to measure defects and process variation. Lean tracks waste and cycle times to find improvement opportunities.

Tracks Progress

Tracking progress ensures that teams stay on course and make adjustments as needed. Data-driven decision making moves organizations beyond intuition. Analytics reveal patterns and trends that inform process improvements. By selecting key performance indicators and collecting robust data, companies gain insights into bottlenecks and inefficiencies. Applying analytics throughout the improvement cycle supports proactive optimization and fosters a culture of continuous improvement.

Benefit Area | Improvement Range |

|---|---|

Productivity Improvement | |

Defect Reduction | Up to 40% |

Operational Cost Reduction | 15-25% |

Resource Utilization | 30-40% |

Waste Reduction | 20-30% |

Risk Reduction | Up to 35% |

Teams and clients both benefit from data-driven approaches. Systems become more efficient, and organizations achieve measurable gains in quality, cost savings, and risk management. Integrating metrics with frameworks like Six Sigma DMAIC ensures that improvements are targeted and impactful.

Stakeholder Buy-In

Stakeholder buy-in plays a critical role in the success of any methodology for process improvement. When organizations involve stakeholders early and throughout the process, they gain valuable insights and foster a sense of ownership. This approach leads to better decisions and stronger commitment from everyone involved.

Team Involvement

Team involvement means more than just asking for approval. It requires active participation from employees, managers, and other key players. Organizations often use workshops, surveys, and advisory committees to gather feedback and encourage collaboration. These forums allow team members to share their expertise and concerns, which improves the quality of decisions.

Involving stakeholders builds trust and accountability. When people see that their input shapes the outcome, they feel more invested in the process. This sense of ownership reduces resistance to change and increases the likelihood of long-term success.

Successful companies identify stakeholders early, understand their needs, and keep them engaged. For example, Lean and Agile both emphasize team involvement through regular meetings and feedback sessions. Kanban uses visual boards that make progress visible to everyone, encouraging participation and transparency.

Communication

Clear and open communication keeps stakeholders informed and engaged. Organizations that provide regular updates and share both successes and challenges build trust and credibility. Transparency about how feedback influences decisions helps maintain enthusiasm and support.

Regular status updates keep everyone aligned.

Public recognition of achievements boosts morale.

Continuous feedback improves the process and adapts to new challenges.

Sharing success stories highlights the value of the initiative.

A methodology for process improvement that prioritizes communication ensures that all voices are heard. This approach aligns stakeholder interests with organizational goals and secures the resources needed for success. Celebrating milestones and recognizing contributions help maintain momentum and commitment.

Measurable Results

Measurable results set effective process improvement apart from less successful efforts. Organizations that define clear goals and track progress can prove the value of their initiatives. This focus on measurement supports continuous improvement and long-term sustainability.

Clear Goals

Clear goals give teams direction and purpose. They help everyone understand what success looks like and how to achieve it. Frameworks like Six Sigma and PDCA require teams to set specific, measurable objectives before starting any improvement effort.

Setting clear goals allows organizations to align their efforts with business priorities. Teams can focus on what matters most and avoid wasting time on activities that do not add value.

Lean and TQM also stress the importance of clear goals. These methodologies use key performance indicators (KPIs) to track progress and guide decision-making. When teams know what they are working toward, they stay motivated and accountable.

Sustainable Impact

Sustainable impact means that improvements last over time and continue to deliver value. Organizations achieve this by embedding measurement into every stage of the process. The SusQI framework, for example, links measurable outcomes—such as resource use and system-wide effects—to sustainability. This approach ensures that process improvements do not fade away but become part of daily operations.

Research shows that using standardized frameworks and KPIs helps organizations track progress and evaluate effectiveness. Measuring sustainability performance allows companies to connect short-term wins with long-term goals. This practice supports continuous improvement and helps organizations adapt to changing needs.

A methodology for process improvement that delivers sustainable impact uses data to guide decisions and measure success. By focusing on measurable results, organizations can demonstrate value, secure stakeholder support, and build a culture of ongoing improvement.

Methodology Examples

Six Sigma

Six Sigma stands out as a disciplined, data-driven methodology for process improvement. Organizations use Six Sigma to reduce process variation and minimize defects. The approach relies on the DMAIC cycle: Define, Measure, Analyze, Improve, and Control. Teams start by defining the problem and project goals. They measure current performance, analyze data to find root causes, improve the process, and control changes to sustain results.

Six Sigma emphasizes customer focus and uses statistical methods to guide decisions. Management support and specialized roles, such as Green Belts and Black Belts, provide expertise and leadership. Teams map the value chain, eliminate defects, and involve stakeholders in collaborative problem solving. The system adapts to changes and maintains improvements over time.

Contribution to Effectiveness | |

|---|---|

Statistical Controls & Data-Driven Decision Making | Accurate controls and data ensure processes meet defined norms. |

DMAIC Cycle | Guides systematic problem solving and improvement. |

Leadership Support | Top management provides resources and focus. |

Project and Objective-Based Focus | Projects have clear goals and measurable outcomes. |

Specialized Roles and Training | Expertise and leadership in applying Six Sigma tools. |

Reducing Process Variation | Minimizes defects and improves quality. |

Sustaining Improvements | Control mechanisms maintain gains. |

Flexibility and Stakeholder Involvement | Adapts to changes and involves stakeholders. |

Six Sigma delivers enhanced quality control, increased efficiency, cost reduction, and higher customer satisfaction. Teams set clear goals and assemble the right experts to ensure effective collaboration.

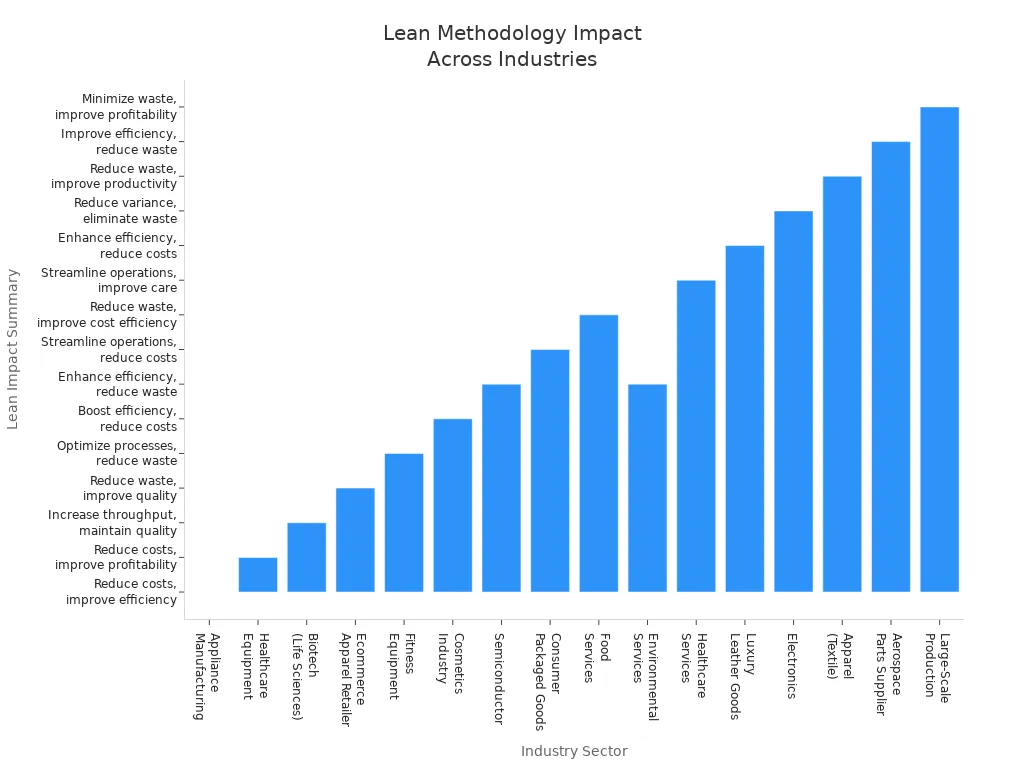

Lean

Lean methodology targets waste reduction and process efficiency. Organizations across industries use Lean to streamline workflows, lower costs, and improve quality. Lean principles focus on identifying and eliminating non-value-added activities. Teams map processes, refine steps, and optimize resource use.

Lean has proven effective in manufacturing, healthcare, retail, and more. Companies address challenges such as high costs, production inefficiencies, inventory issues, and quality problems. Lean strategies help organizations reduce cycle times, minimize inventory, and boost operational agility.

Lean fosters cultural change and leadership engagement. Teams integrate Lean with other systems, such as ERP and circular economy principles, to sustain benefits. The methodology for process improvement encourages employee involvement and continuous learning. Lean’s impact includes improved cash flow, reduced defects, and enhanced customer satisfaction.

TQM

Total Quality Management (TQM) focuses on integrating quality into every aspect of operations. Organizations use TQM to empower employees, foster continuous improvement, and deliver superior products and services. TQM emphasizes leadership, education, and customer focus.

Research shows that TQM improves project management, employee engagement, and competitive positioning. Teams plan, execute, and monitor projects more effectively. TQM leads to higher product and service quality, fewer defects, and greater customer satisfaction. Organizations foster innovation, strengthen supplier relationships, and streamline processes.

TQM also enhances communication and coordination across all levels. Companies gain market share and improve brand reputation by committing to quality. TQM supports data-driven decision-making and compliance with regulatory standards. Integration with technologies like AI and automation helps predict and prevent quality issues. Real-time monitoring enables proactive improvements and supports sustainability and ethical practices.

TQM creates a culture where everyone contributes to quality. Employees feel empowered, and organizations respond quickly to changing demands.

PDCA

The PDCA cycle—Plan, Do, Check, Act—offers a structured, repeatable approach for continuous improvement. Organizations use PDCA to solve problems, refine processes, and adapt to changing needs. The cycle begins with planning, where teams set objectives, identify issues, and create action plans. During the Do phase, they implement changes and collect data. The Check phase involves evaluating results by comparing data to goals. In the Act phase, teams standardize successful changes or make further adjustments if needed.

PDCA supports operational excellence by enabling structured problem-solving and continuous adaptation.

Many industries rely on PDCA for its versatility. For example, aerospace companies reduce aircraft downtime by identifying causes, adopting preventive maintenance, and training staff. Manufacturing plants use PDCA to improve production quality, while restaurants apply it to reduce wait times and enhance service. Companies like Toyota, Nestlé, Amazon, and Microsoft use PDCA to maintain high standards and adapt quickly.

PDCA fosters a culture of problem solvers and critical thinkers.

The cycle encourages rigorous testing of ideas on a small scale.

Data-driven adjustments and reassessments ensure ongoing learning.

Successful improvements become standardized practices.

PDCA’s iterative nature helps organizations maintain competitiveness and operational excellence. Teams learn from each cycle, making continuous improvement a habit rather than a one-time event.

Kaizen

Kaizen stands as a philosophy that emphasizes continuous, incremental improvements in daily operations. This approach encourages everyone—from frontline workers to managers—to contribute ideas for making processes better. Kaizen builds teamwork and collaboration, empowering employees to take ownership of improvements.

Kaizen uses structured tools like the PDCA cycle, 5S workplace organization, Gemba walks, and the 5 Whys technique.

Employees regularly review, adapt, and standardize improvements to sustain long-term change.

The method creates a safe environment for experimentation, viewing mistakes as opportunities for growth.

By involving employees in co-creating solutions, Kaizen reduces resistance to change.

Kaizen embeds continuous improvement into the culture. Employees receive training and resources to identify and solve problems at the source. This approach boosts engagement, morale, and creativity. Organizations that practice Kaizen see sustainable growth and operational excellence because improvement becomes a shared responsibility.

Kanban

Kanban methodology improves workflow by making tasks visible and manageable. Teams use Kanban boards to track work as it moves through different stages. This visual approach helps everyone understand priorities, spot bottlenecks, and keep projects on track.

Aspect | Benefit |

|---|---|

Visibility & Transparency | Kanban boards make tasks and progress clear for all team members. |

Work-in-Progress Limits | Limiting tasks in progress helps teams focus and finish work faster. |

Faster Turnaround Times | Companies report quicker manufacturing and delivery, reducing costs. |

Predictability | Kanban helps teams plan resources and anticipate risks. |

Flexibility | The system adapts to changes and supports continuous improvement. |

Waste Reduction | Kanban reduces unnecessary work, improving efficiency. |

Productivity Gains | Teams often see a 30-50% reduction in lead time and a 25-40% increase in throughput. |

Employee Engagement | Visibility and reduced context switching boost engagement by up to 60%. |

Kanban’s pull system ensures teams only start new work when capacity allows, preventing overload. Metrics from Kanban boards help teams measure workflow and identify areas for improvement. Online Kanban tools enhance collaboration, especially for remote teams. By focusing on visibility, flow, and incremental change, Kanban supports adaptability and sustained productivity.

BPM

Business Process Management (BPM) provides a structured approach for organizations to analyze, design, execute, monitor, and optimize their processes. Teams use BPM to map out workflows, automate repetitive tasks, and ensure every step adds value. This methodology helps systems and teams work more efficiently and deliver consistent results to clients.

BPM stands out for its ability to simplify complex processes. For example, employee onboarding often involves many departments. BPM automates approvals and centralizes tasks, which reduces errors and saves time. Teams can scale processes easily as the organization grows or changes.

The following table highlights key benefits organizations report after adopting BPM:

Benefit | Description |

|---|---|

Improved customer satisfaction | BPM maps and optimizes processes from the customer's perspective, building loyalty. |

Ensured policy compliance | Structured controls help meet regulations and reduce legal risks. |

More accurate data | Automation lowers manual errors and secures data access. |

Easier scalability | Processes can be modified to handle growth and complexity. |

Digital transformation | Integrates new technologies and automation for innovation. |

Reduced license overhead | Identifies redundant software, cutting costs. |

Identified strengths and skill gaps | BPM data reveals workforce skills and gaps for targeted training. |

BPM supports continuous improvement by allowing teams to adapt quickly to new business needs. Real-time monitoring gives managers transparency and helps them make informed decisions. Clients benefit from faster, more reliable service. BPM also encourages collaboration by using low-code platforms, making it easier for non-technical staff to participate in process design.

BPM enables organizations to standardize processes, improve quality, and reduce costs. Teams gain the flexibility to innovate and respond to market changes, while clients receive better service and support.

Agile

Agile methodology focuses on flexibility, collaboration, and rapid response to change. Teams break work into short cycles called sprints. Each sprint ends with a review and a retrospective, where teams discuss what worked and what needs improvement. This cycle supports continuous learning and quick adaptation.

Agile encourages teams to experiment and try new ideas. Leaders model transparency and empower teams to make decisions. Cross-functional teams work together, using tools that support communication and problem-solving. Agile practices, such as daily stand-ups and sprint reviews, keep everyone aligned and focused on delivering value.

Teams use regular retrospectives to identify improvements and take action.

Agile promotes a culture where failure is seen as a learning opportunity.

Customer feedback is gathered throughout development, ensuring the final product meets user needs.

Agile works well in environments with high uncertainty or frequent changes.

Agile’s iterative approach helps organizations respond quickly to new requirements. Teams can adjust priorities and processes without waiting for long project cycles to finish. Clients benefit from faster delivery and solutions that better match their needs.

Agile methodology enhances adaptability and responsiveness. Teams and clients see improved outcomes because they can react to feedback and changing conditions in real time.

RAPID

RAPID is a decision-making framework that clarifies roles and responsibilities in complex processes. The acronym stands for Recommend, Agree, Perform, Input, and Decide. Each role has a specific function, which increases transparency and accountability.

Teams use RAPID to involve multiple experts in decision-making. This approach leads to better risk planning and more balanced decisions. By defining who recommends actions, who must agree, who provides input, who performs the work, and who makes the final decision, RAPID reduces confusion and conflict.

RAPID improves communication and collaboration among team members.

The framework works well for high-stakes decisions that require input from many stakeholders.

Organizations use RAPID to streamline processes and ensure everyone understands their responsibilities.

Tools like ProofHub help teams track tasks and monitor progress during RAPID implementation.

RAPID supports efficient, unbiased decision-making. Teams achieve better outcomes because everyone knows their role, and decisions are made with input from the right people.

5 Whys

The 5 Whys technique offers a simple yet powerful approach for uncovering the root cause of problems in process improvement. Teams use this method by asking "why" repeatedly—usually five times—to move beyond surface symptoms and reach the underlying issue. This technique stands out for its clarity and ease of use. People from different backgrounds can apply it without needing advanced statistical tools or complex training.

The process begins with a clear definition of the problem. Teams form with members who understand the situation and observe actual conditions. They avoid making assumptions and focus on facts. For example, in manufacturing, a team might notice frequent production delays. By asking "why" several times, they discover that outdated maintenance schedules cause the problem. In healthcare, unclear labeling instructions may lead to medication errors. The 5 Whys method helps teams identify these systemic issues rather than blaming individuals.

The 5 Whys technique emphasizes a "go and see" philosophy. Teams investigate problems directly at the source, which leads to more accurate findings and effective solutions.

The method supports adaptability because teams can use it in many industries, such as manufacturing, customer service, and healthcare. It works best for straightforward or moderately complex problems with a single root cause. For more complicated issues, other tools like Fishbone diagrams or Six Sigma may be more suitable.

Stakeholder buy-in increases when teams involve diverse members in the questioning process. Each person brings a unique perspective, which helps uncover the real cause of the problem. Teams document each "why" and its answer, creating a clear record of their investigation. This transparency builds trust and accountability.

The 5 Whys technique also delivers measurable results. After identifying the root cause, teams develop corrective actions that are specific, measurable, achievable, relevant, and time-bound (SMART). For instance, if outdated software causes delivery delays in customer service, the team can set a goal to upgrade the system within a set timeframe.

Key Quality | How 5 Whys Embodies It |

|---|---|

Clarity | Simple steps and clear documentation |

Adaptability | Used across industries and problems |

Stakeholder Buy-In | Involves diverse team perspectives |

Measurable Results | Leads to SMART corrective actions |

The 5 Whys technique avoids quick fixes and focuses on preventing recurrence. By targeting the root cause, teams ensure that improvements last. This method encourages continuous learning and supports a culture of problem-solving. Teams who use 5 Whys build stronger processes and deliver better outcomes for their organizations.

Common Pitfalls

Over-Complexity

Many organizations fall into the trap of over-complicating their process improvement methodologies. When teams design systems with too many steps, tools, or requirements, they create confusion and frustration. A case study from a business performance initiative showed that an overly complex ERP system overhaul drained millions of dollars, increased user frustration, and produced convoluted reporting. The project failed to address core process issues and missed savings opportunities with legacy systems. Over-complexity often leads to misaligned priorities, wasted resources, and missed goals.

Expert analysis reveals that complex projects increase business risks and financial costs. They strain organizational capacity and cause delays. Scope creep becomes more likely, and teams lose sight of the original objectives. To avoid these problems, organizations should prioritize manageable complexity, shorter timelines, and clear value. Structured prioritization, risk assessment, and staged implementation help reduce the negative impact of complexity.

Research in construction projects supports this view. As complexity rises, the chance of project success drops. Teams must address organizational, human, and technical factors early in planning. Simple, focused methodologies improve outcomes and help teams achieve their goals.

Inflexibility

Rigid process improvement methods can block progress and reduce morale. When organizations use inflexible systems, employees feel confined to narrow roles. This limits adaptability and increases reliance on temporary hires, raising costs. A claims processing company experienced these issues with rigid roles and poorly designed performance measures. Staff felt demotivated, and customer service suffered. By switching to multi-skilled training and flexible metrics, the company reduced work-in-progress, sped up claim resolution, and improved satisfaction.

Inflexibility causes several problems:

Limited workforce versatility

Prolonged onboarding

Increased downtime during transitions

Delays in technology adoption

Overdependence on external consultants

Poor collaboration between departments

Inventory mismanagement

Inadequate knowledge transfer

These issues lower productivity, increase costs, and erode competitiveness. Flexible, continuous improvement approaches help organizations adapt, share knowledge, and respond to change.

Poor Engagement

Stakeholder engagement plays a critical role in process improvement success. Poor engagement leads to project failures, wasted resources, and missed deadlines. Data shows that organizations lose nearly 10% of every dollar due to poor project performance. About one-third of projects do not meet their goals, and many run late or over budget.

Managing stakeholder expectations and interests is essential. Effective engagement secures buy-in, aligns expectations, and ensures proper resource allocation. Lack of commitment increases risk and resistance. Continuous feedback from stakeholders improves the chance that project outcomes meet end-user needs. Early and ongoing involvement, starting from project charter approval, helps eliminate roadblocks and surprises.

Poor engagement causes misunderstandings about requirements and priorities.

Lack of early consultation leads to conflicting expectations and frequent scope changes.

Insufficient communication results in resistance and project delays.

Proactive stakeholder management, including regular meetings and tailored engagement strategies, helps bridge gaps and realign objectives. Formal change management and stakeholder analysis improve project delivery and build trust.

No Metrics

A lack of metrics stands as one of the most common reasons process improvement efforts fail. Metrics serve as the foundation for tracking progress, measuring success, and guiding future decisions. When organizations do not use clear and relevant metrics, they lose the ability to see if their changes make a real difference. Teams may work hard to improve processes, but without data, they cannot prove results or identify areas that need more attention.

Metrics help organizations set goals, monitor performance, and adjust strategies. Visual tools like run charts and dashboards allow teams to see trends over time. These tools make it easier to spot problems early and celebrate wins. When teams skip this step, they risk missing critical information. They may continue with ineffective changes or overlook opportunities for further improvement.

"What gets measured gets managed." This saying highlights the importance of tracking key indicators. Without measurement, teams cannot manage or improve what they do not understand.

Organizations that ignore metrics face several risks:

They may invest time and resources in changes that do not lead to meaningful improvements.

Teams lack an evidence-based way to identify inefficiencies or set realistic goals.

There is no objective method to validate efforts, detect underperformance, or adjust strategies.

Resources might be wasted on changes that bring little operational benefit.

Poor or missing metrics can result in misguided efforts and failure to achieve business goals.

A feasible number of measures is essential. Too many metrics can cause information overload, while too few may miss important aspects of improvement. Teams should select metrics that align with their goals and are easy to track. For example, a manufacturing team might measure defect rates, while a customer service team tracks response times.

The absence of metrics also affects long-term sustainability. Without regular tracking, improvements may fade over time. Teams lose momentum, and old habits return. Metrics provide a way to keep everyone focused and accountable.

Problem Without Metrics | Impact on Process Improvement |

|---|---|

No way to track progress | Teams cannot see if changes work |

Lack of accountability | Hard to assign responsibility for outcomes |

Missed opportunities | Teams overlook areas needing improvement |

Difficulty sustaining gains | Improvements may not last over time |

Teams that use metrics create a culture of continuous improvement. They learn from data, celebrate progress, and make informed decisions. Metrics turn process improvement from guesswork into a science, helping organizations achieve lasting success.

Choosing a Methodology for Process Improvement

Assess Needs

Organizations must start by understanding their unique challenges before selecting a methodology for process improvement. They identify the process that needs improvement, focusing on areas with the greatest impact. Teams collect data on current performance, such as duration, costs, error rates, and customer feedback. This information helps them see where problems exist.

A clear goal guides the improvement effort. Teams set SMART goals—Specific, Measurable, Achievable, Relevant, and Time-bound. These goals define what success looks like and keep everyone focused. Involving members from different departments ensures that all perspectives are considered. Each person understands their role and responsibility.

Companies also review their resources and expertise. Some methodologies require special training or knowledge. If needed, organizations seek advice from process improvement experts. These steps help align needs, capabilities, and goals.

Tip: Use flowcharts to outline the process from both business and customer viewpoints. This visual tool helps teams understand each step, trigger, and output.

Steps to Assess Needs:

Identify the process to improve and describe it from business and customer perspectives.

Gather data on current performance, focusing on key metrics.

Analyze data to find bottlenecks and inefficiencies.

Set SMART goals for improvement.

Involve team members from all affected areas.

Review resources and expertise, seeking expert advice if needed.

Match to Goals

Selecting the right methodology for process improvement means matching it to the organization’s goals. Teams define strategic objectives and set SMART metrics that align with the business strategy. They assess current processes using tools like Value Stream Mapping and root cause analysis. This helps them spot gaps and opportunities.

Organizations prioritize projects based on their impact, feasibility, cost, risk, and customer effect. Stakeholder involvement ensures buy-in and support. Teams choose a methodology that fits their needs, such as Lean for waste reduction or Six Sigma for quality control.

Structured approaches like DMAIC or PDCA help teams implement and monitor projects. Clear communication of roles and responsibilities keeps everyone aligned. Continuous tracking of metrics ensures that the methodology supports business goals and adapts as needed.

Note: Regularly review progress and adjust strategies to maintain alignment with changing business objectives.

Steps to Match to Goals:

Assess current processes using mapping and analysis tools.

Prioritize projects based on impact and feasibility.

Involve stakeholders in decision-making.

Select a methodology that fits the organization’s needs.

Implement and monitor using structured frameworks.

Involve Teams

Team involvement is essential for successful process improvement. Organizations include the entire team in brainstorming and solution development. This approach ensures that improvements are practical and gain support from those who will use them.

Team members provide input and feedback on existing processes. Their engagement helps identify real problems and workable solutions. Companies foster a collaborative atmosphere by acknowledging contributions and offering training. Including the team in improvement discussions builds trust and motivation.

Effective communication keeps everyone informed about changes and expectations. Workforce management tools help assign roles, monitor timelines, and facilitate communication. Clear standards and procedures sustain improvements and allow for regular review.

Teams that work together create lasting change. Collaboration leads to better ideas and stronger results.

Best Practices for Team Involvement:

Encourage input and feedback from all team members.

Foster collaboration by recognizing contributions.

Offer training and include everyone in brainstorming sessions.

Communicate changes clearly and regularly.

Use management tools to organize tasks and track progress.

Establish standards and review effectiveness often.

Pilot and Measure

Piloting a process improvement methodology helps organizations test ideas before full-scale implementation. This approach reduces risk and builds confidence in the chosen method. Teams learn what works and what needs adjustment by running a controlled trial.

Steps to Pilot and Measure Effectively:

Set Clear Goals and Objectives

Teams begin by defining what they want to achieve. Goals should be specific and measurable. For example, a team may aim to reduce defect rates by 20% or cut cycle times by two days.Plan the Pilot Carefully

A detailed plan outlines the scope, timeline, and resources. Teams select a process area that represents real production conditions. Using the same equipment, materials, and staff ensures results reflect actual operations.Engage the Right People

Cross-functional teams bring together different skills and viewpoints. Involving stakeholders, such as customers and suppliers, provides valuable feedback and increases buy-in.Define Key Performance Indicators (KPIs)

Teams choose metrics that align with their goals. Common KPIs include cycle time, defect rate, and production yield. These indicators help measure progress and success.Execute the Pilot

The team implements the new process on a small scale. They monitor each step closely, following strict quality control and inspection protocols. This helps catch problems early.Collect and Document Data

Teams gather data on all relevant parameters, including any deviations or issues. Detailed records support thorough analysis later.Analyze Results and Identify Issues

Teams compare pilot data to established goals. If results fall short, they conduct root cause analysis to find out why. This step uncovers bottlenecks or unexpected challenges.Refine and Adjust

Insights from the pilot guide process adjustments. Teams make corrections and update their plans. Flexibility during this phase leads to better outcomes.Gather Feedback from Stakeholders

Teams seek input from everyone involved. Open communication helps identify further improvements and builds support for the next steps.Prepare for Full Implementation

After refining the process, teams develop a plan to scale up. They communicate changes, provide training, and ensure everyone is ready for the transition.

Tip: Treat every pilot as a learning opportunity. Encourage teams to experiment, make adjustments, and share lessons learned. This mindset supports a culture of continuous improvement and innovation.

Organizations that pilot and measure new methodologies gain valuable insights before making large-scale changes. They minimize disruptions, build stakeholder confidence, and set the stage for lasting success. Continuous monitoring and open feedback keep the process on track and ensure improvements deliver real value.

Implementation Tips

Build Culture

A strong culture supports process improvement. Leaders set the tone by modeling desired behaviors. They show commitment to improvement by recognizing achievements and encouraging open communication. Teams thrive when they feel safe to share ideas and learn from mistakes.

Tip: Leaders can hold regular meetings to discuss progress and celebrate small wins. This builds trust and keeps everyone motivated.

Organizations that value continuous improvement create spaces for feedback. They encourage employees to suggest changes and reward creative solutions. A positive culture helps teams adapt to new methods and sustain improvements over time.

Key actions to build culture:

Recognize and celebrate progress.

Encourage open communication.

Support learning from mistakes.

Involve everyone in improvement efforts.

Train Teams

Training equips teams with the skills they need for success. Effective training covers both the chosen methodology and the tools required. Teams learn how to collect data, analyze results, and apply new processes.

A mix of classroom sessions, hands-on workshops, and online resources works best. Teams benefit from real-world examples and practice exercises. Leaders should provide ongoing support and answer questions as they arise.

Note: Training should match the needs of each team. Some may need advanced skills, while others need basic instruction.

A well-trained team feels confident and ready to tackle challenges. Training also helps reduce errors and ensures everyone follows the same steps.

Training checklist:

Provide clear instructions and resources.

Use real examples for practice.

Offer support and answer questions.

Update training as processes change.

Monitor and Adapt

Monitoring ensures that improvements deliver results. Teams track key metrics and review progress regularly. They use dashboards or charts to visualize data and spot trends.

When teams notice problems, they act quickly to adjust. Adaptation keeps processes effective as conditions change. Regular reviews help teams learn what works and what needs improvement.

Teams that monitor and adapt stay ahead of challenges. They make small changes before problems grow.

A simple table can help teams track progress:

Metric | Target Value | Current Value | Status |

|---|---|---|---|

Defect Rate | < 2% | 1.8% | On Track |

Cycle Time | 5 days | 6 days | Needs Work |

Customer Rating | 4.5/5 | 4.6/5 | Exceeds |

Teams that monitor and adapt build a habit of continuous improvement. This approach helps organizations achieve lasting success.

Action Steps

Recap Qualities

Effective process improvement methodologies share several important qualities. These qualities help organizations achieve real, lasting results. The following table summarizes the key qualities discussed in this blog:

Quality | Description |

|---|---|

Clarity | Clear steps and easy-to-understand instructions |

Adaptability | Ability to fit different needs and respond to change |

Data-Driven | Use of metrics and tracking to guide decisions |

Stakeholder Buy-In | Involvement and communication with all team members |

Measurable Results | Clear goals and sustainable impact |

Teams that focus on these qualities see better outcomes. They avoid confusion, adapt to new challenges, and measure their progress. Leaders who support these qualities build a strong foundation for improvement.

Tip: Review each quality before starting a new process improvement project. This helps teams stay focused and organized.

Next Steps

Organizations can take several practical steps to put these ideas into action:

Assess Current Processes

Teams should map out their current workflows. They can use flowcharts or diagrams to spot bottlenecks and waste.Set Clear Goals

Leaders need to define what success looks like. Goals should be specific, measurable, and realistic.Choose the Right Methodology

Teams should match the methodology to their needs. For example, Lean works well for waste reduction, while Six Sigma targets quality control.Involve Stakeholders Early

Teams should invite input from everyone affected by the process. Early involvement builds trust and support.Pilot and Measure

Teams should test changes on a small scale. They need to collect data and compare results to their goals.Train and Support Teams

Leaders should provide training and resources. Teams need the right skills to succeed.Monitor Progress and Adapt

Teams should track key metrics. They must review results often and make adjustments as needed.

Note: Continuous improvement is a journey, not a one-time event. Teams should celebrate small wins and learn from setbacks.

By following these steps, organizations can build a culture of improvement. They will see better results, higher engagement, and lasting success.

Effective process improvement relies on clarity, adaptability, data-driven decisions, stakeholder buy-in, and measurable results. Organizations achieve success when they define clear goals, assess pain points, and set targets for progress. They select the right methodology, pilot changes, and monitor key metrics. Teams engage employees, streamline workflows, and standardize best practices. Sustaining improvements requires embedding changes into company culture. Those seeking further guidance or support can reach out to us for more information.

FAQ

What is the first step in process improvement?

Teams should start by mapping the current process. They identify each step, gather data, and look for bottlenecks. This foundation helps them understand where to focus improvement efforts.

How often should organizations review their processes?

Organizations benefit from regular reviews. Many experts recommend quarterly or annual assessments. Frequent reviews help teams catch problems early and adapt to changes quickly.

Can small businesses use these methodologies?

Yes, small businesses can apply process improvement methods. They can start with simple tools like 5 Whys or PDCA. These approaches require minimal resources and deliver measurable results.

What role does leadership play in process improvement?

Leaders set the vision and provide support. They encourage team involvement, allocate resources, and celebrate progress. Strong leadership builds a culture of continuous improvement.

How do teams measure success in process improvement?

Teams use key performance indicators (KPIs) such as defect rates, cycle times, and customer satisfaction scores. Tracking these metrics shows if changes deliver real benefits.

Is training necessary for process improvement?

Training equips teams with the right skills. It ensures everyone understands the chosen methodology and tools. Well-trained teams make fewer mistakes and achieve better results.