Understanding Six Sigma Methodology in 2025

Six sigma methodology in 2025 stands as a data-driven system for reducing defects and improving processes across industries such as Sales and Business Management. Teams use six sigma to achieve quality levels below 3.4 defects per million opportunities, driving customer satisfaction and efficiency. Companies rely on statistical tools like control charts and Pareto charts to monitor progress. Systems and teams that apply this Knowledge see improved decision-making and cost savings. The following table highlights six sigma’s measurable benefits:

Benefit | Description |

|---|---|

Higher Customer Satisfaction | Meets or exceeds customer expectations with quality improvements |

Increased Efficiency | Streamlines processes and reduces costs |

Enhanced Process Control | Ensures quality and reliability |

Key Takeaways

Six Sigma helps teams reduce defects and improve processes using data and statistics.

The DMAIC process guides improvement through Define, Measure, Analyze, Improve, and Control steps.

Six Sigma focuses on meeting customer needs and increasing satisfaction with quality results.

Combining Six Sigma with Lean creates Lean Six Sigma, which reduces waste and defects together.

Certification levels from White Belt to Master Black Belt build skills and open career opportunities.

Six Sigma delivers cost savings, faster workflows, and higher efficiency across many industries.

Successful Six Sigma projects rely on clear goals, reliable data, teamwork, and ongoing monitoring.

Online training and tools make Six Sigma learning accessible and practical for all skill levels.

Six Sigma Methodology Overview

What Is Six Sigma?

Six sigma is a data-driven methodology that organizations use to reduce defects and control process variation. This quality control method focuses on improving processes by identifying and eliminating the causes of errors. Teams and systems apply six sigma to achieve a process quality level of no more than 3.4 defects per million opportunities. This approach uses statistical tools and structured frameworks to guide process improvement projects. Six sigma serves as both a process improvement strategy and a statistical concept, making it a powerful tool for quality management.

Six sigma methodology helps systems and teams make better decisions by relying on data-driven quality management. This approach ensures that improvements are measurable and sustainable.

Many industries have adopted six sigma, including manufacturing, healthcare, finance, and government. Companies such as Motorola, Boeing, and Microsoft have used six sigma to achieve significant cost savings and product improvements. For example, Motorola saved $17 billion over 20 years by using six sigma to improve quality control. Boeing resolved manufacturing defects in engine air fans, and Microsoft used six sigma tools to develop successful products like Windows CE.

Key Principles

Six sigma methodology relies on several key principles that guide systems and teams toward successful process improvement:

Focus on the customer: Teams identify what customers value most and design processes to meet those needs.

Use data and statistical analysis: Six sigma depends on data-driven decision making to measure, analyze, and improve process performance.

Reduce defects and process variation: The goal is to minimize errors and create consistent, reliable outcomes.

Involve everyone: Six sigma encourages participation from all levels of an organization, from leadership to front-line employees.

Sustain improvements: Teams use control methods to maintain gains and prevent problems from returning.

Six sigma uses the DMAIC framework—Define, Measure, Analyze, Improve, Control—to structure projects. Each phase involves specific activities and statistical tools, such as control charts, Pareto charts, and process capability studies. These tools help teams identify root causes, implement solutions, and monitor progress.

Teams that use six sigma methodology benefit from data-driven decision making, which leads to fewer defects and more efficient processes.

Statistical analysis forms the foundation of six sigma. Teams use descriptive statistics, probability distributions, and hypothesis testing to understand and control process variation. This scientific approach ensures that process improvements are based on evidence, not guesswork.

Evolution to 2025

Six sigma began in manufacturing but has evolved into a global quality management strategy used across many industries. By 2025, six sigma methodology has become essential for organizations seeking operational excellence. Systems and teams now apply six sigma in healthcare, finance, technology, and government, achieving measurable improvements in efficiency, cost savings, and customer satisfaction.

The following table shows how six sigma has expanded and delivered results in different sectors:

Industry Sector | Numerical Trend / Outcome | Description / Impact |

|---|---|---|

Automotive | Streamlined processes using Lean principles in a major automotive supplier. | |

General Manufacturing | Up to 20% cost savings within first year | Cost reduction achieved through Lean Six Sigma implementation. |

Various Industries | 22% cost reduction and 28% productivity increase | Companies applying Six Sigma methods reported these average improvements. |

Healthcare | Reduced patient waiting times | Improved quality of healthcare services through Six Sigma application. |

Financial Services | Reduced process errors and operational costs | Banks improved customer service and lowered costs using Lean Six Sigma. |

Six sigma methodology now integrates digital transformation, artificial intelligence, and the Internet of Things. These technologies help systems and teams analyze data faster and optimize processes in real time. Lean six sigma combines waste reduction with defect reduction, making it even more effective. Sustainability has also become a focus, with organizations using six sigma to reduce waste and support eco-friendly practices.

Clients at systems and teams achieve these results by adopting six sigma methodology and leveraging new technologies. Those interested in learning more can reach out to discover how six sigma can drive process improvement and quality management in their organizations.

DMAIC Process

The DMAIC process stands as the backbone of Six Sigma and modern process improvement. Systems and teams use the DMAIC method to systematically improve processes, reduce variation, and deliver measurable results. DMAIC stands for Define, Measure, Analyze, Improve, and Control. Each phase uses specific tools and statistical methods to ensure success. While DMAIC focuses on improving existing processes, teams use Design for Six Sigma (DFSS) for new process designs.

Define

In the Define phase, systems and teams set the foundation for successful process improvement. They identify the problem, clarify project goals, and align everyone involved. Teams gather Voice of the Customer (VoC) feedback to pinpoint what matters most. They translate these needs into Critical-to-Quality (CTQ) elements, which become measurable standards. Teams then create a clear problem statement and set SMART goals—Specific, Measurable, Achievable, Relevant, and Time-bound.

A well-structured project charter outlines the project scope, objectives, and team roles. Stakeholder analysis ensures everyone understands their part. Teams use SIPOC (Suppliers, Inputs, Process, Outputs, Customers) maps to visualize the process boundaries. Digital project dashboards help track goals and timelines, keeping everyone on the same page.

Success Metric / Deliverable | Description |

|---|---|

Frequency of errors occurring in the process | |

Cycle Times | Duration taken to complete the process |

Cost Impact | Financial losses due to inefficiencies |

Customer Satisfaction Scores | Customer perception of quality and service |

Problem Statement | A precise, measurable statement defining the issue |

SMART Goals | Specific, Measurable, Achievable, Relevant, Time-bound objectives to guide the project |

Project Charter | Document outlining project scope, objectives, and team roles |

SIPOC Process Map | High-level mapping of Suppliers, Inputs, Process, Outputs, and Customers |

Baseline Metrics | Initial data points to establish current performance before improvements |

Teams that invest time in the Define phase create a strong, data-driven foundation for the rest of the DMAIC process.

Measure

The Measure phase focuses on collecting accurate data to understand the current state of the process. Systems and teams identify key performance indicators (KPIs) and use automated data capture tools to ensure reliability. Measurement System Analysis (MSA) tools, such as Gauge R&R studies, help assess the accuracy and consistency of the measurement system. Teams establish baseline metrics like defect rates, cycle times, and cost impact.

A recent report shows that 42% of organizations face challenges in collecting reliable data during this phase, highlighting its importance. However, organizations that complete the Measure phase successfully see an average 35% improvement in process performance. This phase ensures that teams have the right data to drive effective process improvement.

Tip: Reliable data collection in the Measure phase sets the stage for accurate analysis and successful outcomes.

Analyze

During the Analyze phase, systems and teams use data to uncover the root causes of problems. They apply root cause analysis techniques, such as the Five Whys and cause-and-effect diagrams, to break down issues to their source. Teams use advanced analytics software, including Minitab and JMP, to process data and identify trends, outliers, and patterns.

Graphical analysis tools—like histograms, Pareto charts, scatter plots, and box plots—help visualize data and prioritize issues. Failure Mode and Effects Analysis (FMEA) identifies potential failure points and their impact. Statistical Process Control (SPC) monitors process behavior and highlights areas needing improvement.

Common tools in the Analyze phase:

Cause-and-effect diagrams

Five Whys

Pareto charts

FMEA

Graphical analysis tools (histograms, scatter plots, box plots)

Statistical Process Control (SPC)

By using these tools, clients at systems and teams can identify the true sources of variation and focus their process improvement efforts where they matter most. Teams that want to learn more about how to analyze data effectively or apply root cause analysis can reach out for guidance.

Improve

The Improve phase in the dmaic process brings real change to organizations. Systems and teams use this phase to develop and test solutions that address the root causes found earlier. They focus on making changes that lead to better results in process improvement. The main goal is to improve processes by removing barriers and making work easier and faster.

Teams start by brainstorming ideas and selecting the best solutions. They use process mapping and root cause analysis to make sure their ideas target the right problems. Pilot testing helps teams see if their solutions work before making big changes. This step reduces risk and builds confidence in the new approach.

Tip: Pilot testing allows systems and teams to catch problems early and adjust solutions for the best results.

During the Improve phase, teams often use new technology, update training methods, or change how they communicate. These actions help everyone adapt to the new process. Change management plays a big role in making sure improvements last. Teams also prepare for hand-off to process owners, so the changes become part of daily work.

The dmaic process supports process improvement by focusing on key performance indicators (KPIs). Teams track these KPIs to measure success. Some common improvements seen in the Improve phase include:

Higher inventory turnover rates

More on-time deliveries

Fewer defects in products or services

Shorter lead times

Systems and teams see gains in customer satisfaction, productivity, and financial savings. They use tools like brainstorming, process mapping, and pilot programs to support these results. The dmaic process encourages innovation and adaptation, helping organizations stay competitive.

The Improve phase also prepares teams for the next step—Control. By embedding changes into daily operations, teams make sure improvements last. Regular monitoring and feedback keep the process on track.

Clients at systems and teams achieve these results by following the dmaic process and using proven tools. Those who want to learn more about how to improve processes or need help with process improvement can reach out for expert guidance.

Six Sigma vs. Lean and Lean Six Sigma

Differences

Six sigma and lean both aim for continuous improvement, but they use different methods. Six sigma focuses on reducing defects and controlling process variation through statistical analysis. It uses the DMAIC framework and sets a clear target of no more than 3.4 defects per million opportunities. Lean, on the other hand, works to eliminate waste and improve process flow. Lean does not set a specific numerical defect target and does not use a formal certification system. Six sigma uses a belt system to show proficiency, while lean does not.

Aspect | Six Sigma | Lean |

|---|---|---|

Defect Rate Target | Aims for no more than 3.4 defects per million opportunities | No specific numerical defect rate target |

Methodology | Uses DMAIC for reducing variability and defects | Focuses on eliminating waste and non-value-adding processes |

Proficiency Levels | Belt system (White, Yellow, Green, Black, Master Black Belt) | No belt system or formal proficiency levels |

Focus | Statistical control, reduction of process variability, data-driven | Waste elimination, process flow improvement |

Continuous Improvement | Emphasizes statistical rigor and data analysis | Emphasizes process efficiency and waste removal |

Six sigma brings structure and data analysis to process improvement, while lean brings speed and waste reduction.

Integration

Many organizations now combine six sigma and lean into lean six sigma. This integration allows systems and teams to use the strengths of both methods. Lean six sigma uses the DMAIC framework from six sigma and the waste reduction tools from lean. In 2025, case studies from the automotive industry in Sao Paulo show that lean six sigma improves productivity and quality. Employees learn more about statistics and problem-solving, which helps systems and teams stay competitive.

Amazon uses lean six sigma to optimize warehouse operations for fast shipping. Leadership supports cultural change, making lean six sigma part of daily work. Other companies like Toyota, General Electric, and Dell also use lean six sigma to reduce waste, improve quality, and streamline supply chains. Clients at systems and teams see these results by adopting lean six sigma and involving everyone in the process.

Toyota reduced waste and improved efficiency with lean six sigma.

General Electric achieved cost reductions and better quality using six sigma.

Dell improved inventory and delivery with lean methods.

Lean six sigma helps systems and teams reach higher performance by combining data-driven decisions with efficient processes.

When to Use Each

Choosing between six sigma, lean, or lean six sigma depends on the problem and the goals. Six sigma works best when a process has too many defects or high variation. Lean is a good choice when the main issue is waste or slow process flow. Lean six sigma fits when both defects and waste need attention.

Performance metrics help systems and teams decide which method to use. Metrics like sigma level, defects per million opportunities (DPMO), and cost of poor quality (COPQ) show when six sigma is needed. First time yield (FTY) and rolled throughput yield (RTY) help identify lean or lean six sigma projects. Process capability indices (Cp, Cpk) measure how well a process meets requirements.

Performance Metric | Description | Importance in Methodology Application |

|---|---|---|

Sigma Level | Measures process variation and ability to meet customer needs. | Guides use of six sigma or lean six sigma. |

Defects Per Million Opportunities (DPMO) | Counts defects per million chances for error. | Shows when six sigma is needed to reduce defects. |

Cost of Poor Quality (COPQ) | Calculates financial losses from defects. | Helps decide between lean or six sigma. |

First Time Yield (FTY) | Percentage of units done right the first time. | Points to lean or six sigma projects. |

Rolled Throughput Yield (RTY) | Measures quality across all steps. | Useful for lean six sigma to improve end-to-end processes. |

Process Capability Indices (Cp, Cpk) | Shows how well a process meets limits. | Essential for six sigma or lean six sigma interventions. |

Systems and teams that track these metrics can choose the right method for their needs. Clients at systems and teams achieve better results by matching the right approach to the right problem. Those who want to learn more about selecting the best method for their process can reach out for expert guidance.

Six Sigma Certification

Certification Levels

Six sigma certification offers a structured path for professionals who want to improve their process improvement skills. The certification system uses a belt structure, similar to martial arts, to show expertise and responsibility. Each level builds on the previous one, allowing individuals to grow their knowledge and impact within systems and teams.

Certification Level | Description of Expertise and Role | Career Benefits and Impact |

|---|---|---|

White Belt | Basic understanding of Six Sigma principles; supporting team member role | Entry-level awareness; contributes at a basic level |

Yellow Belt | Fundamental knowledge of Six Sigma tools; supports Green and Black Belts | Participates in projects; foundational career step |

Green Belt | Advanced proficiency; leads small projects; assists Black Belts | Leads departmental projects; gains leadership experience |

Black Belt | Mastery of Six Sigma; leads complex projects; mentors Green Belts | Manages major initiatives; coaching role; higher responsibility |

Master Black Belt | Exceptional expertise; strategic leadership; mentors all belts | Drives enterprise-wide improvements; aligns Six Sigma with business goals; top leadership role |

Professionals who earn six sigma certification often see higher salaries and more job opportunities. For example, certified Green Belts in the U.S. earn an average annual salary of $118,000, while those with a six sigma black belt earn about $135,400. These roles allow individuals to lead projects, mentor others, and move into leadership positions. Clients at systems and teams benefit from having certified staff who can drive process improvement and deliver measurable results.

2025 Updates

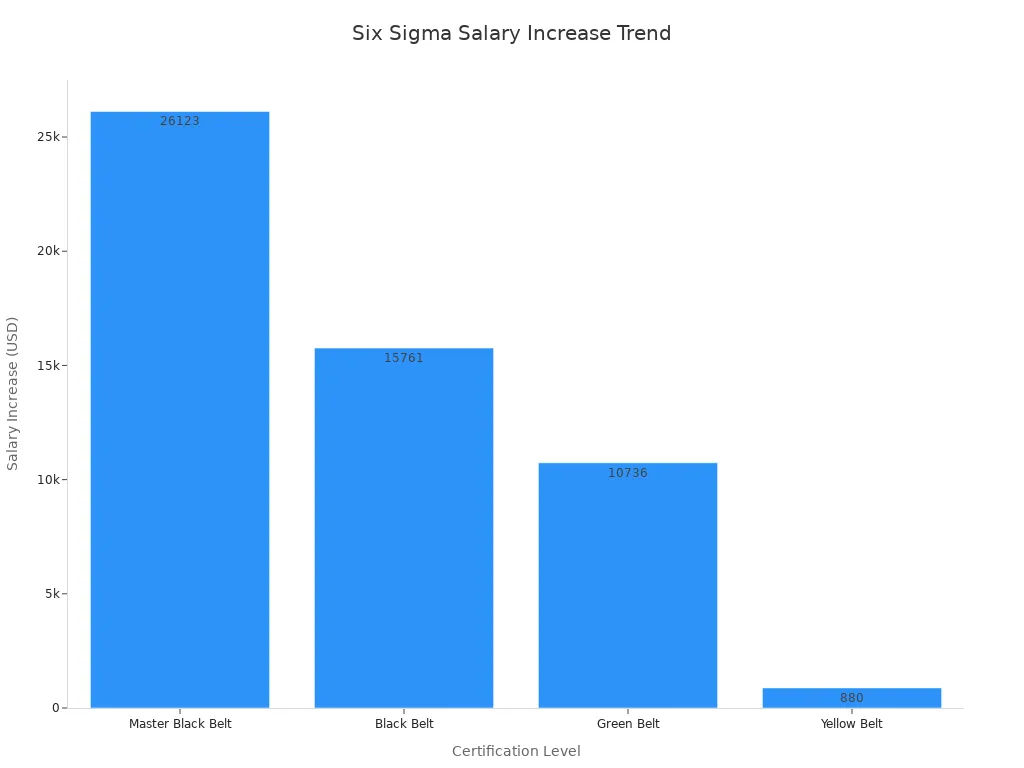

In 2025, the demand for six sigma certification continues to rise. Organizations across industries such as manufacturing, healthcare, IT, and finance seek certified professionals to lead quality improvement efforts. The ASQ Quality Progress Salary Survey shows a clear trend: higher certification levels bring greater financial rewards.

Certification Level | Average Annual Salary Increase (USD) |

|---|---|

Master Black Belt | $26,123 |

Black Belt | $15,761 |

Green Belt | $10,736 |

Yellow Belt | $880 |

Six sigma-certified professionals can earn up to 40% more than non-certified peers. Many move into leadership roles and help systems and teams achieve higher efficiency. Six sigma certification also supports career growth by opening doors to new industries and responsibilities. Companies like General Electric have saved billions through six sigma initiatives, showing the real-world value of certification.

Note: Clients at systems and teams who invest in six sigma certification see measurable gains in quality, cost savings, and customer satisfaction. Those interested in learning more can reach out for guidance on certification paths.

Online Options

Online learning has made six sigma certification more accessible in 2025. Many accredited organizations offer flexible online courses for every belt level, including six sigma black belt and six sigma master black belt programs. These courses use interactive modules, live webinars, and virtual simulations to help learners build practical skills.

Self-paced courses allow professionals to study while working full-time.

Online exams and digital badges make it easy to showcase achievements.

Systems and teams can enroll groups of employees to build a culture of continuous improvement.

Six sigma certification online helps clients at systems and teams upskill their workforce quickly and efficiently. Many platforms provide mentorship, project support, and exam preparation resources. This approach ensures that learners gain both theoretical knowledge and hands-on experience.

Tip: Choosing an accredited provider ensures that six sigma certification meets industry standards and delivers recognized value.

Process Improvement Benefits

Applications Across Industries

Six Sigma drives operational excellence in many industries. Systems and teams in manufacturing, healthcare, finance, and construction use process improvement to achieve measurable gains. For example, Motorola reached 6 Sigma quality, producing high-quality products with almost no defects. Johnson & Johnson saved $600 million after applying continuous improvement strategies. In construction, Bechtel invested $30 million in Six Sigma and saved over $200 million by reducing rework and defects. Financial companies like American Express improved accuracy and reduced errors, reaching Sigma Levels of 4 to 5.

The following table shows how different Sigma Levels relate to defect rates and industry examples:

Sigma Level | Defect Rate (DPMO) | Yield Percentage | Industry Examples and Impact |

|---|---|---|---|

3 Sigma | ~66,807 | 93.32% | Baseline for many processes |

4 Sigma | ~6,210 | 99.38% | Consumer electronics, improved accuracy |

5 Sigma | ~233 | 99.98% | Automotive, high reliability |

6 Sigma | ~3.4 | 99.9997% | Motorola, Mayo Clinic, top quality control |

Clients at systems and teams see these results by focusing on continuous process improvement and using data-driven methods. They often report higher productivity, faster production cycles, and fewer emergency fixes. Companies like Microsoft, Boeing, and Linde Group have all used Six Sigma to streamline operations and boost productivity.

Customer Focus

Operational excellence depends on meeting customer needs. Six Sigma places the customer at the center of every process improvement effort. Systems and teams use Voice of Customer research to understand what matters most. They then align processes to deliver consistent quality and fast service.

Six Sigma initiatives help reduce defects and errors, leading to fewer complaints and returns. This approach builds trust and loyalty.

Metrics such as Customer Satisfaction Scores (CSAT) and Net Promoter Scores (NPS) show improvements after continuous improvement projects. Teams track defect rates and turnaround times to ensure they meet customer expectations. Improved feedback loops allow systems and teams to act quickly on customer input, driving further continuous improvement.

Enhanced product and service quality

Faster problem resolution

Consistent delivery and reduced variability

Competitive advantage through reliable service

Clients at systems and teams who focus on customer needs achieve higher satisfaction and stronger brand loyalty. Those interested in learning more about customer-focused quality management can reach out for guidance.

Efficiency and Profitability

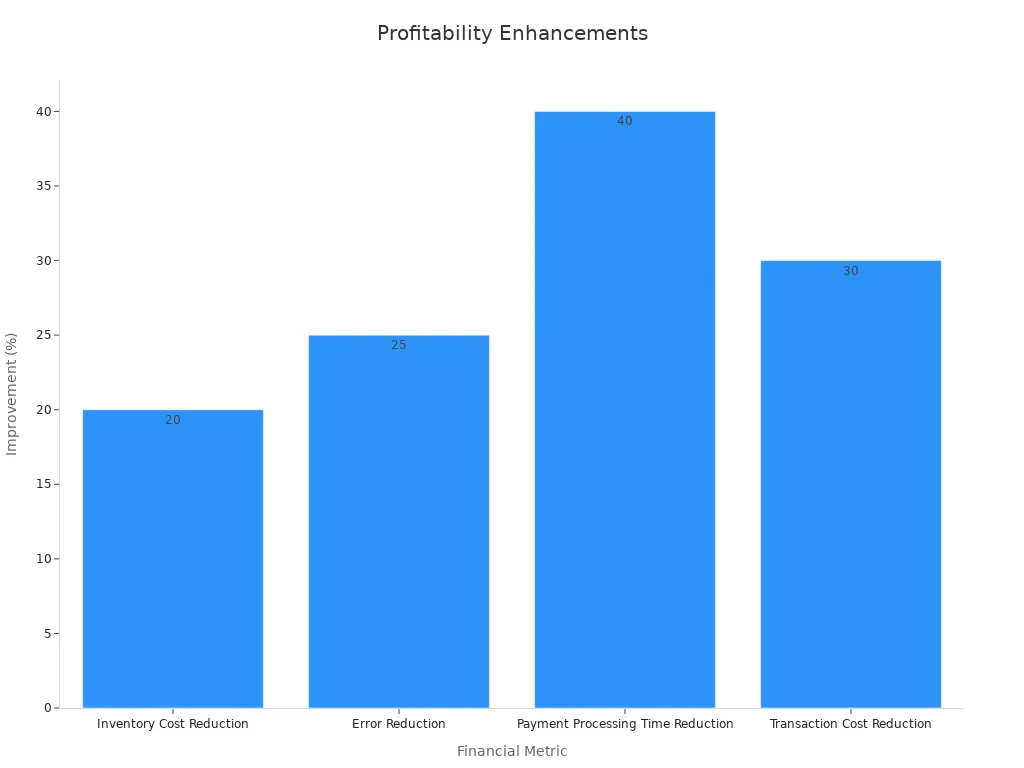

Six Sigma delivers strong financial results through process improvement and operational excellence. Systems and teams see lower costs, faster workflows, and better resource use. The DMAIC methodology helps track financial returns and cost savings.

Financial Metric | Improvement Achieved |

|---|---|

Inventory Cost Reduction | 20% |

Error Reduction | 25% |

Payment Processing Time Reduction | 40% |

Transaction Cost Reduction | 30% |

Continuous improvement leads to leaner operating costs and better financial visibility. Systems and teams benefit from fewer defects, less waste, and more predictable operations. Clients at systems and teams who invest in operational excellence gain a competitive edge and long-term business stability. Those seeking to improve efficiency and profitability can reach out for expert support.

Getting Started with Six Sigma

First Steps

Many organizations want to launch Six Sigma but wonder where to begin. Systems and teams can follow a clear path to start their journey. The first steps help build a strong foundation for process improvement and measurable results.

Define: Identify the process and problem that need attention. Clear goals help everyone focus on what matters most.

Measure: Collect data to set a performance benchmark. Reliable data shows where the process stands today.

Analyze: Use statistical analysis to find the root causes of defects. Teams look for patterns and sources of variation.

Improve: Make changes based on data-driven insights. Pilot new solutions and monitor their impact.

Control: Maintain improvements with ongoing measurement and controls. Regular checks keep the process on track.

Leaders play a key role by supporting these steps. They create urgency by showing the business impact of problems, such as lost revenue or market share. Systems and teams need the right people and skills to succeed. Assigning ownership and responsibility increases accountability. The phrase "when something cannot be measured, it cannot be improved" highlights why measurement is so important in Six Sigma.

Training Resources

Training gives systems and teams the knowledge they need to succeed with Six Sigma. Many organizations offer online and in-person courses for every skill level. These programs teach the basics of Six Sigma, including statistical tools and the DMAIC process. Black Belt and Green Belt training help team members lead projects and analyze data.

Self-paced courses allow learners to study at their own speed.

Live webinars and workshops provide hands-on practice.

Certification programs help systems and teams build a culture of continuous improvement.

Clients at systems and teams often use these resources to upskill their workforce. Many training providers offer mentorship and project support. This guidance helps teams apply what they learn to real-world problems. Those who want to learn more about training options can reach out for recommendations.

Tips for Success

Systems and teams that follow proven tips see better results from Six Sigma. They focus on clear goals, reliable data, and teamwork. The table below shows how key performance indicators improve when teams use these tips:

Key Performance Indicator | Description | Improvement Result from Following Six Sigma Tips |

|---|---|---|

Cycle Time | Time taken to complete a process or task from start to finish. | Reduced cycle time leads to higher throughput, faster delivery, and improved customer satisfaction. |

Defect Rate | Number of defects or errors occurring in a process. | Lower defect rates indicate improved process quality and fewer errors. |

First-Pass Yield | Percentage of units or tasks completed without rework. | Higher first-pass yield reflects increased process efficiency and reduced waste. |

Customer Satisfaction | Measurement of how well processes meet customer expectations via surveys or feedback. | Increased customer satisfaction demonstrates better alignment with customer needs and loyalty. |

Tip: Systems and teams should celebrate small wins and share progress. This builds momentum and keeps everyone motivated.

Clients at systems and teams who use these tips often see faster results and stronger engagement. They create a culture where everyone looks for ways to improve. Those interested in learning more about successful Six Sigma practices can reach out for expert advice.

Six sigma continues to deliver measurable value and adaptability for systems and teams in 2025. The DMAIC framework and lean six sigma culture help reduce defects, improve process quality, and increase customer satisfaction. Clients at systems and teams achieve long-term improvements, such as defect rate reductions and cost savings, by applying six sigma. Those who pursue six sigma certification gain practical skills, leadership opportunities, and career growth. Next steps include exploring training or joining six sigma communities. Every experience level can benefit from a commitment to continuous improvement.

FAQ

What is the main goal of Six Sigma in 2025?

Six Sigma aims to help systems and teams reduce defects and improve process quality. Clients at systems and teams use data-driven methods to achieve better results and higher customer satisfaction. Those who want more details can reach out for guidance.

How do systems and teams start a Six Sigma project?

They begin by defining the problem, collecting data, and analyzing root causes. Clients at systems and teams often use the DMAIC process to guide each step. Reaching out for expert support can help ensure success.

Can Six Sigma work outside manufacturing?

Yes. Systems and teams in healthcare, finance, and technology use Six Sigma to improve service quality and reduce errors. Clients at systems and teams see benefits across many industries. For more examples, readers can contact us.

What tools do teams use in Six Sigma?

Teams use control charts, Pareto charts, and process maps. These tools help systems and teams find problems and measure improvements. Clients at systems and teams often see faster results by using these tools.

How long does it take to see results from Six Sigma?

Most systems and teams notice improvements within a few months. The timeline depends on project size and team effort. Clients at systems and teams who follow best practices often see faster gains. For tips, readers can reach out.

Is Six Sigma certification necessary for success?

Certification helps systems and teams build skills and lead projects. Clients at systems and teams with certified members often achieve better outcomes. Those interested in certification can contact us for training options.

How does Six Sigma improve customer satisfaction?

Six Sigma helps systems and teams deliver consistent quality and fewer errors. Clients at systems and teams report higher customer satisfaction after using Six Sigma. To learn more about customer-focused improvements, readers can reach out.