Understanding Business Process Improvement Methodologies for Lasting Success

Imagine a company struggling with slow hiring systems or wasted resources. Business process improvement methodologies offer structured ways to make these challenges easier to manage. These methods use optimization steps to improve efficiency and quality. Many organizations turn to digital tools to automate routine tasks, optimize workflows, and gain real-time insights.

Digital integration helps reduce waste, improve inventory, and support smarter decision-making.

Companies use these approaches to balance economic, social, and environmental goals while making each process more effective.

Key Takeaways

Business process improvement methods help companies work faster, reduce waste, and improve quality.

Popular methodologies include Lean, Six Sigma, Kaizen, Agile, and Total Quality Management, each with unique strengths.

Choosing the right method depends on a company’s goals, culture, and the problems it faces.

Successful improvement requires clear planning, teamwork, training, and ongoing measurement of results.

Involving employees and stakeholders early reduces resistance and builds support for changes.

Using technology like automation and data analytics speeds up improvements and keeps progress on track.

Overcoming challenges like resistance and limited resources needs clear communication and focus on high-impact projects.

Continuous improvement and recognizing employee efforts help maintain gains and build a culture of success.

What Are Business Process Improvement Methodologies?

Definition

Business process improvement methodologies are structured approaches that help organizations identify, analyze, and optimize their workflows. These methods focus on increasing efficiency, reducing waste, and improving quality. Companies use them to examine current processes, find bottlenecks, and redesign steps for better results. The most recognized methodologies include Six Sigma, Lean Manufacturing, Total Quality Management (TQM), Kaizen, and Agile. Each method uses specific tools and steps to guide teams through improvement cycles.

Tip: Systematic analysis and data-driven measurement form the foundation of these methodologies. Teams often use metrics like resource utilization, cycle times, and error rates to spot inefficiencies.

Methodology | Core Principles / Description | Key Tools / Features |

|---|---|---|

Six Sigma | Reduces defects and variability using data-driven approaches. | DMAIC steps, statistical analysis, SIPOC diagrams |

Lean Manufacturing | Eliminates waste and improves value by removing non-value-added activities. | Value stream mapping, waste identification |

Total Quality Management | Focuses on customer satisfaction, employee involvement, and continuous improvement. | PDCA cycles, flowcharts, check sheets |

Kaizen | Promotes continuous incremental improvements involving all employees. | Employee suggestion systems, regular audits |

Agile | Encourages flexibility and rapid adaptation to change. | Iterative cycles, cross-functional teams |

Why They Matter

Business process improvement methodologies matter because they help organizations stay competitive and responsive. By using these methods, companies can adapt to market changes, meet customer expectations, and comply with regulations. Data-driven decision making ensures that changes are based on facts, not guesses. Involving employees in the process increases buy-in and sparks innovation. Many organizations report productivity improvements of 30% to 50% after adopting these approaches. They also see higher returns on investment and faster response times.

Systematic analysis uncovers hidden inefficiencies.

Redesigning processes often leads to automation and better resource use.

Regular monitoring ensures that improvements last over time.

Key Benefits

Organizations that use business process improvement methodologies experience several measurable benefits:

Increased productivity through faster task completion and focus on high-value activities.

Reduced inefficiencies by eliminating redundant tasks and waste.

Improved quality by minimizing errors and ensuring consistent standards.

Lower operational costs from optimized resource use.

Enhanced customer satisfaction due to reliable quality and timely delivery.

Greater adaptability to regulatory changes and market demands.

Competitive advantage through ongoing process improvements.

For example, a car manufacturing plant used the Kaizen method to reorganize its workspace. This change reduced unnecessary movement, shortened assembly times, and boosted overall productivity. Companies also report higher employee engagement and better teamwork when everyone participates in improvement efforts.

Main Methodologies

Lean

Principles

Lean focuses on maximizing value for customers while minimizing waste. Organizations use Lean to streamline processes, improve efficiency, and foster a culture of continuous improvement. The core principles of Lean include:

Managing workflow to reduce bottlenecks and forecast capacity.

Saving costs by avoiding overproduction and excess inventory.

Adapting quickly to market changes and customer needs.

Building strong customer relationships by centering on customer value.

Encouraging ongoing refinement and innovation.

Core Principle | Description | Real-World Validation Example |

|---|---|---|

Define Value | Focus on what the customer is willing to pay for; value must be defined from the customer's perspective. | Toyota and healthcare examples emphasize defining value as customer-centric, e.g., shorter wait times in healthcare. |

Map the Value Stream | Visualize all steps from concept to delivery to identify and eliminate waste. | Virginia Mason Medical Center mapped patient pathways to reduce redundant steps and improve flow. |

Create Flow | Ensure continuous, uninterrupted movement of products or services without delays or bottlenecks. | Toyota restructured assembly lines to create smooth flow, reducing waste and improving quality. |

Establish Pull | Production is triggered by actual demand, reducing inventory and overproduction. | Toyota's Kanban system manages parts inventory based on demand, avoiding excess stock. |

Pursue Perfection | Continuous improvement through incremental changes aiming for zero waste and defects. | Toyota's Kaizen culture drives daily improvements; Virginia Mason uses 5S and continuous improvement tools. |

Applications

Lean has transformed many industries. Manufacturing sectors such as automotive, aerospace, and electronics have used Lean to boost efficiency and cut costs. Service industries, including healthcare, banking, and hospitality, have also adopted Lean to improve customer service and streamline operations. For example:

Hospitals use Lean to reduce patient wait times and improve care quality.

Banks and insurance companies streamline processes to enhance customer experience.

Government agencies apply Lean to allocate resources efficiently and save millions.

Hotels coordinate complex operations and empower staff using Lean principles.

Food and beverage companies maintain quality and cut waste, supporting profitability and sustainability.

Lean helps organizations in both public and private sectors achieve better results by focusing on value and eliminating unnecessary steps.

Six Sigma

Principles

Six Sigma aims to reduce defects and improve quality by using data-driven methods. The approach relies on statistical analysis to identify and remove causes of errors. Six Sigma sets a high standard for process quality, targeting only 3.4 defects per million opportunities. This goal pushes organizations to achieve near-perfect results.

Six Sigma uses the DMAIC framework (Define, Measure, Analyze, Improve, Control) to guide improvement projects. The methodology measures process capability with sigma levels, using tools like control charts and hypothesis testing. By focusing on reducing variation, Six Sigma helps companies deliver consistent products and services.

Motorola, the pioneer of Six Sigma, reported over $17 billion in savings from its initiatives. General Electric also achieved more than $1 billion in cost savings, showing the financial impact of Six Sigma. By the late 1990s, about two-thirds of Fortune 500 companies had adopted Six Sigma to cut costs and improve quality.

Applications

Six Sigma works in both manufacturing and service industries. In manufacturing, companies use Six Sigma to balance assembly lines, reduce setup times, and control quality. For example, a medical device manufacturer increased throughput by 35% without extra equipment or staff. An automotive parts supplier reduced setup time from 45 to 8 minutes, gaining over 100 hours per year.

In service industries, Six Sigma adapts to fit transactional processes. Banks and insurance companies use it to improve compliance and customer satisfaction. IT companies apply Six Sigma to reduce defects in software development and optimize infrastructure. Public agencies and the military use Six Sigma to improve efficiency and cut costs.

Common applications include:

Eliminating variation in product lifecycles for consistent outcomes.

Achieving near-zero defects to ensure product superiority.

Using DMAIC and hypothesis testing to optimize costs and returns.

Improving customer satisfaction through Voice of Customer research.

Increasing business stability by reducing variability and improving process control.

Application Area | Description | Example Outcome |

|---|---|---|

Process Improvement | Assembly line balancing to identify bottlenecks and redistribute work for smoother flow. | Medical device manufacturer increased throughput by 35% without extra equipment or staff. |

Setup Time Reduction | Using SMED techniques combined with Six Sigma statistical analysis to cut changeover times. | Automotive parts supplier reduced setup time from 45 to 8 minutes, gaining 100+ hours/year. |

Quality Control | Statistical Process Control (SPC) to monitor processes and root cause analysis tools (5 Whys, Fishbone diagrams). | Semiconductor manufacturer cut defect rates by 72%, saving millions; furniture maker reduced complaints by 83%. |

Waste Reduction | Addressing the 8 wastes (defects, overproduction, waiting, etc.) and inventory optimization using pull systems and kanban. | Food plant cut transportation waste by 60%, improved throughput by 15%; electronics firm reduced WIP inventory by 52%. |

Total Quality Management

Principles

Total Quality Management (TQM) is a company-wide approach that focuses on long-term success through customer satisfaction. TQM involves every employee, from entry-level to executives, in improving processes and delivering quality. The main principles of TQM include:

Understanding customer requirements to ensure satisfaction and retention.

Leadership commitment to communicate vision and support continuous improvement.

Integration of all organizational functions, such as strategy, production, marketing, and finance.

Employee involvement in quality initiatives, fostering teamwork and motivation.

Use of systematic tools like the PDCA (Plan-Do-Check-Act) cycle for continuous improvement.

Emphasis on process priority, business process integration, and a strategic approach.

Constant improvement to adapt and sustain growth in changing markets.

TQM’s eight principles—customer focus, total involvement, process priority, business process integration, strategic systematic approach, and constant improvement—drive operational excellence and long-term business success.

Applications

TQM applies to many industries, including manufacturing, banking, hospitality, education, and pharmaceuticals. Organizations use TQM to improve product and service quality, reduce defects, and meet customer expectations. For example, Toyota’s success with TQM shows how quality control and continuous improvement lead to lasting business results.

Key applications of TQM include:

Enhancing customer satisfaction and loyalty by prioritizing customer needs.

Improving operational efficiency through process optimization and waste reduction.

Increasing employee engagement by empowering staff to participate in quality initiatives.

Reducing errors and defects with rigorous process control and continuous improvement.

Supporting sustainability and long-term growth by adapting to market changes.

TQM uses tools such as the PDCA cycle, Kaizen, and Six Sigma to drive improvements. Implementation involves leadership commitment, employee training, process mapping, and ongoing evaluation. These steps help organizations build a culture of quality and achieve sustainable excellence.

Kaizen

Principles

Kaizen means "continuous improvement" in Japanese. This methodology encourages everyone in an organization to look for small, daily changes that can improve processes. Kaizen focuses on teamwork, personal discipline, and a willingness to challenge the status quo. Leaders support employees at all levels to suggest improvements. The approach values incremental progress over time rather than large, sudden changes.

Key principles of Kaizen include:

Continuous, incremental improvement

Employee involvement at every level

Standardization of best practices

Focus on eliminating waste

Emphasis on quality, efficiency, and safety

Kaizen creates a culture where people feel responsible for making their work better. Teams regularly review processes, identify problems, and test solutions. This mindset leads to steady progress and long-term success.

Applications

Organizations use Kaizen in many industries, from manufacturing to healthcare and retail. Companies like Toyota, Virginia Mason Medical Center, and Tesco have seen strong results by applying Kaizen principles.

Main outcomes reported by companies implementing Kaizen:

Improved production quality through continuous defect reduction and quality control

Increased productivity by eliminating waste and streamlining operations

Reduced costs by optimizing resource use and cutting unnecessary expenses

Enhanced employee involvement and motivation by encouraging contributions from all levels

Better health and safety measures by identifying and correcting unsafe conditions

Greater adaptability and responsiveness to market changes, maintaining competitiveness

Sustained efficiency and operational improvements through standardization and incremental changes

Higher quality control leading to improved customer satisfaction and loyalty

A culture of continuous learning and proactive problem-solving fostering innovation

For example, Toyota used Kaizen to reduce waste, improve quality, and speed up production. Virginia Mason Medical Center applied Kaizen to cut patient wait times and minimize errors. Tesco streamlined its supply chain, reduced costs, and improved customer service. These examples show how Kaizen helps organizations achieve lasting improvements and stay competitive.

PDCA

Principles

The PDCA cycle stands for Plan-Do-Check-Act. This method provides a simple, logical way to improve processes. Teams start by planning a change, then carry it out, check the results, and act based on what they learn. The cycle repeats, allowing for ongoing improvement.

PDCA relies on the scientific method. Teams use data to test ideas and measure results. This approach helps organizations find the root causes of problems and make informed decisions. PDCA encourages small, controlled changes rather than risky, large-scale shifts.

Key principles of PDCA include:

Planning improvements based on data and analysis

Testing changes on a small scale

Checking results with clear metrics

Acting to standardize successful changes or adjust as needed

Repeating the cycle for continuous improvement

Applications

PDCA works in many settings, including manufacturing, healthcare, project management, and product development. It forms the foundation of Total Quality Management and supports Six Sigma projects.

The PDCA cycle helps teams reduce waste, increase productivity, and build a culture of continuous improvement. It also lowers risks by allowing organizations to test changes before full implementation. For example, healthcare providers use PDCA to improve patient care and eliminate waste. Manufacturing companies apply PDCA to reduce defects and improve efficiency.

PDCA in action:

Supports data collection and statistical analysis for root cause identification

Improves project performance, strategy planning, and fault detection

Applicable in product development, project management, and supply chain

Healthcare industry uses PDCA for continuous improvement and waste elimination

Case studies show PDCA reduces defects and improves management efficiency in assembly workstations

Application with 5S reduced sewing errors and increased profits in textile companies

Integration with quality tools like Ishikawa diagrams improved packaging design

Proper use of PDCA requires careful documentation and attention to each step. Skipping steps or improper use can lead to poor results. When applied correctly, PDCA provides a reliable path to ongoing process improvement.

Agile

Principles

Agile is a methodology that values flexibility, collaboration, and rapid response to change. Teams work in short cycles, called sprints, to deliver small pieces of a project. Agile encourages regular feedback from customers and stakeholders. This approach helps teams adapt quickly and deliver value faster.

Core principles of Agile include:

Delivering work in small, manageable increments

Emphasizing collaboration among cross-functional teams

Welcoming changing requirements, even late in a project

Focusing on customer satisfaction through early and continuous delivery

Encouraging self-organizing teams and regular reflection for improvement

Agile promotes transparency and open communication. Teams hold daily meetings to discuss progress and challenges. This structure helps everyone stay aligned and focused on shared goals.

Applications

Technology companies often use Agile to speed up software development and respond to customer needs. Agile also works in marketing, product design, and other fields that require quick adaptation.

Agile methods, such as Scrum, have helped companies deliver products up to 40% faster and cut development costs by 35% compared to traditional methods. Teams deliver updates every 2-4 weeks, involve customers throughout the process, and adapt quickly to feedback. This leads to faster delivery cycles, improved adaptability, and higher team productivity.

Company | Reason for Adoption | Outcome Highlights | |

|---|---|---|---|

altLINE Sobanco | Scrum | To better manage client needs | Enhanced flexibility and adaptability; optimized cash flow |

InspectNTrack | Scrum | To shift from linear to adaptable process | Faster development cycles; improved client satisfaction |

Lake.com | Scrum | To implement new solutions safely and efficiently | Increased flexibility; better services; higher customer satisfaction |

TrainerFu | Scrum | To boost collaboration and adaptability | Improved collaboration; faster product delivery |

Ling | Scrum | To drive adaptability and continuous improvement | Accelerated growth; rapid pivoting; launched new features in under six weeks |

Penta Technologies | Scrum | To reduce silos and speed delivery | Delivery times reduced; employee satisfaction rose from 38% to 98% |

Sipgate | Scrum, Lean | To increase cohesion and accelerate product development | Improved transparency; faster product development |

VistaPrint reduced software release cycles from 18 months to three weeks after adopting Agile. FitBit used Agile to meet tight production schedules and launch new products ahead of deadlines. These examples show how Agile helps organizations deliver results quickly, adapt to change, and improve customer satisfaction.

Kanban

Principles

Kanban is a visual workflow management method that helps teams organize tasks and improve productivity. The system uses boards with columns to represent different stages of work. Each task moves from one column to the next as progress occurs. Kanban limits the number of tasks in progress at any time, which prevents overload and exposes bottlenecks.

Key principles of Kanban include:

Visualizing work to increase transparency and communication.

Limiting work-in-progress (WIP) to maintain focus and prevent burnout.

Managing flow to ensure steady and predictable delivery.

Making process policies explicit so everyone understands how work moves.

Using feedback loops for continuous improvement.

Improving collaboratively by encouraging team input and adaptation.

Teams use Kanban to clarify responsibilities and make work visible. This approach supports accountability and helps workers complete tasks efficiently.

Applications

Organizations in software development, manufacturing, healthcare, and service industries use Kanban to streamline workflows. Kanban boards help teams track progress, identify delays, and adjust priorities quickly.

Kanban delivers several documented benefits in workflow management and productivity:

Visualizes work clearly, enhancing transparency and communication.

Limits WIP, preventing overload and improving focus.

Reduces overhead by minimizing status meetings and micromanagement.

Promotes continuous flow, enabling steady and predictable delivery.

Offers flexibility, allowing teams to tailor workflows.

Reduces waste by streamlining processes and minimizing multitasking.

Enhances collaboration and accountability through clear task ownership.

Improves customer satisfaction with faster delivery and higher quality.

Is simple to implement and adapt for teams of all sizes.

Kanban improves collaboration by making workflows transparent, which increases worker engagement and fosters teamwork. It reduces stress and workload by limiting WIP, preventing overload and burnout. Kanban supports continuous improvement, leading to ongoing organizational growth and higher quality outputs. Teams experience increased focus, faster decision-making, and more predictable delivery schedules. Many organizations report higher productivity and customer satisfaction after adopting Kanban.

Just-In-Time

Principles

Just-In-Time (JIT) is an inventory management strategy that aims to reduce waste and improve efficiency. Companies using JIT receive goods only when needed for production or sales, minimizing excess inventory and storage costs. JIT focuses on producing the right amount at the right time, which helps organizations respond quickly to customer demand.

Core principles of JIT include:

Eliminating excess inventory to lower costs and free up capital.

Synchronizing production with actual demand.

Reducing waste by preventing overordering and obsolete stock.

Improving quality through ongoing process refinement.

Building strong supplier partnerships for reliable delivery.

Engaging employees in continuous improvement efforts.

JIT encourages a culture of efficiency and adaptability. Teams monitor inventory levels closely and adjust orders based on real-time needs.

Applications

Manufacturers, retailers, and service providers use JIT to optimize supply chains and reduce operational costs. Automotive companies, electronics firms, and food services have achieved significant results with JIT.

Organizations have achieved notable outcomes by implementing JIT inventory management:

A mid-size food services company improved inventory accuracy, reduced waste, and enhanced customer satisfaction after adopting JIT. Operational costs related to overstocking and spoilage dropped significantly.

Dell minimized excess inventory, lowering storage and handling expenses. The company realized improved cash flow and reinvested capital in strategic areas. Dell offered high customization and responsiveness, setting an industry benchmark for supply chain efficiency.

JIT lowers inventory carrying costs and increases return on investment.

Waste reduction occurs by preventing overordering and reducing obsolete inventory.

Efficiency improves through elimination of unnecessary raw materials and storage costs.

Higher inventory turnover ratios and minimized inventory obsolescence result.

Productivity rises with faster product turnaround and shorter production runs.

Smoother production flow reduces bottlenecks and delays.

Lower costs result from receiving goods on an as-needed basis.

JIT fosters continuous improvement and operational efficiency. Employees engage in reducing waste and improving workflows. Companies experience better supplier relationships, higher productivity, and greater customer satisfaction.

Business Process Reengineering

Principles

Business Process Reengineering (BPR) is a radical approach to redesigning core business processes for dramatic improvements in performance. BPR challenges existing workflows and seeks to eliminate unnecessary steps. The goal is to achieve significant gains in cost, quality, speed, and customer satisfaction.

Key principles of BPR include:

Rethinking and redesigning processes from the ground up.

Focusing on outcomes that deliver value to customers.

Leveraging technology to automate and streamline operations.

Encouraging cross-functional collaboration for holistic solutions.

Measuring performance to track improvements and guide decisions.

Committing to bold changes rather than incremental adjustments.

BPR requires strong leadership and a willingness to challenge the status quo. Teams analyze processes, identify inefficiencies, and implement new solutions.

Applications

Large organizations in manufacturing, technology, and services have used BPR to transform operations. IBM and Ford Motor Company provide well-known examples of BPR success.

IBM streamlined ordering and delivery processes by implementing advanced technologies. The company reduced procurement lead time from 40 days to 4 days, saving $1 billion annually. Ford Motor Company reengineered production, logistics, and supply chain management, achieving a 75% reduction in order-to-delivery time and significant cost savings. Ford optimized production layouts, assembly lines, and inventory management, which led to lower production costs and better supplier coordination.

The success of BPR initiatives is measured through cost reduction, cycle time improvements, customer satisfaction, and productivity gains. IBM's efforts led to a $1 billion annual cost saving and drastically reduced lead times. Ford achieved a 75% reduction in order-to-delivery time. These examples show how BPR can radically improve efficiency, reduce costs, and increase customer satisfaction. BPR illustrates transformative power in large organizations and sets benchmarks for operational excellence.

Business Process Management

Principles

Business Process Management (BPM) offers a structured way to improve how organizations run their daily operations. BPM focuses on designing, modeling, executing, monitoring, and optimizing business processes. This approach helps companies manage workflows from start to finish, making sure each step adds value and supports business goals.

BPM stands out because it uses a full lifecycle approach. Teams start by identifying which processes need improvement. They gather detailed information, map out each step, and look for problems or delays. After analyzing the root causes, they redesign the process to remove inefficiencies. Stakeholders review the new process before it goes live. Once implemented, teams measure performance using key performance indicators (KPIs) and continue to monitor results for ongoing improvement.

Note: BPM encourages continuous monitoring and real-time adjustments. This helps organizations stay flexible and respond quickly to changes in the market or customer needs.

A typical BPM lifecycle includes:

Identifying processes that need improvement using performance metrics.

Gathering detailed information about current workflows.

Mapping processes to spot inefficiencies.

Analyzing root causes and prioritizing changes.

Re-engineering processes to eliminate waste.

Reviewing redesigned processes with stakeholders.

Measuring performance with KPIs to ensure lasting improvement.

BPM also supports automation. By using digital tools, companies can automate routine tasks, reduce manual errors, and speed up operations. This leads to better use of resources and higher productivity.

Applications

Organizations in many industries use BPM to achieve measurable results. BPM helps companies cut costs, improve customer satisfaction, and boost employee productivity. For example, automating processes can reduce labor costs by up to 50%. Streamlining workflows can lower response times by 40%. Simplified processes can increase task completion rates by 25%.

Aspect | Business Process Management (BPM) | Other Methodologies (Lean, Six Sigma) |

|---|---|---|

Lifecycle Phases | Structured phases with continuous monitoring and optimization | Lean focuses on waste; Six Sigma uses data for quality improvement |

Measurable Outcomes | Emphasizes cost savings, operational excellence, and ongoing performance tracking through KPIs | Lean targets efficiency; Six Sigma targets defect reduction |

Nature of Process | Ongoing, repeatable, and optimized with real-time execution and monitoring | Often project-based or focused on specific improvements |

Adaptability | Agile BPM handles unforeseen scenarios and supports faster growth | Traditional methods may be less flexible |

Monitoring & Control | Continuous monitoring and control ensure sustained improvements | Improvements may be periodic or project-specific |

Example Outcomes | Cost savings, operational excellence, flexibility in unpredictable environments | Lean: efficiency; Six Sigma: quality |

BPM differs from other business process improvement methodologies because it focuses on continuous, measurable outcomes. While Lean and Six Sigma often target specific projects or problems, BPM manages processes as ongoing cycles. This means organizations can adapt quickly and keep improving over time.

Companies in banking, healthcare, manufacturing, and retail use BPM to manage complex operations. For example, a bank might use BPM to automate loan approvals, reducing wait times for customers. A hospital could use BPM to streamline patient admissions, improving care and reducing paperwork. Retailers use BPM to manage supply chains, ensuring products reach shelves faster and with fewer errors.

BPM supports long-term success by making processes more efficient, flexible, and responsive. Organizations that use BPM often see lower costs, happier customers, and more productive employees.

Comparing Methodologies

Strengths

Each business process improvement methodology offers unique strengths. Some focus on efficiency, while others emphasize quality or adaptability. The following table highlights key strengths and weaknesses of several popular approaches:

Methodology | Strengths | Weaknesses |

|---|---|---|

Lean Six Sigma | Enhances customer satisfaction, reduces costs, boosts employee engagement | Requires extensive training, depends on accurate data analysis |

Agile | Improves project visibility, accelerates time-to-market, increases customer responsiveness | May not fit rigid hierarchies, requires mindset shift |

Business Process Reengineering (BPR) | Enables breakthrough performance improvements, simplifies processes, increases agility | Employee resistance, time-consuming and disruptive |

Total Quality Management (TQM) | Improves product quality, increases customer loyalty, fosters quality culture | Needs strong leadership commitment, slow to show results |

Kaizen | Empowers employees, supports ongoing problem-solving, promotes continuous learning | Not suitable for radical or rapid transformations |

Lean Six Sigma stands out for reducing costs and improving customer satisfaction. Agile helps teams deliver results quickly and adapt to change. BPR can lead to dramatic improvements in performance. TQM builds a strong quality culture, and Kaizen encourages everyone to contribute to ongoing improvements.

Limitations

No single methodology works perfectly in every situation. Each approach has its own set of challenges. For example, Lean, Six Sigma, and Agile can fall short if organizations try to force every problem into one method. Lean may focus too much on waste reduction, while Agile teams sometimes lose sight of the bigger picture. Many organizations struggle when they do not blend these methods into a broader business strategy.

Lack of leadership commitment, which hinders driving necessary changes.

Neglecting customer focus, failing to align efforts with customer needs.

Overlooking cultural change requirements, causing resistance and hindering progress.

Overemphasis on tools and techniques rather than understanding underlying principles.

Implementing methodologies in isolation without integrating into overall business strategy.

Lack of data-driven decision-making, which impedes identifying root causes and measuring performance.

Setting unrealistic expectations about the speed or magnitude of improvements.

Organizations often see the best results when they combine methods and adapt them to their unique needs.

Best Use Cases

Industry experts recommend matching each methodology to specific business scenarios. The table below shows which contexts suit each approach best:

Methodology | Best Suited Business Scenario / Industry Context |

|---|---|

Lean Manufacturing | Manufacturing sectors aiming to reduce waste and improve efficiency. Example: Intel reduced microchip production time significantly. |

Total Quality Management (TQM) | Organizations embedding quality in all processes with employee involvement to improve customer satisfaction. |

Just-in-Time | Manufacturing processes focused on reducing inventory costs and increasing efficiency. |

Theory of Constraints | Businesses targeting systemic improvements by identifying and addressing bottlenecks to improve profitability or efficiency. |

Kaizen | Organizations of all sizes fostering continuous small improvements and cultural shifts involving all employees. |

PDCA (Plan-Do-Check-Act) | Any organization aiming for systematic continuous improvement through iterative cycles. |

Process Mapping | Businesses seeking clarity on process inefficiencies by visualizing workflows and identifying improvement areas. |

Kanban | Teams wanting to improve workflow, reduce cycle time, and ensure continuous delivery using visual management tools. |

People, Process, Technology Framework | Organizations undergoing transformation aiming to align workforce, optimize processes, and leverage technology effectively. |

5S Method | Manufacturing, warehousing, and physical workspaces emphasizing organization, cleanliness, safety, and efficiency. |

SIPOC Analysis | Initial stages of complex or cross-functional process improvements requiring a high-level understanding of process components. |

Value Stream Mapping | Manufacturing, logistics, and service processes aiming to reduce waste, improve flow, and enhance customer value. |

Selecting the right methodology depends on the organization’s goals, industry, and readiness for change. Teams should assess their needs and choose the approach that aligns best with their objectives.

Choosing the Right Approach

Assessing Needs

Organizations must first understand their unique needs before selecting a business process improvement methodology. Leaders often start by examining current workflows and identifying areas that slow down progress or create waste. They use key performance indicators (KPIs) and data to measure how well processes perform. This helps them decide if they need to focus on efficiency, quality, or another priority.

Leaders review the organization's business needs and existing processes.

Teams identify bottlenecks or problem areas that require attention.

Data and KPIs reveal which processes need improvement.

The size and nature of the organization influence the choice of methodology.

Aligning the approach with the organization's vision and mission ensures improvements support long-term goals.

Selecting the right methodology also depends on the organization's culture and readiness for change. Some teams may prefer gradual improvements, while others need bold changes. Leaders should consider workforce needs and how much change employees can handle. Change management plays a key role in supporting these efforts by encouraging engagement and clear communication.

Aligning with Goals

Aligning process improvement efforts with organizational goals increases the chances of success. When leaders connect improvement projects to the company's mission and vision, teams stay focused on what matters most. For example, Siemens achieved a 30% efficiency gain by combining improvement methods under strong leadership and clear guidelines. This approach ensures that every project supports the company's strategic pillars.

Organizations translate their mission and core values into specific strategies. These strategies break down into measurable objectives and projects. Leaders use performance measures to track progress and make sure improvements lead to better results. This alignment helps prioritize the most impactful projects and ensures resources go where they are needed most.

Methodology selection should match organizational goals, culture, and process type.

Aligning with strategic objectives improves efficiency, quality, and customer satisfaction.

Leaders must address challenges like resistance to change and sustaining improvements.

KPIs linked to improvement goals help track and evaluate success.

Combining methods, such as Lean Six Sigma, can work well if they remain aligned with goals.

Continuous evaluation and refinement keep organizations on track and support lasting success.

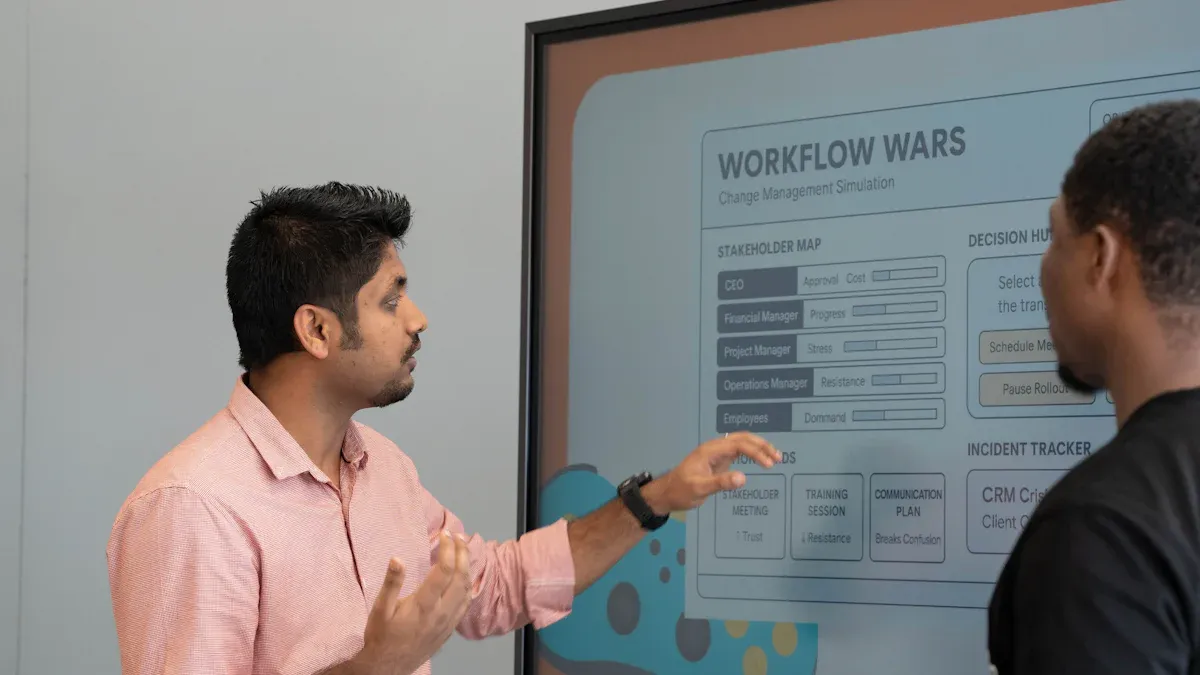

Stakeholder Involvement

Stakeholder involvement plays a critical role in successful process improvement. When leaders include employees, managers, and even customers in the process, they reduce resistance and build support. Research shows that lack of stakeholder engagement often leads to failure, as people may feel threatened by imposed changes.

Identify and involve all relevant stakeholders, including internal teams and external clients.

Communicate early and clearly about how stakeholders will participate.

Use stakeholder analysis to focus on gaining support and approval.

Involve leadership to present a strong business case.

Maintain engagement to ensure stakeholders understand the benefits and reasons for change.

Listen to stakeholder concerns to make better decisions and improve processes.

A phased approach works well:

Engage stakeholders early to define success and align on the impact of changes.

Involve them in planning and communication to support the transition.

Keep them engaged to ensure ownership and long-term adoption.

Ongoing engagement fosters trust and helps organizations achieve sustainable improvements. In healthcare, for example, continuous stakeholder involvement supported by technology leads to better outcomes and higher satisfaction. By prioritizing feedback and training, organizations address complex needs and ensure process improvements succeed.

Implementing Business Process Improvement Methodologies

Preparation

Successful implementation of Business Process Improvement Methodologies begins with careful preparation. Organizations must identify which process needs improvement. Teams often focus on areas such as delivery times, billing cycles, or production efficiency. They outline and map the current process using flowcharts or diagrams. This step helps everyone understand the sequence of tasks and who is responsible for each part.

Teams gather relevant data about the current process. They look at key performance indicators like quality, time, and input/output ratios. Reliable and accessible data is essential. After collecting data, teams analyze it to find bottlenecks and inefficiencies. They use methods such as team input and cause-and-effect analysis to validate root causes.

Collaboration is important during preparation. Teams work together to identify potential solutions. They redesign process steps, conduct impact and risk analyses, and prepare resources. A strong business case helps gain stakeholder buy-in. Planning and careful implementation ensure a smooth roll-out. Clear communication and adequate testing reduce confusion and errors.

Organizations set up measurement systems with KPIs to monitor the impact of changes. These systems track cost savings, time savings, and satisfaction levels for both customers and employees. Continuous monitoring and evaluation help sustain improvements. Employees at all levels participate, fostering a culture of ongoing enhancement.

Tip: Prioritize improvements by addressing the most critical issues first. Implement changes one at a time to measure impact effectively.

Preparation Steps:

Identify and select the process to improve.

Map the current process using diagrams.

Gather and analyze relevant data.

Locate bottlenecks and validate root causes.

Collaborate to identify solutions and redesign steps.

Prepare resources and gain stakeholder buy-in.

Plan and implement changes with clear communication.

Set up KPIs and monitor results.

Continuously evaluate and adjust improvements.

Clients at systems and teams have followed these steps to achieve measurable improvements. For example, a client in manufacturing improved delivery times by mapping processes and analyzing data, leading to faster production and higher customer satisfaction.

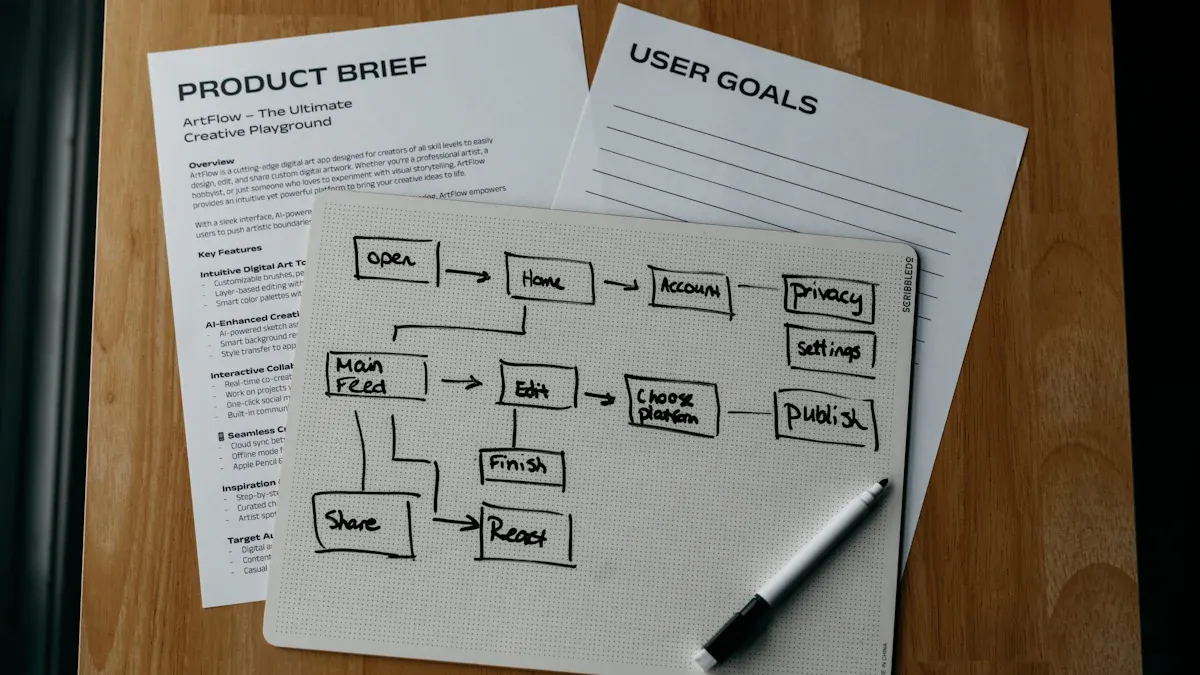

Process Mapping

Process mapping is a key technique in Business Process Improvement Methodologies. Teams use process mapping to visualize workflows and identify inefficiencies. Common methods include flowcharts, swimlane diagrams, value stream maps, BPMN diagrams, SIPOC diagrams, and hierarchical process maps.

Each mapping method serves a different purpose. Flowcharts show sequential steps. Swimlane diagrams clarify roles and responsibilities. Value stream maps help reduce waste, especially in manufacturing and supply chains. BPMN diagrams use standardized symbols for technical modeling. SIPOC diagrams provide high-level overviews of processes.

Modern process mapping software makes these tasks easier. Tools like Kissflow offer drag-and-drop editors and support automation. Reporting and analytics features help teams identify inefficiencies and monitor performance. Real-time collaboration and integration with other systems improve accuracy and speed.

Process mapping helps teams standardize procedures, document knowledge, and support training. It also improves communication by making workflows visible to everyone. Systems and teams have used process mapping to streamline operations. For instance, a client in healthcare used swimlane diagrams to clarify responsibilities, reducing errors and improving patient care.

Effective Process Mapping Tools:

Flowcharting

BPMN (Business Process Model and Notation)

Value stream mapping

Swimlane diagrams

Mind mapping

SIPOC diagrams

Data flow diagrams

Methodology Selection

Selecting the right process improvement methodology is crucial for success. Organizations must align the chosen methodology with their goals. For example, Agile works well for fast delivery, while Six Sigma focuses on error reduction. Organizational culture also matters. Kaizen requires employee involvement, while other methods may use a top-down approach.

Teams evaluate process complexity. Lean or SIPOC suits complex supply chains. Available resources, such as data and analytics capabilities, influence the choice. Six Sigma needs strong data skills, while simpler methods like 5 Whys require less expertise. Timelines and urgency also play a role. PDCA or Agile allow quick improvements, while more rigorous methods may take longer.

Clear, measurable goals help guide methodology selection. Teams form cross-functional groups to bring diverse perspectives. They analyze current workflows to understand baseline performance and pain points. Pilot tests validate assumptions and minimize risks. Defined performance metrics measure outcomes. Successful changes are scaled up with detailed plans and training. Continuous feedback loops sustain improvements.

Clients at systems and teams have considered these factors when choosing methodologies. A client in retail selected Lean to reduce waste and improve efficiency, resulting in lower costs and better customer service.

Factors to Consider When Selecting a Methodology:

Alignment with organizational goals

Organizational culture and employee involvement

Process complexity

Available resources and data capabilities

Timelines and urgency

Clear, measurable goals

Cross-functional team involvement

Pilot testing and risk validation

Performance metrics and continuous feedback

Callout: Involve employees and stakeholders in decision-making. Open communication and recognition of contributions increase the chances of successful adoption and sustained improvement.

Training Teams

Training teams forms a critical step in successful process improvement. Well-prepared teams can adapt to new methods and drive lasting change. Organizations start by identifying the specific process that needs improvement. They collect data on current performance, such as duration, costs, and error rates. Setting SMART goals—Specific, Measurable, Achievable, Relevant, and Time-bound—gives teams clear objectives.

Leaders play an active role in supporting training. They answer questions and encourage suggestions. Teams work best when members come from different departments. Each person has a defined role and the authority to make decisions. A detailed improvement plan outlines timelines and assigns responsibilities.

Best practices for training teams include:

Gather data on current performance.

Set SMART goals for the project.

Engage team members from various departments.

Define roles and give authority to act.

Develop a detailed plan with clear timelines.

Use change management strategies to reduce resistance.

Monitor progress and adjust as needed.

Standardize new procedures and provide ongoing training.

Tip: Celebrate small wins to keep teams motivated. Remove barriers like time or resource shortages so teams can focus on improvement. Empower teams to act quickly without waiting for too many approvals.

Organizations also encourage diverse solutions. Teams look for ways to improve customer experience, employee morale, and engagement. Leaders remain patient and supportive, knowing that cultural change takes time. Ongoing coaching and training help embed continuous improvement into the company culture. This approach boosts productivity, creativity, and teamwork.

Execution

Execution turns plans into action. Teams implement the chosen process improvements step by step. Clear communication ensures everyone understands their tasks. Leaders provide support and resources to remove obstacles.

Teams follow the improvement plan closely. They use checklists and schedules to track progress. Regular meetings help teams share updates and solve problems quickly. Leaders encourage feedback and adjust the plan if needed.

Change management plays a key role during execution. Teams address resistance by explaining the benefits of new processes. Leaders listen to concerns and provide extra training when necessary. Empowered teams act quickly and make decisions on the spot.

Organizations document each change. They update procedures and train staff on new methods. Standardizing successful changes helps maintain consistency. Teams celebrate milestones to keep motivation high.

Note: Execution works best when teams stay flexible. They should be ready to adapt if unexpected challenges arise.

Monitoring

Monitoring measures the success of process improvements. Teams track key metrics to see if changes deliver the expected results. Common metrics include cycle time, yield rate, on-time delivery, defect rate, and cost per unit produced.

Metric Category | Metric Name | Description | Example |

|---|---|---|---|

Operational Performance Indicators | Cycle Time | Total time to complete a task or process from start to finish. | Car assembly taking 8 hours from start to finish. |

Yield Rate | Percentage of compliant parts produced compared to raw materials used. | 950 compliant items out of 1,000 parts = 95% yield rate. | |

On Time Delivery (OTD) | Percentage of orders delivered on time. | 180 orders delivered on time out of 200 = 90% OTD. | |

Quality Indicators | Defect Rate | Percentage of defective parts out of total produced. | 200 defective units out of 10,000 = 2% defect rate. |

Scrap Rate | Quantity of discarded or unusable items after production. | 500 rejected units out of 10,000 = 5% scrap rate. | |

Equipment Efficiency Indicators | Overall Equipment Effectiveness (OEE) | Measures machine performance based on availability, performance, and quality. | Machine operating 80% time, 90% performance, 95% quality = 68.4% OEE. |

Financial Metrics | Cost per Unit Produced | Total production cost divided by number of units produced. | $50,000 cost for 5,000 units = $10 per unit. |

Return on Investment (ROI) | Benefits from improvement projects compared to costs incurred. | $10,000 investment yielding $15,000 gains = 50% ROI. |

Teams also monitor error rates, resource utilization, cost savings, and revenue growth. Customer satisfaction and employee engagement provide insight into the impact of changes. Compliance and risk management metrics help organizations avoid penalties.

Key metrics such as cycle time, error rates, and ROI show if process improvements work. Studies show that reducing cycle times can boost efficiency by up to 50%. Higher employee engagement leads to better performance and profits.

Teams review these metrics regularly. They compare results before and after changes. If goals are not met, teams adjust their approach. Continuous monitoring ensures improvements last and supports ongoing success.

Overcoming Challenges

Organizations often face several obstacles when implementing process improvement initiatives. These challenges can include resistance to change, limited resources, unclear goals, and difficulty measuring progress. Overcoming these barriers requires a structured approach and a commitment to continuous improvement.

Common Challenges and Solutions

Resistance to Change

Employees may feel uncertain or threatened by new processes. Leaders can reduce resistance by involving team members early and encouraging open communication. When employees help shape changes, they feel more ownership and less anxiety.Limited Resources

Many organizations struggle with tight budgets and limited staff. Prioritizing projects with the highest impact helps optimize available resources. Leaders should focus on changes that deliver the most value first.Lack of Clear Communication

Misunderstandings can slow down or derail improvement efforts. Clear and consistent communication builds trust and keeps everyone aligned. Leaders should explain the reasons for change and how it benefits both the organization and its employees.Difficulty Measuring Success

Without clear metrics, teams may not know if improvements work. Setting measurable goals and tracking key performance indicators (KPIs) allows organizations to monitor progress and adjust as needed.Sustaining Improvements

Some teams see early gains but struggle to maintain them. Regular review sessions and feedback mechanisms help identify what works and what needs adjustment. Celebrating small wins boosts morale and reinforces positive changes.

Proven Strategies for Success

Organizations can use several strategies to overcome these challenges:

Prioritize High-Impact Projects

Focus on changes that offer the greatest benefits. This approach ensures that limited resources are used wisely.Leverage Technology

Automate routine tasks and streamline workflows with digital tools. Technology can reduce manual errors and free up staff for higher-value work.Involve Employees Actively

Encourage team members to participate in planning and decision-making. Active involvement reduces resistance and fosters a sense of ownership.Communicate Clearly and Consistently

Share updates regularly and explain the purpose behind each change. Consistent messaging helps align goals across the organization.Provide Training and Support

Offer training sessions and ongoing support to help employees adapt to new processes. Well-trained teams feel more confident and capable.Implement Feedback Mechanisms

Create channels for employees to share feedback and suggest improvements. Listening to feedback allows organizations to make timely adjustments.Celebrate Small Wins

Recognize and reward progress, even if it is incremental. Celebrating achievements keeps teams motivated and engaged.Conduct Regular Review Sessions

Schedule regular meetings to assess progress and identify areas for further improvement. These sessions help sustain momentum.Empower Change Champions

Identify and support individuals who can motivate and guide others through the change process. Change champions act as role models and sources of encouragement.Use Process Mapping and Stakeholder Engagement

Visualize workflows to spot inefficiencies and involve stakeholders to ensure everyone understands and supports the changes.

Tip: Structured approaches like Lean, Six Sigma, BPM, PDCA, Kaizen, and TQM provide proven frameworks for overcoming challenges. These methods encourage organizations to analyze problems, involve teams, communicate changes, and monitor results for continuous improvement.

Tools and Techniques

Technique | Purpose | Benefit |

|---|---|---|

5 Whys Analysis | Identify root causes of problems | Prevents recurring issues |

Process Mapping | Visualize and clarify workflows | Reveals bottlenecks and inefficiencies |

DMAIC Cycle | Guide structured problem-solving | Ensures thorough analysis and control |

PDCA Cycle | Test and implement improvements iteratively | Supports continuous learning and growth |

Organizations that use these strategies and tools can overcome common obstacles and achieve lasting improvements. Regular monitoring, open communication, and a focus on people make the difference between short-term gains and long-term success.

Sustaining Success

Continuous Improvement

Continuous improvement helps organizations maintain progress after initial changes. Teams look for small ways to make processes better every day. This approach keeps the organization flexible and ready for new challenges. Leaders encourage employees to share ideas for improvement. They set up regular meetings to review progress and discuss new suggestions.

Many organizations use tools like suggestion boxes, daily stand-up meetings, or improvement boards. These tools help teams track ideas and measure results. Employees feel valued when leaders listen to their feedback. This culture of improvement leads to higher engagement and better performance.

Tip: Small changes add up over time. Teams that focus on daily improvements often see big results in the long run.

Change Management

Change management supports lasting success by guiding people through transitions. Leaders explain why changes are needed and how they will help the organization. Clear communication reduces confusion and builds trust. Training sessions help employees learn new skills and adapt to new processes.

Successful change management includes several steps:

Communicate the vision and benefits of the change.

Involve employees in planning and decision-making.

Provide training and resources for new tasks.

Address concerns and answer questions quickly.

Monitor progress and adjust plans as needed.

A structured approach helps teams overcome resistance. Leaders who support their teams during change create a positive environment. Employees feel more confident and willing to try new ways of working.

Recognition

Recognition motivates employees to keep improving. Leaders celebrate both small and large achievements. They thank teams for their hard work and highlight successful projects. Public recognition, such as awards or shout-outs in meetings, boosts morale.

Organizations use different ways to recognize contributions:

Verbal praise during team meetings

Written notes or emails of appreciation

Certificates or awards for outstanding work

Sharing success stories in company newsletters

Recognizing effort encourages employees to stay engaged. It also helps build a culture where everyone feels valued and motivated to contribute.

When leaders make recognition a regular practice, employees feel proud of their work. This pride leads to higher job satisfaction and better results for the organization.

Technology and Tools

Technology plays a vital role in sustaining process improvements. Organizations use digital tools to automate tasks, monitor progress, and support collaboration. These solutions help teams maintain gains and adapt to new challenges.

Many companies rely on process automation software. These platforms handle repetitive tasks, reduce errors, and free employees for higher-value work. Automation improves speed and consistency. For example, workflow automation tools route documents, approve requests, and track deadlines. Teams see faster results and fewer mistakes.

Data analytics platforms provide real-time insights. They collect and analyze performance metrics, such as cycle time and defect rates. Leaders use dashboards to spot trends and identify areas for improvement. Analytics help organizations make informed decisions and respond quickly to changes.

Collaboration tools connect team members across departments. Platforms like project management software, shared document editors, and instant messaging apps keep everyone aligned. Teams share updates, assign tasks, and solve problems together. These tools support transparency and accountability.

Cloud-based solutions offer flexibility and scalability. Organizations store data securely and access it from anywhere. Cloud platforms integrate with other systems, making it easier to manage complex workflows. Teams can scale resources up or down as needed.

Mobile applications allow employees to track progress and report issues on the go. Field workers use mobile devices to update status, capture photos, and communicate with managers. This mobility increases responsiveness and supports continuous improvement.

Note: Choosing the right technology depends on organizational needs, budget, and existing systems. Leaders should evaluate tools for ease of use, integration, and support.

The table below compares common technology types used in process improvement:

Technology Type | Main Function | Example Benefit |

|---|---|---|

Automation Software | Automates routine tasks | Reduces errors, saves time |

Data Analytics | Tracks and analyzes metrics | Informs decisions, spots trends |

Collaboration Tools | Connects team members | Improves communication |

Cloud Platforms | Stores and shares data | Enables remote access |

Mobile Applications | Supports field operations | Increases flexibility |

Organizations benefit from technology in several ways:

Faster response to problems

Improved accuracy and consistency

Better communication among teams

Easier tracking of progress and results

Greater adaptability to change

Technology supports the long-term success of process improvement efforts. When organizations invest in the right tools, they build a foundation for continuous growth and innovation.

Selecting the right business process improvement methodology shapes long-term success. Teams that assess their workflows and take action see real progress. Every organization can build a culture of continuous improvement by making small changes each day.

Continuous improvement starts with one step.

Take action now—review your processes and choose a method that fits your goals.

Ready to learn more or need expert guidance? Contact us to start your journey toward lasting improvement.

FAQ

What is the main goal of business process improvement methodologies?

The main goal is to help organizations work more efficiently. These methods reduce waste, improve quality, and increase customer satisfaction. Teams use them to find problems and make changes that last.

How often should a company review its processes?

Companies should review processes regularly. Many experts suggest doing this at least once a year. Regular reviews help teams spot new problems and keep improvements on track.

Can small businesses use these methodologies?

Yes, small businesses can use these methods. They can start with simple tools like process mapping or PDCA. Even small changes can lead to big results over time.

What is the difference between Lean and Six Sigma?

Lean focuses on removing waste and speeding up processes. Six Sigma aims to reduce errors and improve quality using data. Many companies combine both for better results.

Do teams need special training to use these methods?

Most teams need some training. Training helps everyone understand the steps and tools. Many organizations offer workshops or online courses to build these skills.

How can technology support process improvement?

Technology helps teams track progress, automate tasks, and analyze data. Tools like workflow software and dashboards make it easier to see results and find areas to improve.

What should a company do if employees resist change?

Leaders should explain the benefits clearly and involve employees in planning. Listening to concerns and offering support can help reduce resistance. Recognition of effort also encourages acceptance.

Are these methodologies only for manufacturing?

No, these methods work in many industries. Healthcare, banking, retail, and education all use process improvement to boost performance and service quality.