How to Use Lean Thinking to Eliminate Waste and Boost Efficiency

Lean Thinking serves as a powerful framework for reducing waste and boosting efficiency across industries. By focusing on delivering value to customers, it helps organizations streamline their processes and eliminate unnecessary steps. This approach emphasizes continuous improvement, where small, incremental changes lead to significant transformations over time.

Organizations that adopt Lean principles often see measurable results. Case studies reveal how businesses across sectors have successfully applied Lean Thinking to enhance efficiency and reduce waste. Teams and systems that embrace this mindset foster collaboration and shared ownership, creating a culture of sustained growth. For those seeking to improve business management or sales processes, Lean Thinking provides the knowledge needed to achieve lasting success.

Key Takeaways

Lean Thinking helps give customers what they need by cutting waste.

Knowing what customers want is key to using time and tools well.

Drawing out the steps shows problems and helps fix them.

Smooth steps make sure products or services are delivered without stops.

A pull system matches making things to what customers actually need.

Small changes over time help businesses improve and stay successful.

Getting workers involved builds teamwork and makes them feel responsible.

Watching important numbers shows how well things are working and what to fix.

Core Principles of Lean Thinking

Defining Value for the Customer

Lean Thinking begins with understanding what the customer values most. This principle emphasizes identifying the specific products or services that meet customer needs and expectations. Organizations must focus on delivering what the customer perceives as valuable while eliminating activities that do not contribute to this goal. For example, a manufacturing company might prioritize reducing defects in its products, as customers value reliability and quality.

By defining value, teams can align their efforts toward creating offerings that resonate with their target audience. This clarity ensures that resources are allocated efficiently, avoiding unnecessary costs or delays. Systems that adopt this principle often see improved customer satisfaction and loyalty, as their processes are tailored to meet customer demands effectively.

Mapping the Value Stream

Mapping the value stream involves visualizing all the steps required to deliver value to the customer. This process helps organizations identify wasteful activities and streamline their operations. Tools like Value Stream Mapping (VSM) play a crucial role in this step. VSM combines value analysis, which distinguishes value-adding steps from non-value-adding ones, with flow analysis, which measures the time spent on each step. This dual approach enables teams to pinpoint inefficiencies and optimize their workflows.

For instance, a software development team might use VSM to analyze its coding and testing processes. By identifying bottlenecks or redundant steps, the team can implement changes that enhance productivity and reduce lead times. Mapping the value stream not only improves operational efficiency but also ensures that every action contributes to delivering customer value.

Creating Flow in Processes

Creating flow ensures that value moves smoothly through the system without interruptions or delays. This principle focuses on eliminating wasteful activities that disrupt the seamless delivery of products or services. Key steps to creating flow include understanding process flow templates, identifying Key Process Input Variables (KPIVs) and Key Process Output Variables (KPOVs), and implementing a streamlined process flow.

Challenges may arise when attempting to create flow, such as resistance to change or difficulty in identifying inefficiencies. However, organizations that succeed in this step often experience significant improvements in efficiency and compliance. For example, a healthcare system might redesign its patient admission process to reduce waiting times and enhance service delivery. By addressing inefficiencies, the system ensures that patients receive timely care, aligning with the principles of Lean Thinking.

Using a Pull System

A pull system operates by producing goods or services based on actual customer demand rather than relying on forecasts. This approach ensures that resources are utilized efficiently, aligning production with real-time needs. Unlike traditional push systems, which rely on predicted demand and often lead to overproduction, a pull system minimizes waste and enhances responsiveness.

Key advantages of a pull system include:

Enhanced customization capabilities, allowing teams to tailor products or services to specific customer requirements.

Improved cash flow management by reducing the capital tied up in excess inventory.

Greater flexibility to adapt to changing market demands.

The system works by triggering production or stocking through real-time demand signals. For example, in a retail setting, inventory replenishment occurs only when a product is sold, ensuring that stock levels remain optimal. This method aligns closely with just-in-time manufacturing principles, which aim to produce only what is needed, when it is needed.

Organizations adopting a pull system often experience the following benefits:

Reduced Inventory Costs: By minimizing holding costs, teams can allocate resources more effectively while ensuring timely order fulfillment.

Just-in-Time Delivery: Synchronizing production with actual demand reduces the risk of excess stock and storage issues.

Waste Reduction: Producing only what is required eliminates overproduction and associated inefficiencies.

For instance, a manufacturing team implementing a pull system might use Kanban boards to visualize workflows and manage inventory levels. This approach ensures that production aligns with customer orders, reducing delays and improving overall efficiency. By adopting a pull system, teams can create a leaner, more adaptable operation that prioritizes customer satisfaction.

Pursuing Continuous Improvement

Continuous improvement focuses on making ongoing, incremental changes to processes, systems, and workflows. This principle lies at the heart of lean thinking, driving organizations to consistently enhance their operations and deliver greater value to customers. Teams that embrace this mindset prioritize learning, experimentation, and adaptability.

Real-world examples highlight the effectiveness of continuous improvement. Toyota, for instance, employs techniques like Kaizen, Kanban, and just-in-time manufacturing to refine its processes. These methods have helped Toyota become the world's leading auto manufacturer. Similarly, Amazon's commitment to continuous experimentation and customer-centricity has positioned it as one of the most valuable companies globally.

Organization | Continuous Improvement Techniques | Outcomes |

|---|---|---|

Toyota | Just-in-Time (JIT), Kaizen, Kanban, Andon | Became the number-one auto manufacturer globally |

Amazon | Continuous experimentation, customer-centricity | One of the world's largest and most valuable companies |

Apple | Iterative design, user-centered research | Largest company in the world by market cap |

GE | Six Sigma, Lean Manufacturing | Competitive success across industries |

McDonald's | Standardization, menu innovation | Global leader in the fast-food industry |

Intel | Intel Quality System, customer input | Largest player in the CPU market |

IBM | Lean Six Sigma, Agile practices | Technology and consulting industry leader |

Continuous improvement fosters a culture of innovation and adaptability. Teams that adopt this approach often see enhanced efficiency, reduced costs, and improved customer satisfaction. By focusing on small, consistent changes, organizations can achieve continual improvement and long-term success.

Identifying and Eliminating Waste

The Seven Wastes in Lean Thinking

Lean identifies seven types of waste that hinder efficiency and reduce value delivery. These wastes occur across industries and processes, impacting productivity and customer satisfaction. Understanding these categories helps teams focus on waste elimination:

Defects: Errors requiring rework or correction, such as software bugs or incorrect medication administration. These issues waste time and materials.

Transportation: Unnecessary movement of items, like inefficient delivery routes or moving patients unnecessarily, which wastes effort and increases costs.

Waiting: Idle time for inventory, customers, or processes. Examples include patients waiting in healthcare facilities or manufacturing delays due to missing components.

Motion: Excessive movement by people or tools, such as searching for misplaced items or working in poorly organized spaces.

Overproduction: Producing more than needed, leading to excess inventory that ties up resources and creates storage challenges.

Overprocessing: Performing unnecessary work that does not add value, such as redundant approvals or excessive polishing of a product.

Inventory: Holding more stock than required, which consumes space and capital without immediate benefit.

By addressing these wastes, organizations can streamline operations and enhance efficiency.

Recognizing Waste in Your Processes

Identifying waste requires a structured approach. Value Stream Mapping (VSM) serves as a powerful tool for this purpose. It visually represents the flow of materials and information within a process, distinguishing between value-added and non-value-added activities. Teams can analyze current workflows, document inefficiencies, and design improved systems.

For example, a manufacturing team might use VSM to track the journey of raw materials through production. By identifying bottlenecks or redundant steps, they can develop strategies to optimize the process. Engaging frontline workers in this analysis fosters collaboration and encourages a culture of continuous improvement. Starting with the end customer in mind ensures that every change aligns with delivering value.

Practical Examples of Waste Elimination

Practical applications of waste elimination demonstrate its transformative potential. In healthcare, reducing patient waiting times improves service delivery and satisfaction. A hospital might redesign its admission process to minimize delays, ensuring patients receive timely care. Similarly, in manufacturing, implementing a pull system reduces overproduction by aligning output with actual demand.

Another example involves organizing workspaces using the 5S methodology. By sorting and standardizing tools, teams eliminate unnecessary motion and improve efficiency. For instance, a factory team might label and arrange tools for easy access, reducing time spent searching for equipment.

In software development, addressing defects early in the coding process prevents costly rework later. Teams adopting Agile practices often conduct regular reviews to identify and resolve issues promptly. These examples highlight how waste elimination enhances productivity and customer satisfaction across industries.

Practical Applications of Lean Thinking

Conducting Value Stream Mapping

Value stream mapping serves as a foundational tool in lean thinking. This method allows teams to visualize their processes, identify inefficiencies, and implement improvements. The steps involved in value stream mapping include:

Define the scope of the process.

Identify the steps in the process.

Measure the value-added and non-value-added steps.

Analyze the flow of the process.

Identify opportunities for improvement.

Implement improvements and measure the results.

By following these steps, teams can uncover hidden inefficiencies and streamline workflows. For example, a manufacturing team might use value stream mapping to analyze production bottlenecks. This approach often leads to benefits such as improved customer service, reduced inventory, and increased efficiency. Teams that adopt this method also experience better decision-making and lower costs, making it a critical component of lean practices.

Implementing 5S for Organization

The 5S methodology enhances workplace organization and efficiency by focusing on five key steps: Sort, Straighten, Shine, Standardize, and Sustain. Each step contributes to a more structured and productive environment. The table below outlines the advantages of each step:

Step | Key Advantages |

|---|---|

Sort | - More organized workspaces |

Straighten | - Less worker fatigue |

Shine | - Less buildup of grease |

Standardize | - Improved consistency |

Sustain | - Sense of empowerment |

For instance, a factory team implementing 5S might start by sorting tools and equipment to eliminate unnecessary items. This step reduces clutter and improves workflow. Sustaining these practices fosters a culture of continual improvement, ensuring long-term success.

Using Kaizen for Continuous Improvement

Kaizen, a cornerstone of lean thinking, emphasizes continuous improvement through small, incremental changes. Teams that adopt kaizen focus on refining processes to enhance efficiency and reduce waste. Examples of kaizen initiatives include inventory control techniques like Just-in-Time (JIT) and the use of Kanban boards for workflow management. JIT minimizes inventory holding costs by receiving materials only when needed, while Kanban boards improve transparency and prevent bottlenecks.

For example, a software development team might use Kanban boards to track tasks and limit work in progress. This approach ensures that resources are allocated effectively, leading to faster project completion. Similarly, a retail business might adopt JIT to align inventory levels with customer demand, reducing storage costs and waste. By embracing kaizen, teams can achieve continual improvement and deliver greater value to their customers.

Leveraging Kanban for Workflow Management

Kanban offers a practical approach to managing workflows and improving productivity. This system uses visual boards to represent tasks, making it easier for teams to monitor progress and identify inefficiencies. By implementing Kanban, organizations can streamline their processes and enhance collaboration.

Kanban boards provide several benefits for workflow management:

Improved Workflow Visualization: Teams gain a clear view of tasks at every stage. This transparency helps identify bottlenecks and ensures smooth task progression.

Increased Focus and Reduced Multitasking: Limiting the number of tasks in progress encourages team members to concentrate on one task at a time, reducing distractions.

Faster Task Completion: The pull system in Kanban allows team members to take on new tasks only when they are ready, ensuring steady progress.

Enhanced Team Collaboration: A centralized platform fosters accountability and transparency, enabling better communication among team members.

Continuous Improvement: Regular reviews of the board help teams identify inefficiencies and refine their workflows over time.

For example, a software development team might use a Kanban board to track coding, testing, and deployment tasks. Each task moves through columns labeled "To Do," "In Progress," and "Completed." This setup ensures that team members stay aligned and focus on delivering value efficiently. By adopting Kanban, teams can create a structured process that supports continuous improvement and effective management.

Monitoring and Measuring Progress

Monitoring and measuring progress are essential for ensuring the success of Lean Thinking initiatives. Teams must track key metrics to evaluate performance and identify areas for improvement. These metrics provide valuable insights into the efficiency and effectiveness of processes.

The most useful metrics for monitoring progress include:

Throughput: This metric measures production capabilities and capacity utilization. It helps teams understand how much work they can complete within a specific timeframe.

Cycle Times: This metric tracks the time taken to complete a process from start to finish. It highlights bottlenecks and delays, enabling teams to address inefficiencies.

Efficiency Metrics: These metrics focus on the relationship between input and output. They are crucial for identifying waste and optimizing resource utilization.

For instance, a manufacturing team might monitor cycle times to identify delays in assembly lines. By analyzing this data, they can implement changes to reduce lead times and improve overall efficiency. Similarly, a healthcare system might track throughput to evaluate patient flow and optimize resource allocation.

Regularly reviewing these metrics ensures that teams stay aligned with their goals. It also fosters a culture of accountability and continuous improvement. By focusing on measurable outcomes, organizations can refine their processes and achieve sustainable success.

Real-World Applications of Lean Thinking

Lean in Manufacturing

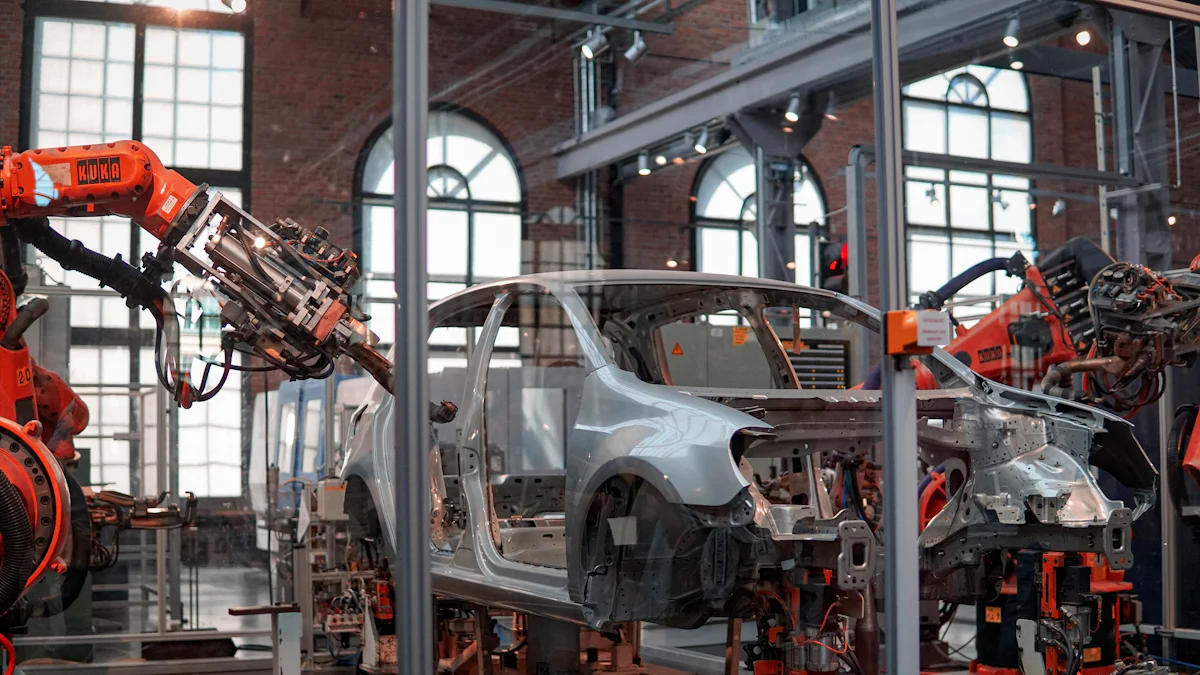

Manufacturing industries have long embraced lean principles to enhance efficiency and reduce waste. By focusing on streamlining processes and eliminating non-value-added activities, these industries have achieved remarkable results.

FedEx Express improved aircraft maintenance efficiency by introducing milestones in their C-check process. This change increased annual C-checks from 14 to 30 while reducing man-hours from 32,715 to 21,535.

Nike developed the Manufacturing Index to minimize waste and miscommunication across 800 factories. They implemented just-in-time production to reduce excess inventory.

Harley-Davidson utilized Total Productive Maintenance and lean tools like kaizen to enhance productivity and optimize inventory management.

John Deere implemented automated quality control systems to identify defects quickly and improve production processes.

Kimberly-Clark automated their transportation management system, reducing operational clicks and improving efficiency.

Intel applied lean techniques to reduce works-in-process and waste while maintaining high product quality.

Ford adopted continuous improvement methodologies like kaizen and Six Sigma to enhance assembly line efficiency and product quality.

These examples demonstrate how manufacturing teams can use lean strategies to optimize workflows, reduce costs, and deliver high-quality products to customers.

Lean in Healthcare

Healthcare systems have adopted lean thinking to improve patient care and operational efficiency. By focusing on patient value and streamlining processes, healthcare teams have achieved significant improvements.

Virginia Mason Medical Center implemented lean principles to enhance patient flow and reduce errors. This approach resulted in shorter wait times for appointments and procedures, improved safety through fewer medical errors, and cost savings due to better resource utilization.

Healthcare organizations often map the patient journey to identify waste and streamline processes. For example, aligning healthcare workflows ensures smooth patient flow and minimizes delays. A pull system, where services are provided based on patient readiness, further reduces wait times. Continuous improvement remains a core principle, enabling healthcare teams to adapt to changing patient needs.

These strategies not only improve patient outcomes but also create more efficient and responsive healthcare systems.

Lean in Software Development

Software development teams face unique challenges when applying lean principles, but the benefits often outweigh the difficulties. Lean thinking helps these teams focus on delivering value to end users while minimizing waste.

Challenges include specialized hiring requirements, delayed decision-making, and the risk of over-simplification. Teams may also struggle with limited resources, organizational changes, and aligning key performance indicators (KPIs) with project goals. Despite these obstacles, lean principles offer significant advantages:

Cost savings through waste elimination and reduced maintenance costs.

Enhanced efficiency by streamlining workflows and focusing on valuable features.

A customer-centric approach that aligns development with user needs, boosting satisfaction.

Fostered collaboration through teamwork and effective communication.

Continuous improvement through regular process reviews and enhancements.

For example, software teams often use Kanban boards to visualize workflows and limit work in progress. This approach ensures steady progress and prevents bottlenecks. By focusing on delivering high-value products, software teams can achieve greater efficiency and customer satisfaction.

Lean in Small Businesses

Small businesses can benefit significantly from Lean Thinking by streamlining operations and reducing waste. These principles, often associated with large organizations, are equally effective for smaller teams and systems. By focusing on customer value and operational efficiency, small businesses can achieve sustainable growth and improved productivity.

One of the most impactful ways small businesses can adopt Lean Thinking is by engaging employees in continuous improvement. Employees often have firsthand knowledge of inefficiencies in daily operations. Regular feedback loops allow them to identify waste and suggest practical solutions. For example, a local bakery might involve its staff in brainstorming ways to reduce ingredient waste or improve workflow in the kitchen. This approach not only enhances efficiency but also fosters a sense of ownership and collaboration among team members.

The "5S" system offers another practical tool for small businesses. This method focuses on organizing the workspace through five steps: Sort, Set in Order, Shine, Standardize, and Sustain. A small auto repair shop, for instance, could use 5S to arrange tools systematically, ensuring mechanics spend less time searching for equipment. Clean and organized workspaces also reduce errors and improve safety, creating a more productive environment.

Implementing a pull system helps small businesses align production with actual customer demand. This approach minimizes overproduction and excess inventory, which can strain limited resources. A boutique clothing store, for example, might restock items only when customers purchase them, avoiding the costs of holding unsold inventory. This system ensures that resources are used efficiently while meeting customer needs promptly.

Creating a culture of continuous learning is essential for long-term success. Training employees on Lean tools and encouraging ongoing process enhancement equips teams to adapt to changing circumstances. A small IT consulting firm might hold regular workshops to teach staff about Kanban boards or value stream mapping. These sessions empower employees to identify inefficiencies and implement improvements, driving consistent progress.

Lean Thinking enables small businesses to operate more effectively by focusing on customer value, engaging employees, and optimizing workflows. Teams that embrace these principles often experience reduced costs, improved customer satisfaction, and a stronger foundation for growth. By adopting Lean practices, small businesses can thrive in competitive markets while delivering exceptional value to their customers.

Building a Lean Culture

Leadership’s Role in Lean Thinking

Leadership plays a pivotal role in establishing and sustaining a lean culture. Leaders set the vision for continuous improvement and guide their teams toward achieving it. They actively participate in improvement projects, demonstrating their commitment to change. By providing essential resources such as time and training, leaders empower teams to implement lean principles effectively.

Removing barriers that hinder progress is another critical responsibility. Leaders foster open communication, ensuring that employees feel heard and valued. Celebrating successes reinforces the culture of continual improvement, motivating teams to strive for excellence. For example, leaders who embrace a learning mindset view failures as opportunities for growth. This perspective encourages innovation and resilience within the organization.

Monitoring progress through key performance indicators helps leaders assess the impact of lean initiatives. Sustaining a lean culture requires ongoing dedication, with leaders continuously improving their own skills to guide their teams effectively. By embodying these practices, leaders create an environment where lean thinking thrives.

Encouraging Team Collaboration

Team collaboration is essential for the success of lean initiatives. Shared knowledge among team members enhances visibility and fosters idea sharing, which strengthens teamwork. Optimized workflows result from effective collaboration, improving productivity and individual efficiency.

Regular feedback loops keep everyone informed and engaged. Teams can proactively identify areas for improvement and work together to address them. Employees on the frontlines often provide fresh perspectives, helping to identify waste and uncover opportunities for improvement. Their active participation fosters ownership and accountability, ensuring that everyone feels invested in the outcomes.

Engaged employees bring problem-solving power to the table. They tackle challenges and propose solutions, driving meaningful change. For instance, a manufacturing team might collaborate to redesign a production process, reducing waste and improving efficiency. Encouraging collaboration not only enhances workflows but also builds a sense of unity and shared purpose within the organization.

Developing a Continuous Improvement Mindset

Developing a mindset of continuous improvement involves fostering a proactive approach to change. Employees who constantly survey their environment can better understand shifts and determine how to respond effectively. This mindset prioritizes deliberate actions that focus on activities with the greatest potential for impact.

Organizations can empower employees to contribute ideas for improvement. For example, Qorvo encouraged its teams to submit suggestions, resulting in 755 ideas that improved product quality, 216 that enhanced safety, and 893 that increased satisfaction. Employees who feel involved in the process take ownership of outcomes and become proactive problem solvers.

Embracing change as an opportunity to learn prepares organizations for unknown challenges. Teams that adopt this mindset can turn obstacles into competitive advantages. By fostering a culture of continuous improvement, organizations ensure that their systems and teams remain adaptable and resilient in the face of change.

Overcoming Resistance to Change

Resistance to change often poses a significant challenge when implementing Lean Thinking. Systems and teams may struggle to adapt due to uncertainty, fear of failure, or attachment to existing processes. Overcoming this resistance requires a strategic and inclusive approach.

Involving and empowering the people affected by the change is a critical first step. Teams that feel included in decision-making processes are more likely to embrace new methods. Leaders can encourage participation by seeking input, addressing concerns, and involving employees in planning and execution. For example, a manufacturing team might collaborate on redesigning workflows, ensuring that every member understands their role in the new system.

Clear communication of the vision and benefits of Lean Thinking is equally important. Leaders should articulate how the changes align with organizational goals and improve outcomes for both employees and customers. Sharing success stories from other systems and teams can inspire confidence and demonstrate the potential impact. For instance, a healthcare team might learn how Lean Thinking reduced patient wait times and improved care quality in similar organizations.

Implementing and sustaining change requires practical tools and consistent effort. Kaizen events, which focus on small, incremental improvements, can help teams address specific challenges. Visual management tools, such as Kanban boards, provide transparency and keep everyone aligned. These tools ensure that progress remains visible and measurable, fostering accountability and motivation.

Continuous adaptation and innovation play a vital role in overcoming resistance. Organizations must remain flexible, adjusting strategies as they evolve. Teams that embrace a mindset of learning and experimentation are better equipped to navigate challenges. For example, a software development team might refine its processes based on feedback, ensuring that improvements align with user needs.

Building a lean culture requires persistence and commitment. Leaders must model the principles of Lean Thinking, demonstrating their dedication to continuous improvement. By fostering collaboration, maintaining open communication, and leveraging practical tools, systems and teams can overcome resistance and achieve lasting success.

If your organization seeks to implement Lean Thinking and overcome resistance to change, reach out to us. Our expertise can guide your systems and teams toward creating a lean culture that drives efficiency and value.

Benefits of Lean Thinking

Boosting Efficiency and Productivity

Lean Thinking enhances efficiency and productivity by streamlining processes and eliminating unnecessary steps. Systems and teams that adopt lean principles focus on identifying value-added activities and removing waste. This approach ensures that resources are used effectively, leading to faster and more reliable outcomes.

For example, a manufacturing team might implement lean tools like value stream mapping to identify bottlenecks in production. By addressing these inefficiencies, they can reduce cycle times and increase throughput. Similarly, a healthcare system might redesign its patient admission process to minimize waiting times, ensuring smoother workflows and better service delivery. These improvements not only boost productivity but also create a more organized and responsive environment.

Teams that prioritize efficiency often experience higher morale and engagement. Employees working in streamlined systems face fewer obstacles, allowing them to focus on delivering quality results. This alignment between processes and goals fosters a culture of continuous improvement, driving long-term success.

Reducing Costs Through Waste Elimination

Eliminating waste is a core principle of lean thinking, directly contributing to cost reduction. Waste in processes, such as overproduction, defects, and excess inventory, consumes resources without adding value. By identifying and addressing these inefficiencies, systems and teams can significantly lower operational expenses.

For instance, a retail business might adopt a pull system to align inventory levels with actual customer demand. This approach minimizes overproduction and reduces storage costs. In software development, addressing defects early in the coding process prevents costly rework later. These strategies ensure that resources are allocated efficiently, avoiding unnecessary expenditures.

Lean principles also encourage the use of tools like the 5S methodology to organize workspaces. A well-organized environment reduces motion waste and improves productivity, leading to cost savings. Teams that embrace waste elimination not only reduce expenses but also enhance their ability to deliver value to customers.

Enhancing Customer Satisfaction

Lean Thinking places a strong emphasis on delivering customer value, which directly impacts satisfaction. By focusing on what customers value most, systems and teams can tailor their processes to meet expectations effectively. This customer-centric approach fosters loyalty and trust.

Several industries have demonstrated how lean principles enhance customer satisfaction. Zappos empowers employees to provide exceptional service, creating a vibrant workplace and happy customers. Southwest Airlines achieves high satisfaction by empowering its teams and streamlining operations. Starbucks uses lean thinking to improve product quality and service efficiency, resulting in increased customer loyalty.

In healthcare, organizations like the NHS have adopted lean practices to reduce waiting times and improve care quality. These changes enhance patient experiences and outcomes. By eliminating waste and optimizing workflows, systems can consistently deliver high-quality services that align with customer needs.

Teams that prioritize customer value often see measurable improvements in satisfaction and retention. Lean Thinking equips organizations with the tools to adapt to changing demands, ensuring long-term success in competitive markets.

Improving Employee Engagement

Employee engagement plays a critical role in the success of systems and teams adopting lean principles. Engaged employees contribute to a culture of continuous improvement, driving both individual and organizational growth. Lean thinking fosters engagement by creating an environment where employees feel valued and empowered to make meaningful contributions.

Several factors enhance employee engagement through lean practices:

Employees bring fresh perspectives to the table. Their insights help identify waste and uncover opportunities for improvement.

Active participation in lean initiatives encourages employees to take ownership of outcomes. This sense of accountability strengthens their connection to the organization.

Engaged employees demonstrate problem-solving power. They tackle challenges head-on and propose innovative solutions that benefit the entire system.

Lean systems also emphasize shared meaning among team members. Employees gain a clear understanding of their roles and how their efforts contribute to the organization's goals. This clarity motivates them to suggest enhancements and remain committed to their work. Additionally, reducing wasteful practices allows employees to focus on critical tasks, further boosting engagement.

Professional development remains a cornerstone of lean thinking. Continuous learning opportunities and skill training empower employees to grow both personally and professionally. For example, systems that implement regular workshops or training sessions equip their teams with the tools needed to adapt to evolving challenges. This focus on development not only enhances individual capabilities but also strengthens the overall team dynamic.

Practical applications of lean principles demonstrate their impact on engagement. A manufacturing team might involve employees in redesigning workflows to eliminate inefficiencies. This collaborative approach fosters a sense of ownership and pride in the results. Similarly, a healthcare system could engage frontline staff in mapping patient care processes, ensuring that every team member feels valued and heard.

By prioritizing employee engagement, systems and teams create a foundation for sustained improvement. Engaged employees bring energy, creativity, and dedication to their roles, driving success across the organization. For those seeking to enhance engagement through lean practices, reaching out to experts can provide valuable guidance and support.

Lean thinking provides a structured approach to improving efficiency and eliminating waste. Its core principles guide systems and teams to identify value, map processes, create flow, establish pull systems, and pursue continuous improvement. These steps ensure that every action contributes to delivering customer value while reducing inefficiencies.

Building a Lean culture requires leadership commitment, employee engagement, and a focus on problem-solving. Teams can start by recognizing waste, using tools like Value Stream Mapping, and involving frontline workers in improvement efforts. By fostering this mindset, organizations can achieve sustainable success and deliver exceptional value to their customers.

FAQ

What is Lean Thinking?

Lean Thinking is a methodology that focuses on reducing waste and improving efficiency. It emphasizes delivering value to customers by streamlining processes and fostering continuous improvement. Systems and teams use Lean principles to optimize workflows and achieve sustainable success.

How does Lean Thinking eliminate waste?

Lean Thinking identifies waste through tools like Value Stream Mapping. It categorizes waste into seven types, such as defects and overproduction. Teams analyze processes to remove non-value-added activities, ensuring resources are used effectively.

Can small businesses benefit from Lean Thinking?

Yes, small businesses can adopt Lean Thinking to streamline operations and reduce costs. Tools like the 5S methodology and pull systems help small teams improve efficiency and align production with customer demand.

What tools are commonly used in Lean Thinking?

Common tools include Value Stream Mapping, Kanban boards, and the 5S methodology. These tools help systems visualize workflows, organize workspaces, and identify inefficiencies. Teams use them to implement Lean principles effectively.

How does Lean Thinking improve customer satisfaction?

Lean Thinking focuses on delivering what customers value most. By eliminating waste and optimizing processes, systems ensure timely delivery and high-quality outcomes. This customer-centric approach fosters trust and loyalty.

What industries can apply Lean Thinking?

Lean Thinking applies to various industries, including manufacturing, healthcare, software development, and small businesses. Each sector uses Lean principles to address unique challenges and improve efficiency.

How can teams sustain a Lean culture?

Teams sustain a Lean culture by fostering continuous improvement and engaging employees. Leadership plays a key role in providing resources and celebrating successes. Regular training and feedback loops ensure ongoing progress.

Where can I learn more about Lean Thinking?

To learn more about Lean Thinking and its applications, reach out to us. Our expertise helps systems and teams implement Lean principles, eliminate waste, and achieve long-term success.