How to Identify and Fix Inefficient Business Processes

Inefficient business processes hinder growth and reduce productivity. They waste time, drain resources, and create unnecessary delays in achieving organizational goals. For example, businesses lose at least $1.3 million annually due to inefficiencies, while 70% of executives spend a significant portion of their time on repetitive tasks. These challenges increase operational costs and impact customer satisfaction.

Streamlining workflows through Business Process Management (BPM) can help organizations maximize resources. By eliminating redundancies, companies reduce costs and allow employees to focus on tasks that drive sales and innovation. Modern tools and knowledge-driven strategies are essential for effective business management, ensuring sustainable success.

Key Takeaways

Bad business processes waste time and money for companies.

Fixing workflows with BPM can save money and boost work speed.

Drawing out workflows shows problems and makes work smoother.

Listening to workers' ideas can show hidden problems and build trust.

Using machines for boring tasks lowers mistakes and saves time.

Checking processes often keeps them working well as needs change.

Using new tools and linking systems makes work faster and easier.

Using methods like Lean and Six Sigma helps businesses grow better.

Understanding Inefficient Business Processes

Key Characteristics

Wasted Time and Resources

Inefficient business processes often consume more time and resources than necessary. Tasks that should take minutes may stretch into hours due to redundant steps or outdated methods. For instance, employees might spend excessive time manually inputting data that could be automated. This not only delays project timelines but also diverts resources from more strategic initiatives. Over time, these inefficiencies can erode profitability and hinder growth.

Bottlenecks and Delays

Bottlenecks occur when a specific step in a process slows down the entire workflow. These delays often result from poor task allocation, limited resources, or dependency on a single individual or system. For example, a department waiting for approvals from a manager who is frequently unavailable can disrupt operations. Such delays frustrate employees, reduce productivity, and negatively impact customer satisfaction.

Lack of Clarity or Accountability

Processes lacking clear guidelines or accountability often lead to confusion. Employees may not understand their roles or responsibilities, resulting in duplicated efforts or missed tasks. Without defined ownership, issues may go unresolved, further compounding inefficiencies. This lack of structure can also create communication gaps, making it difficult to track progress or identify areas for improvement.

Common Causes

Outdated Systems or Tools

Legacy systems and outdated tools are common culprits behind inefficient business processes. These technologies often lack the speed and functionality required to meet modern demands. For example, manual data entry systems can slow down operations and increase the likelihood of errors. Upgrading to modern software solutions can significantly enhance efficiency by automating repetitive tasks and streamlining workflows.

Poor Communication

Ineffective communication creates silos within organizations, where departments operate independently without collaboration. This lack of coordination can lead to duplicated efforts, missed deadlines, and inconsistent outcomes. For instance, a marketing team unaware of a product update from the development team may launch campaigns with outdated information. Clear communication channels and collaboration tools can help bridge these gaps.

Redundant or Unnecessary Steps

Many business processes include steps that no longer serve a purpose. These redundant tasks waste time and resources, adding complexity without value. For example, requiring multiple approvals for routine decisions can slow down workflows. Simplifying processes by eliminating unnecessary steps can improve efficiency and allow employees to focus on more impactful activities.

Key Insight: Operational inefficiencies can have far-reaching consequences. They can harm customer satisfaction, frustrate employees, damage brand reputation, and limit scalability. Addressing these issues requires a thorough evaluation of existing processes, identification of pain points, and implementation of targeted solutions.

Identifying Inefficiencies in Business Processes

Conducting a Process Audit

Mapping Workflows

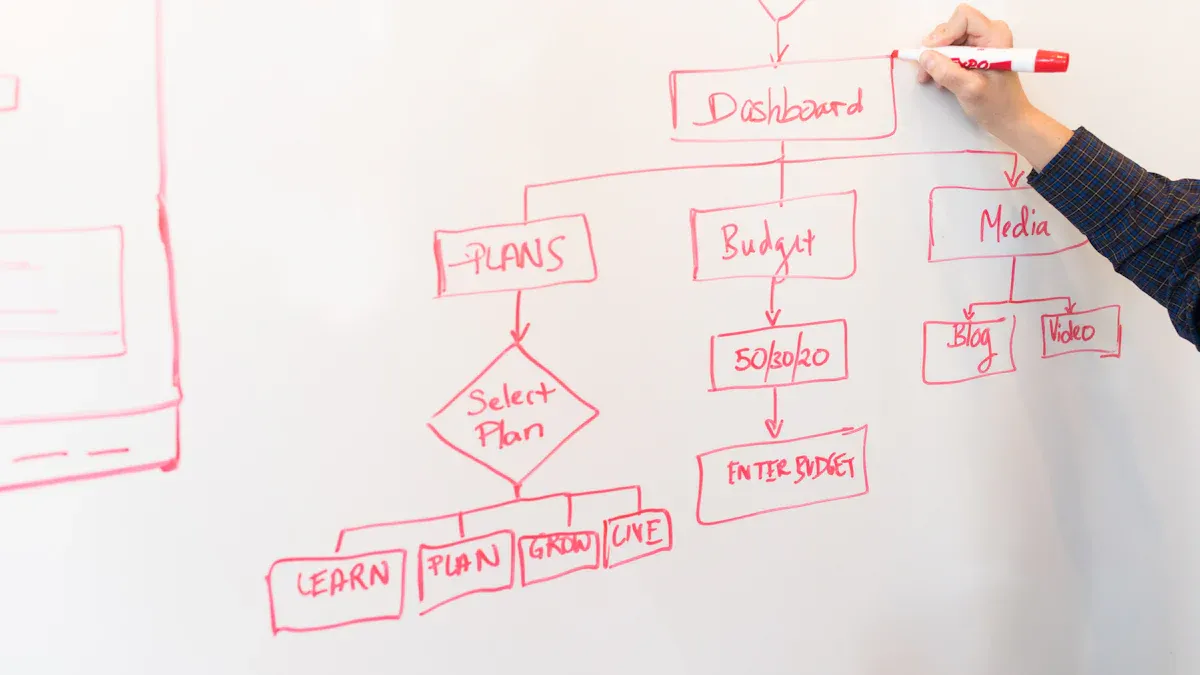

Mapping workflows is a critical first step in identifying inefficiencies. This technique allows organizations to visualize their business processes, making it easier to pinpoint redundancies and bottlenecks. For example, workflow process mapping can reveal tasks that add no value, such as repetitive approvals or manual data entry. A case study highlighted how a company improved operational efficiency by identifying and removing tasks that slowed down operations. This approach not only streamlines workflows but also enhances overall productivity.

Benefits of Workflow Mapping:

Identifies redundancies and bottlenecks.

Highlights non-value-adding tasks.

Provides a clear visual representation of processes for better analysis.

Identifying Pain Points

A process audit also involves identifying pain points that hinder efficiency. These pain points may include delays, resource constraints, or unclear responsibilities. Data analytics plays a crucial role in uncovering hidden inefficiencies. For instance, audits that incorporate data analytics can reveal improvement opportunities that might otherwise go unnoticed. Regular audits also act as an early warning system for compliance gaps, helping businesses address issues before they escalate.

Evidence Description | Impact on Business Process Inefficiencies |

|---|---|

Quality audits serve as an early warning system for regulatory compliance gaps. | Helps identify compliance issues before they escalate into larger problems. |

Data analytics in audits reveal hidden improvement opportunities. | Enables companies to discover inefficiencies they were unaware of. |

Regular audits uncover cost-saving opportunities in various operational areas. | Leads to reduced waste, streamlined workflows, and lower costs. |

Employee Feedback

Encouraging Open Communication

Employees often have firsthand knowledge of inefficiencies within their workflows. Encouraging open communication creates a platform for them to share insights and suggest improvements. Organizations that foster a culture of transparency benefit from higher employee engagement and better problem-solving. For example, employees who receive regular feedback are 3.6 times more likely to feel motivated, which can lead to more proactive identification of inefficiencies.

Using Surveys or Interviews

Surveys and interviews provide structured ways to gather employee feedback. These tools help organizations understand the challenges employees face and identify areas for improvement. For instance, feedback collected through surveys has been shown to reduce turnover rates by 14.9%, as employees feel valued and heard. By leveraging these insights, businesses can implement targeted solutions to streamline their processes.

Evidence Type | Statistic |

|---|---|

Feedback boosts retention | 14.9% decrease in turnover rates among employees who received feedback. |

Daily feedback motivates | Employees are 3.6 times more likely to feel motivated with daily feedback. |

Analyzing Performance Metrics

Tracking Time, Cost, and Output

Performance metrics provide measurable insights into the efficiency of business processes. Tracking time, cost, and output helps organizations identify areas where resources are being wasted. For example, advanced process control technologies have been used in manufacturing to optimize performance, reducing raw material usage while maintaining output quality. These metrics allow businesses to focus on areas that require immediate attention, ensuring continuous improvement.

Examples of Performance Metrics in Action:

Advanced Process Control (APC) technologies optimize resource usage.

Automated material handling systems enhance accuracy and reduce errors.

Digital twins simulate scenarios to minimize downtime and improve efficiency.

Comparing Performance to Goals

Comparing actual performance to organizational goals highlights gaps that need to be addressed. Variance analysis, for instance, compares expected outcomes to actual results, revealing inefficiencies. Statistical methods like regression modeling and anomaly detection algorithms also help identify patterns that impact efficiency. By leveraging these tools, businesses can align their processes with strategic objectives, ensuring better outcomes.

Statistical Method | Description |

|---|---|

Performance Metric Development | Translates raw audit trail data into meaningful performance metrics for scheduling efficiency. |

Statistical Process Control | Uses control charts to monitor processes and identify deviations from acceptable performance. |

Correlation Analysis | Examines relationships between scheduling variables to find dependencies affecting efficiency. |

Regression Modeling | Builds frameworks to predict future scheduling needs based on historical data. |

Variance Analysis | Compares actual outcomes against expected parameters to identify inefficiencies. |

Anomaly Detection Algorithms | Identifies unusual patterns in scheduling data that may indicate inefficiencies. |

Cluster Analysis | Groups similar scheduling patterns to uncover hidden inefficiencies. |

Fixing Inefficient Business Processes

Streamlining Workflows

Eliminating Redundant Steps

Eliminating redundant steps is a critical strategy for streamlining workflows. Redundant tasks often slow down operations and consume valuable resources without adding value. By removing these inefficiencies, businesses can achieve faster project completion and improved productivity. For instance, organizations that eliminate unnecessary approvals or duplicate data entry processes often experience measurable gains in workflow speed.

Evidence Type | Description |

|---|---|

Improvements in Workflow Speed | Businesses report measurable increases in workflow speed due to the elimination of redundant tasks. |

Labor Productivity Gains | Productivity can increase by 30-50% with integrated processes, allowing employees to focus on higher-value tasks. |

Link Between Productivity and Process Integration | Fewer interruptions and bottlenecks lead to faster project throughput and higher profitability. |

Streamlined workflows not only enhance operational efficiency but also free up employees to focus on strategic initiatives. This approach ensures that resources are allocated to activities that directly contribute to organizational goals.

Automating Repetitive Tasks

Automation is another powerful tool for improving workflow efficiency. Repetitive tasks, such as data entry or invoice processing, can be automated using modern software solutions. Automation reduces the likelihood of human error, accelerates task completion, and allows employees to concentrate on more complex responsibilities. For example, automating customer service responses through chatbots can significantly reduce response times while maintaining service quality.

Organizations that adopt automation often see a marked improvement in their overall efficiency. By leveraging technology to handle routine tasks, businesses can optimize their processes and achieve better outcomes.

Enhancing Communication

Implementing Collaboration Tools

Effective communication is essential for seamless business processes. Collaboration tools, such as project management software and instant messaging platforms, facilitate real-time communication and coordination among team members. These tools help break down silos, ensuring that departments work together toward shared objectives. For instance, using platforms like Slack or Microsoft Teams enables employees to share updates, track progress, and resolve issues quickly.

Collaboration tools also provide a centralized space for storing documents and tracking project timelines. This transparency reduces misunderstandings and ensures that everyone remains aligned with organizational goals.

Defining Roles and Responsibilities

Clear roles and responsibilities are vital for eliminating confusion and ensuring accountability. When employees understand their specific duties, they can focus on their tasks without duplicating efforts or overlooking critical steps. Defining roles also helps managers identify performance gaps and allocate resources more effectively.

For example, assigning a dedicated project manager to oversee a team ensures that tasks are completed on time and within budget. This clarity fosters a sense of ownership among employees, leading to higher engagement and better results.

Upgrading Systems and Tools

Investing in Modern Software

Outdated systems often hinder efficiency and limit scalability. Investing in modern software solutions can transform business processes by automating tasks, improving data accuracy, and enhancing user experience. Advanced tools, such as enterprise resource planning (ERP) systems, integrate various functions like finance, supply chain, and human resources into a single platform.

Performance Metric | Before Upgrade | After Upgrade | Improvement (%) |

|---|---|---|---|

First-pass yield | 90% | 98% | 8.89% |

Reduction in rework | N/A | 80% | N/A |

Employee engagement increase | N/A | N/A | N/A |

Modern software not only boosts operational efficiency but also enhances employee satisfaction. Employees equipped with intuitive tools are more likely to stay engaged and productive, reducing turnover rates and fostering a positive work environment.

Integrating Systems for Efficiency

System integration is another key aspect of upgrading tools. Disconnected systems often lead to data silos, making it difficult to access accurate information. Integrating systems ensures seamless data flow across departments, enabling better decision-making and faster response times.

For example, integrating customer relationship management (CRM) software with marketing automation tools allows businesses to track customer interactions and tailor campaigns more effectively. This integration not only improves efficiency but also enhances the customer experience, driving loyalty and retention.

Tip: Organizations that upgrade their systems and integrate tools often observe significant performance improvements. Engaged employees are 87% less likely to leave their jobs, and 70% believe that quality leadership enhances their engagement. These changes contribute to a more productive and satisfied workforce.

Tools and Techniques for Improving Business Processes

Process Mapping Tools

Examples and Benefits

Process mapping tools help organizations visualize workflows, identify inefficiencies, and streamline operations. These tools provide a clear representation of each step in a process, making it easier to spot redundancies or bottlenecks. Some of the most effective tools include:

Simple flowchart sketch: A straightforward method for visualizing basic processes.

Gitmind: Offers advanced diagrams like SIPOC and swimlanes, enabling deeper analysis of workflows.

Lucidchart: Features user-friendly templates and BPMN symbols for detailed process mapping.

ProcessMaker: An enterprise-grade tool that automates workflows and enhances efficiency.

Each tool caters to different organizational needs, from simple visualization to complex process automation. For example, Gitmind and Lucidchart are ideal for teams seeking detailed insights, while ProcessMaker suits businesses aiming to integrate automation into their workflows. By leveraging these tools, companies can improve clarity, reduce errors, and enhance overall productivity.

Tip: Choose a process mapping tool that aligns with your organization's complexity and goals to maximize its benefits.

Automation Software

Tasks Suitable for Automation

Automation software eliminates repetitive tasks, allowing employees to focus on strategic activities. Tasks such as data entry, invoice processing, and customer service responses are well-suited for automation. Automated systems operate continuously, reducing labor costs and improving resource utilization.

Automation has demonstrated measurable benefits:

Metric | Description |

|---|---|

Increased productivity | Automation can enhance productivity growth by 0.8%-1.4%, leading to significant organizational gains. |

Reduced operational costs | Automating administrative tasks cuts labor costs and processing time, resulting in savings. |

Improved decision-making | Automation tools provide quick data processing, enabling strategic decisions that drive growth. |

Reduced employee burnout | Automation allows employees to focus on meaningful tasks, increasing job satisfaction and reducing burnout. |

Additionally, automation minimizes human errors, enhances efficiency, and boosts employee satisfaction by reducing monotonous work. For instance, chatbots in customer service can handle routine inquiries, freeing up human agents for complex issues. Businesses that adopt automation often experience faster workflows and higher accuracy.

Note: Automating repetitive tasks not only saves time but also fosters a more engaged and motivated workforce.

Continuous Improvement Frameworks

Lean and Six Sigma Methodologies

Continuous improvement frameworks like Lean and Six Sigma provide structured approaches to enhance business processes. Lean focuses on eliminating waste and maximizing value, while Six Sigma emphasizes reducing variability and improving quality.

Lean principles encourage organizations to identify non-value-adding activities and streamline workflows. For example, a manufacturing company might use Lean to reduce excess inventory and improve production speed. On the other hand, Six Sigma employs data-driven techniques to minimize defects and ensure consistent outcomes. Tools like DMAIC (Define, Measure, Analyze, Improve, Control) guide teams through systematic problem-solving.

By combining Lean and Six Sigma, businesses can achieve both efficiency and quality. These methodologies foster a culture of continuous improvement, ensuring long-term success and adaptability in a competitive market.

Callout: Organizations that embrace Lean and Six Sigma often report higher customer satisfaction and lower operational costs, making these frameworks invaluable for process optimization.

Measuring the Success of Process Improvements

Evaluating Post-Implementation Metrics

Comparing Before-and-After Data

Measuring the success of process improvements begins with comparing performance data from before and after implementation. This approach provides a clear picture of the impact on efficiency, quality, and cost. For example, a fast-food chain automated its order posting process, saving four seconds per order. Across all registers, this change resulted in four hours saved daily, demonstrating the tangible benefits of automation. Similarly, an IT department reduced service desk tickets related to Outlook by offering targeted training, which improved employee productivity.

Organizations across industries rely on specific metrics to evaluate success. These include:

IT and Software Development: Metrics such as user adoption rates, system stability, and mean time between failures (MTBF).

Construction: Indicators like safety performance, budget variance, and material defect rates.

Marketing: A combination of ROI, brand sentiment analysis, and customer engagement metrics.

Research and Development: Balanced scorecards to measure immediate outcomes and long-term potential.

Non-Profit: Metrics focusing on beneficiary reach and community engagement levels.

A structured approach to post-implementation metrics ensures that improvements align with organizational goals. The table below highlights some of the most reliable metrics used across industries:

Metric Type | Description |

|---|---|

ROI | Measures the financial impact of improvements by comparing costs to revenue increases or expense reductions. |

Product Quality | Assesses improvements through defect counts, product returns, and customer complaints. |

Evaluates efficiency gains by measuring output increases without additional time investment. |

By tracking these metrics, businesses can quantify the success of their process changes and identify areas for further refinement.

Gathering Feedback

Employee and Customer Insights

Feedback from employees and customers provides valuable insights into the effectiveness of process improvements. Employees, as the primary users of workflows, can identify whether changes have simplified their tasks or introduced new challenges. Companies that involve employees in improvement initiatives often see a 14% increase in productivity and a 19% boost in satisfaction. Engaged employees are more likely to embrace changes and contribute to ongoing optimization efforts.

Customer feedback is equally important. It reveals how process changes impact service quality and satisfaction. For instance, fewer complaints or faster response times indicate that improvements are meeting customer expectations. Surveys, interviews, and focus groups are effective tools for gathering this information.

When collecting feedback, organizations should ensure that metrics meet the following criteria:

Criteria | Description |

|---|---|

Relevance and specificity | Indicators must be directly linked to the processes you want to optimize. |

Data reliability | Indicators must be based on objective, verifiable information to guarantee accurate measurement. |

Ability to act | Indicators must enable rapid and effective action in the event of deviations. |

Adaptability to change | Indicators must be regularly reassessed to ensure they remain aligned with current objectives. |

Simplicity | Indicators must be easy to understand for all stakeholders, ensuring smooth daily use. |

By combining quantitative metrics with qualitative feedback, businesses can gain a comprehensive understanding of their process improvements. This dual approach ensures that both operational efficiency and stakeholder satisfaction are addressed effectively.

Building a Culture of Continuous Improvement

Encouraging Innovation

Rewarding Creative Solutions

Organizations thrive when employees feel empowered to think creatively. Encouraging innovation involves creating an environment where individuals can propose new ideas without fear of criticism. Recognizing and rewarding these efforts motivates employees to contribute actively to process improvements. For example, companies that implement structured reward systems often see higher engagement levels and more innovative solutions.

Case studies highlight the tangible benefits of fostering innovation. One study showed a 25% reduction in process cycle time after implementing employee-driven ideas. Another reported a 20% increase in product yield and steady improvements in customer satisfaction metrics. These results demonstrate the value of rewarding creativity in driving measurable outcomes.

Case Study | Improvement Type | Numerical Evidence |

|---|---|---|

Case Study 3 | Process Cycle Time | Reduction by nearly 25% |

Case Study 4 | Product Yield | Increase by 20% |

Quality Metrics | Steady improvements in customer satisfaction indices |

Tip: Publicly acknowledging innovative contributions can inspire others to think outside the box, fostering a culture of continuous improvement.

Regular Process Reviews

Scheduling Audits

Regular audits ensure that business processes remain efficient and aligned with organizational goals. Scheduling these reviews at consistent intervals allows teams to identify inefficiencies before they escalate. For instance, quarterly audits can uncover bottlenecks or outdated practices that hinder productivity. These reviews also provide an opportunity to evaluate the effectiveness of recent process changes.

Organizations benefit from using structured frameworks during audits. Tools like checklists and performance dashboards help teams focus on critical areas. By maintaining a routine schedule, businesses can stay proactive in addressing inefficiencies and adapting to evolving needs.

Adapting to Change

Adaptability is essential for sustaining long-term success. Market conditions, customer expectations, and technological advancements constantly evolve. Businesses must adjust their processes to remain competitive. For example, companies that embrace digital transformation often outperform those that resist change. Updating workflows, integrating new tools, and training employees on emerging technologies ensure that processes stay relevant.

A culture of adaptability requires leadership support. Managers should encourage teams to view change as an opportunity rather than a challenge. Providing resources and training helps employees transition smoothly, minimizing resistance. Over time, this mindset fosters resilience and positions the organization for sustained growth.

Callout: Regular reviews and a willingness to adapt ensure that processes remain efficient, even in dynamic environments.

Identifying and fixing inefficient business processes is essential for improving productivity, reducing costs, and fostering employee satisfaction. Inefficiencies, such as workplace stress and wasted time, cost companies billions annually.

Statistic | Impact on Business |

|---|---|

Companies lose $500 billion annually because of workplace stress and confusion | Significant financial loss due to inefficiencies |

40% of workers report lost productivity due to multitasking | Decreased overall productivity |

Employees waste, on average, over 2 hours a day on non-work activities | Loss of valuable work hours |

Organizations can address these challenges by understanding inefficiencies, implementing targeted solutions, and measuring results. Taking immediate steps, such as conducting a process audit or adopting modern tools, ensures long-term success.

Tip: Start small but act now. Even minor improvements can lead to significant gains over time.

FAQ

What are the first steps to identify inefficiencies in a business process?

Start by conducting a process audit. Map workflows to visualize each step and identify bottlenecks or redundancies. Encourage employee feedback through surveys or interviews to uncover hidden pain points. Use performance metrics to track time, cost, and output for a data-driven approach.

How can automation improve business processes?

Automation eliminates repetitive tasks like data entry or invoice processing. It reduces human error, speeds up workflows, and allows employees to focus on strategic activities. Tools like chatbots or robotic process automation (RPA) enhance efficiency and improve resource utilization.

What tools are best for mapping workflows?

Popular tools include Lucidchart, Gitmind, and ProcessMaker. These tools provide visual representations of workflows, helping businesses identify inefficiencies. For simple processes, flowchart sketches work well. For complex workflows, enterprise-grade tools like ProcessMaker offer automation features.

How often should businesses review their processes?

Regular reviews, such as quarterly or biannual audits, are ideal. Frequent evaluations help identify inefficiencies early and ensure processes stay aligned with organizational goals. Adapting to changes in market conditions or technology also requires periodic assessments.

What are the benefits of integrating systems?

System integration eliminates data silos and ensures seamless information flow across departments. It improves decision-making, reduces duplication, and enhances efficiency. For example, integrating CRM software with marketing tools enables better customer tracking and personalized campaigns.

How can employee feedback improve processes?

Employees often have firsthand knowledge of inefficiencies. Gathering their feedback through surveys or interviews provides actionable insights. Open communication fosters engagement and helps identify practical solutions for streamlining workflows.

What is the role of Lean and Six Sigma in process improvement?

Lean focuses on eliminating waste, while Six Sigma reduces variability and defects. Together, they provide a structured framework for continuous improvement. Businesses using these methodologies often achieve higher efficiency, better quality, and lower operational costs.

How can businesses measure the success of process improvements?

Compare performance metrics before and after implementation. Track time savings, cost reductions, and quality improvements. Gather feedback from employees and customers to assess satisfaction levels. Use tools like ROI analysis and variance tracking for measurable results.

Tip: Regularly update metrics to ensure they align with evolving business goals.