The Ultimate Guide to Optimizing Business Processes for Better Results

Businesses thrive when their operations run efficiently. Optimization of business processes serves as a critical methodology to achieve this goal. It identifies inefficiencies, streamlines workflows, and maximizes the use of available resources. For instance, manufacturing companies often report productivity increases of up to 35% within the first year of process optimization, while operational costs drop by 25-30%. Retailers reduce inventory costs by 20-25%, improving product availability and customer satisfaction. These results highlight how improved systems not only cut costs but also enhance overall performance, driving sustainable growth.

Key Takeaways

Improving how businesses work saves time, money, and effort.

Make customers happy by fixing workflows to avoid mistakes.

Involve all workers to create a habit of better ideas.

Use facts and data to find problems and make fixes.

Set clear goals using SMART to check progress and stay on track.

Use tools and machines to make work easier and faster.

Check and change processes often to keep up with trends.

Real examples show how better processes help many businesses succeed.

What Is Optimization of Business Processes?

Definition and Core Principles

Optimization of business processes refers to the practice of improving workflows, systems, and operations to achieve greater efficiency and effectiveness. It involves implementing strategies and methods to identify and resolve inefficiencies, ensuring smoother operations and adaptability in competitive markets. By continuously evaluating and improving processes, businesses can enhance quality and reduce risks associated with failures.

Core principles of business process optimization include:

Customer focus: Prioritizing customer needs and satisfaction.

Total employee involvement: Engaging employees at all levels to contribute to improvements.

Process-centered approach: Focusing on workflows rather than isolated tasks.

Continual improvement: Regularly refining processes to maintain efficiency.

Fact-based decision-making: Using data and insights to guide changes.

These principles establish a foundation for businesses to streamline operations and remain competitive.

Key Components of Business Process Optimization

Effective optimization of business processes relies on several key components:

Feedback loops: Mechanisms to monitor and control processes.

Process mapping: Visualizing workflows to identify bottlenecks and inefficiencies.

Automation and technology: Leveraging tools to streamline repetitive tasks and improve accuracy.

Cost reduction: Eliminating unnecessary expenses through efficient workflows.

Risk mitigation: Proactively addressing potential challenges to avoid disruptions.

For example, methodologies like Lean Six Sigma focus on eliminating waste and improving quality, while Business Process Reengineering (BPR) involves a complete redesign of workflows. These approaches, combined with continuous monitoring, ensure sustained improvements.

Examples of Processes That Benefit from Optimization

Many business processes have shown significant improvements through optimization. Below are some examples:

Business Process | Description | Time Savings |

|---|---|---|

Work Order Management | Automation of work orders at a busy airport reduced processing time from 30 hours to 20 minutes per week. | 29 hours 40 minutes per week |

Procurement Automation | An automated procurement platform cut the payment process from 100 days to significantly less, saving over 160 hours. | 160 hours |

These examples demonstrate how optimizing processes can lead to substantial time savings and improved operational efficiency. By adopting strategies like automation and process standardization, businesses can achieve measurable results.

Why Is Optimization of Business Processes Important?

The Cost of Inefficiency in Business Operations

Inefficiencies in business operations can have far-reaching consequences. They often lead to increased costs, reduced customer satisfaction, and lower employee morale. For example, operational inefficiencies may cause delays in product delivery or errors in service execution, which can frustrate customers and harm a company's reputation. Financial analyses reveal that inefficiencies directly impact profitability by increasing expenses and limiting scalability.

Impact Type | Description |

|---|---|

Increased Costs | Operational inefficiencies lead to higher expenses, directly affecting profitability. |

Reduced Customer Satisfaction | Flawed processes can cause delays or errors, negatively impacting customer experience. |

Lower Employee Morale | Systemic issues in the workplace can frustrate staff, leading to decreased productivity. |

Negative Brand Reputation | Inefficient operations can result in poor product quality, harming brand perception. |

Scalability Issues | Inefficient procedures hinder growth and adaptation to market changes. |

Current research highlights that optimizing business processes is critical for overcoming these inefficiencies. By removing unnecessary steps and addressing performance roadblocks, businesses can reduce costs, improve financial resilience, and maximize revenue potential. This approach also fosters better employee morale and enhances customer satisfaction, creating a positive cycle of growth and improvement.

How Optimization Enhances Competitiveness

In a competitive market, businesses must continuously adapt to stay ahead. Optimization of business processes plays a vital role in enhancing competitiveness by improving operational efficiency and unlocking opportunities for growth. Industry reports show that companies leveraging optimization strategies often achieve better returns on investment and gain a stronger market position.

Evidence Type | Description |

|---|---|

KPIs | Key performance indicators help assess market position and identify improvement areas. |

ROI Benchmarking | Assesses capital utilization efficiency for better investment returns. |

Data Analysis | Identifies patterns and trends for informed decision-making. |

By analyzing data and benchmarking performance, businesses can identify areas for improvement and make informed decisions. This not only positions them as industry leaders but also ensures they remain agile in responding to market changes. Companies that prioritize optimization often experience enhanced productivity, faster time-to-market, and increased customer loyalty.

The Role of Customer Satisfaction in Process Optimization

Customer satisfaction is a cornerstone of successful business operations. Optimizing processes directly impacts customer experiences by reducing errors, improving service quality, and ensuring timely delivery. Statistical evidence underscores the importance of customer satisfaction in reinforcing the benefits of process optimization. For every 1% increase in customer satisfaction, retention rates improve by 5%. Additionally, increasing customer loyalty by just 5% can boost profits by 25-95%.

Acquiring a new customer costs five times more than retaining an existing one. This highlights the financial advantage of focusing on customer satisfaction through optimized processes.

Satisfied customers are more likely to remain loyal and recommend a business to others, creating a ripple effect that enhances brand reputation and drives growth. By prioritizing customer needs and streamlining workflows, businesses can build lasting relationships and achieve long-term success.

Steps to Achieve Optimization of Business Processes

Identifying and Mapping Current Processes

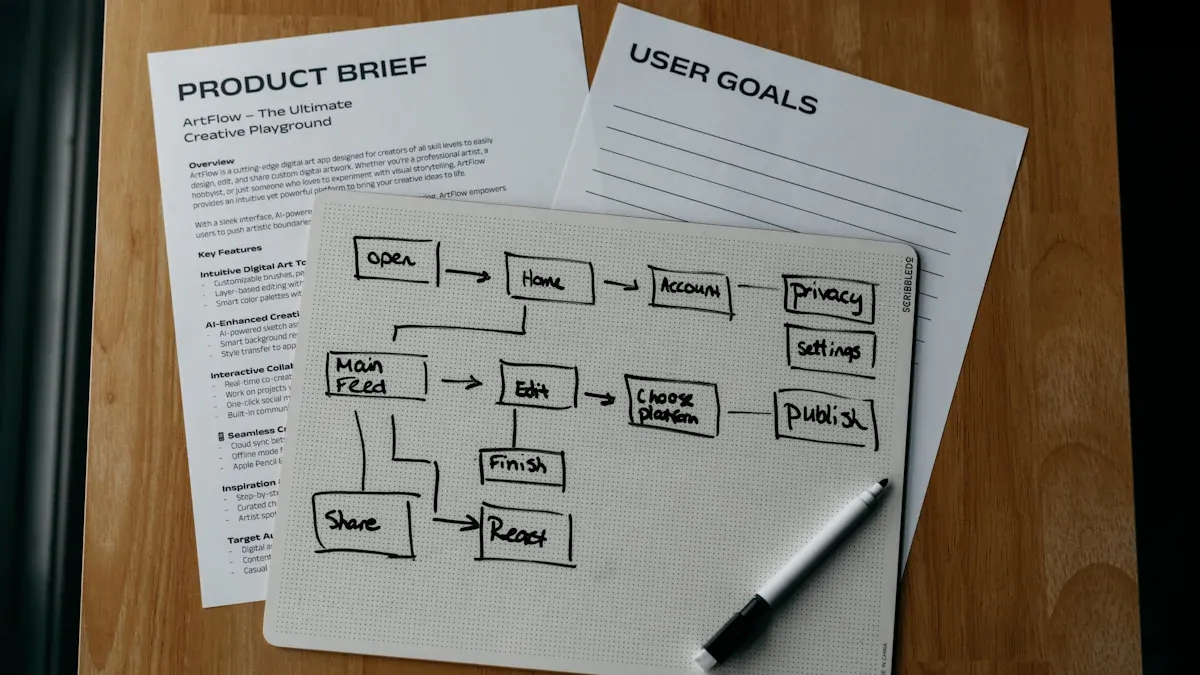

The first step in optimizing business processes involves identifying and mapping existing workflows. This stage provides a clear understanding of how tasks are performed and highlights areas that require improvement. Teams can use various tools and techniques to achieve this, such as workflow techniques, data flow diagrams, and SIPOC diagrams. These tools help visualize processes, making it easier to pinpoint inefficiencies.

For example, SIPOC diagrams focus on Suppliers, Inputs, Processes, Outputs, and Customers, offering a high-level overview of workflows. Similarly, Business Process Model and Notation (BPMN) uses standardized symbols to create graphical representations of processes, ensuring stakeholders can easily understand them. By documenting workflows, businesses can establish a foundation for further analysis and improvement.

Technique/Tool | Description |

|---|---|

Workflow techniques | A sequence of steps followed to complete a task or achieve an objective, useful for mapping complex processes. |

Data flow diagrams | Illustrate how data moves through a process, highlighting sources, destinations, and paths. |

Business process model and notation (BPMN) | Guidelines for creating graphical representations of processes, using symbols understandable by stakeholders. |

Unified model language (UML) diagrams | Visualizes the design of a system, commonly used in software engineering. |

SIPOC diagrams | Maps out a high-level overview of processes, focusing on Suppliers, Inputs, Processes, Outputs, and Customers. |

Analyzing Inefficiencies and Bottlenecks

Once processes are mapped, the next step is to analyze inefficiencies and bottlenecks. This involves identifying areas where delays, errors, or resource wastage occur. Quantitative data plays a crucial role in this analysis. For instance, key performance indicators (KPIs) can measure task completion rates, quality of work, and adherence to deadlines. Workflow mapping further helps visualize each step in a process, making it easier to spot delays.

Teams can also collect data on the time spent at each stage of a workflow. This information reveals patterns and highlights areas that need attention. By addressing these inefficiencies, businesses can streamline operations and improve overall performance.

Key methods for analysis:

Measuring KPIs to evaluate task efficiency and quality.

Mapping workflows to identify delays and redundancies.

Collecting data on time spent at each stage to uncover bottlenecks.

Setting Clear Goals for Optimization

Setting clear and measurable goals is essential for successful optimization of business processes. Goals should follow the SMART framework—specific, measurable, achievable, relevant, and time-bound. This ensures clarity and allows teams to track progress effectively. For example, a business might aim to reduce order processing time by 20% within six months.

Aligning optimization goals with overall business objectives is equally important. This alignment ensures that process improvements contribute to the organization's success. Metrics such as customer feedback, resolution times, and return rates can help measure progress. Additionally, using models like the Balanced Scorecard provides a comprehensive view of performance.

Set SMART goals to ensure clarity and assessability.

Align goals with broader business objectives for maximum impact.

Use relevant metrics, such as customer feedback and resolution times, to track progress.

Combine metrics with process documentation for actionable insights.

Focus on leading indicators to anticipate and address potential issues.

By setting clear goals, businesses can create a roadmap for optimization and ensure that improvements deliver tangible results.

Redesigning Processes for Maximum Efficiency

Redesigning processes involves rethinking workflows to eliminate inefficiencies and achieve optimal performance. Businesses often adopt innovative methods to streamline operations and enhance productivity. Successful redesigns focus on simplifying complex tasks, automating repetitive activities, and aligning processes with organizational goals.

Several companies have achieved remarkable results through process redesign:

Amazon reduced order processing time by over 60% in 2009 by redesigning its fulfillment process.

Starbucks launched an online ordering system in 2011, significantly cutting order processing times.

A hospital revamped its admissions process, reducing patient wait times from three hours to one hour.

These examples demonstrate how redesigning processes can lead to measurable improvements in efficiency and customer experience. Businesses should evaluate their workflows regularly and implement changes that address bottlenecks and redundancies.

Implementing Changes and Monitoring Results

Implementing changes requires careful planning and execution to ensure success. Businesses must communicate the purpose of changes to employees and provide training to facilitate smooth transitions. Monitoring results is equally important, as it helps measure the effectiveness of new processes and identify areas for further improvement.

Research highlights several strategies for sustaining process improvements:

Adaptation and funding play a crucial role in maintaining changes over time.

Systematic reviews emphasize the importance of clear definitions and frameworks for sustainment.

Barriers such as limited resources and funding must be addressed to ensure long-term success.

Organizations can use performance metrics, such as task completion rates and customer feedback, to track progress. Regular reviews of these metrics enable businesses to refine their processes and achieve sustainable improvements.

Tip: Use dashboards and analytics tools to visualize performance data and make informed decisions.

Embracing Continuous Improvement Practices

Continuous improvement involves regularly evaluating and enhancing processes to maintain efficiency. This approach fosters a culture of innovation and adaptability, ensuring businesses remain competitive in dynamic markets. Teams should focus on incremental changes that deliver consistent value over time.

Key practices for continuous improvement include:

Encouraging employee feedback to identify potential improvements.

Conducting regular process audits to uncover inefficiencies.

Leveraging technology to automate tasks and enhance accuracy.

For example, a software development company reduced project timelines by 40% by adopting agile methodologies. Similarly, a bank automated its loan processing system, cutting processing times by 80%. These success stories highlight the importance of embracing continuous improvement to achieve long-term success.

Benefits of Optimization of Business Processes

Improved Efficiency and Productivity

Optimization of Business Processes significantly enhances efficiency and productivity by streamlining workflows and eliminating redundancies. Businesses can achieve this by automating repetitive tasks, analyzing performance data, and aligning processes with organizational goals. For example, empirical process control uses statistical methods to monitor production quality, reducing deviations and improving efficiency. Similarly, agile methods like Scrum and Kanban enable teams to adapt quickly to changes, increasing flexibility and output.

Method/Area of Application | Description | Impact on Efficiency and Productivity |

|---|---|---|

Empirical Process Control | Uses statistical methods to analyze production data and control quality deviations. | Improves product quality and process efficiency. |

Agile Methods (e.g., Scrum, Kanban) | Focus on continuous review and adaptation of processes. | Increases team efficiency and flexibility in response to changes. |

Manufacturing Industry | Applies Statistical Process Control (SPC) to optimize production. | Enhances product quality and process efficiency. |

Project Management | Utilizes lessons learned and KPI reviews for project success. | Increases project team efficiency and success rates. |

By implementing these strategies, businesses can reduce waste, improve task completion rates, and achieve measurable productivity gains.

Cost Reduction and Resource Optimization

Optimizing business processes directly impacts cost reduction and resource utilization. Streamlined workflows eliminate unnecessary steps, reducing operational expenses. Automation further minimizes manual errors, saving time and resources. For instance, manufacturing companies report a 25-30% reduction in operational costs within the first year of adopting optimized workflows. Financial services have also improved transaction processing speeds by 60%, leading to significant cost savings.

Benefit | Description |

|---|---|

Reduced costs | Eliminates unnecessary steps and automates tasks to lower costs and boost profitability. |

Improved resource allocation | Ensures optimal use of resources, reducing waste and maximizing output. |

Competitive advantage | Provides better adaptability to market changes and customer demands. |

These improvements not only enhance profitability but also allow businesses to reinvest savings into growth initiatives.

Enhanced Employee and Customer Experiences

Process optimization benefits employees and customers alike. Employees experience increased job satisfaction when repetitive tasks are automated, allowing them to focus on high-value activities. Customers benefit from faster service delivery and improved quality. For example, healthcare facilities have reduced patient wait times by up to 40%, while manufacturing companies report a 30% improvement in customer satisfaction.

Improvement Type | Percentage Improvement |

|---|---|

Reduction in operational costs | 25-30% |

Increase in productivity | Up to 35% |

Reduction in errors and defects | 50% |

Improvement in customer satisfaction | 30% |

Increase in service delivery speed | 45-55% |

Satisfied employees contribute to better customer experiences, creating a positive feedback loop that drives long-term success.

Real-World Success Stories of Process Optimization

Real-world examples highlight the transformative impact of process optimization across industries. These success stories demonstrate how businesses have achieved remarkable results by streamlining workflows, adopting innovative strategies, and leveraging technology.

A Global Retailer’s Inventory Management Overhaul

A leading global retailer faced challenges with inventory management, including overstocking and stockouts. By implementing an advanced inventory optimization system, the company reduced excess stock by 20% and improved product availability by 30%. This change not only cut costs but also enhanced customer satisfaction by ensuring popular items were always in stock.Healthcare Facility Reduces Patient Wait Times

A busy urban hospital struggled with long patient wait times, which negatively impacted patient satisfaction. The hospital redesigned its admissions process using Lean principles. By eliminating redundant steps and automating data entry, the facility reduced average wait times from three hours to one hour. This improvement led to a 40% increase in patient satisfaction scores.Manufacturing Company Boosts Productivity

A manufacturing firm adopted Six Sigma methodologies to address production inefficiencies. By analyzing data and identifying bottlenecks, the company streamlined its assembly line processes. As a result, production output increased by 25%, and defect rates dropped by 50%. These changes significantly improved product quality and reduced operational costs.

Tip: Businesses can achieve similar results by focusing on data-driven decision-making and continuous feedback.

Technology Firm Aligns Employee Performance with Goals

A technology company implemented an advanced performance appraisal system to align employee objectives with strategic goals. The system included continuous feedback and performance analytics. This approach improved employee engagement by 35% and ensured that individual contributions supported the company’s long-term vision.Financial Institution Enhances Customer Experience

A financial institution faced delays in loan processing, frustrating customers. By automating the loan approval process, the bank reduced processing times by 60%. Customers received faster service, leading to a 30% increase in satisfaction and a 20% boost in customer retention rates.

These examples illustrate the tangible benefits of process optimization. Organizations across industries have successfully enhanced efficiency, reduced costs, and improved customer and employee experiences. By adopting similar strategies, businesses can unlock their full potential and achieve sustainable growth.

Overcoming Challenges in Process Optimization

Addressing Resistance to Change

Resistance to change is one of the most common challenges businesses face during the optimization of business processes. Employees often feel uncertain about how changes will impact their roles. Fear of job loss, insecurity about adapting to new technologies, and mistrust in leadership can amplify this resistance. Additionally, organizations with risk-averse cultures or a history of negative experiences with change may struggle to gain employee buy-in.

To address these issues, businesses should focus on clear communication and inclusion. Leaders must explain the reasons for change and how it benefits both the organization and its employees. Providing training and support can help alleviate fears about new responsibilities or technologies. Involving employees in decision-making fosters a sense of ownership and reduces resistance. For example, companies that actively listen to employee concerns and incorporate their feedback often experience smoother transitions.

Tip: Building trust through transparency and consistent actions can significantly reduce resistance to change.

Managing Costs and Resource Allocation

Optimizing business processes often requires financial investment, which can strain budgets if not managed carefully. Businesses must balance the costs of redesigning workflows, implementing new technologies, and training employees with the expected benefits. Poor resource allocation can lead to inefficiencies and missed opportunities.

To overcome this challenge, organizations can adopt financial models like activity-based budgeting, which links spending directly to outcomes. Performance-based budgeting is another effective approach, tying funding to specific metrics to ensure alignment with strategic goals. For instance, a fintech company successfully used machine learning to forecast costs and optimize resource allocation. Logistics providers have also developed detailed cost structures and revenue models to enhance operational efficiency.

Continuous monitoring of budgets and resource usage is essential for maintaining financial health. Tools like break-even analysis and scenario planning can help businesses prepare for various situations, ensuring they remain adaptable and resilient.

Securing Stakeholder Support and Collaboration

Stakeholder support is crucial for the success of any process optimization initiative. Without it, projects may face delays, conflicts, or even failure. Challenges often arise when stakeholders feel excluded from decision-making or lack trust in the project’s leadership. Misaligned goals and poor communication can further hinder collaboration.

To secure stakeholder support, businesses should prioritize transparent communication. Regular updates on project progress, challenges, and successes help build trust. Active listening and empathy demonstrate genuine care for stakeholder concerns. Collaborative problem-solving encourages stakeholders to contribute ideas and solutions, fostering a sense of partnership.

Successful projects often involve stakeholders from the beginning, ensuring their needs align with project goals. For example, closer collaboration can uncover potential risks early and address grievances promptly. This approach not only accelerates progress but also strengthens relationships, creating a foundation for long-term success.

Callout: Consistently delivering on commitments builds credibility and encourages stakeholders to remain engaged throughout the process.

Leveraging Technology for Seamless Optimization

Technology plays a pivotal role in optimizing business processes. It enables organizations to streamline workflows, reduce manual errors, and improve decision-making. By leveraging advanced tools and innovations, businesses can achieve seamless operations and maintain a competitive edge.

Key Technological Tools for Optimization

Modern tools simplify process optimization by automating repetitive tasks and providing real-time insights. Below is a table highlighting some of the most effective tools for achieving seamless optimization:

Tool | Key Features |

|---|---|

UiPath Studio | Drag-and-drop visual modeler for process modeling and workflow automation. |

UiPath Robot | Digital AI agent for control and governance tasks. |

UiPath Orchestrator | Console for tracking application configuration and performance monitoring. |

UiPath Process Mining | Accesses process monitoring information to ensure optimal operations. |

Bonitasoft | Performance reporting for real-time insights and collaboration between business and IT teams. |

Webmethods BPMS | Dynamic business rules management and real-time business activity monitoring for proactive decision-making. |

These tools empower businesses to automate complex workflows, monitor performance, and make data-driven decisions. For example, UiPath Process Mining provides actionable insights by analyzing process data, while Bonitasoft fosters collaboration between IT and business teams.

Benefits of Technology in Process Optimization

Technological advancements offer several benefits that enhance business process optimization:

AI-enabled low-code application generation: Simplifies the development of custom applications, reducing dependency on IT teams.

Enhanced performance monitoring and analytics: Provides detailed insights into operational efficiency, enabling businesses to identify and address bottlenecks.

Real-time insights for decision-making: Facilitates proactive responses to challenges, ensuring smoother operations.

For instance, Webmethods BPMS uses dynamic business rules to adapt processes in real time, helping organizations stay agile in changing environments.

Tip: Businesses should prioritize tools that integrate seamlessly with existing systems to maximize efficiency and minimize disruption.

Real-World Applications

Organizations across industries have successfully implemented technology to optimize processes. A logistics company, for example, used AI-powered tools to automate route planning, reducing delivery times by 25%. Similarly, a financial institution adopted performance monitoring software to improve loan processing speeds, enhancing customer satisfaction by 30%.

By embracing technology, businesses can unlock new levels of efficiency and productivity. These tools not only streamline operations but also provide the flexibility needed to adapt to evolving market demands.

Best Practices for Sustained Optimization of Business Processes

Fostering a Culture of Continuous Improvement

A culture of continuous improvement ensures that businesses remain adaptable and competitive. This approach encourages employees to identify inefficiencies and propose solutions regularly. Historical methodologies like Kaizen and Total Quality Management (TQM) have demonstrated the value of gradual, ongoing improvements. For example, Kaizen, integrated into the Toyota Production System, emphasizes small, consistent changes that collectively lead to significant advancements. Similarly, TQM highlights the importance of customer-centricity and employee involvement in maintaining quality.

Historical Development | Description |

|---|---|

Scientific Management | Focused on efficiency through time and motion analysis, initiated by Frederick Winslow Taylor in the 1880s and 1890s. |

Kaizen | Emphasizes gradual, ongoing improvement, integrated into the Toyota Production System post-World War II. |

Total Quality Management (TQM) | Popularized by W. Edwards Deming, highlighting customer-centricity and employee engagement in quality control. |

To foster this culture, businesses should align their processes with strategic goals and involve stakeholders at every level. Proven methodologies like Lean and Six Sigma can guide teams in identifying waste and improving workflows. Regular performance monitoring ensures that issues are addressed promptly, maintaining momentum for continuous improvement.

Tip: Recognize and reward employees who contribute to process enhancements. This motivates teams and reinforces a culture of innovation.

Training and Empowering Employees

Employees play a pivotal role in the success of process optimization. Providing them with the right tools, training, and opportunities ensures they can contribute effectively. Growth opportunities, such as skill development programs and promotions, enhance job satisfaction and engagement. Encouraging initiative fosters innovation, while access to essential resources boosts productivity.

Key strategies for empowering employees:

Offer training programs to help employees adapt to new processes and technologies.

Promote open communication to encourage collaboration and idea-sharing.

Recognize team achievements to build morale and drive success.

Provide clear pathways for career growth to retain top talent.

For example, a company that implemented ongoing training sessions saw a 20% increase in employee efficiency within six months. Empowered employees not only perform better but also contribute to a positive work environment, which directly impacts customer satisfaction.

Callout: Empowerment is not just about tools and training. It’s about creating an environment where employees feel valued and trusted.

Regularly Reviewing and Updating Processes

Regular reviews ensure that processes remain relevant and effective. Businesses should adopt methodologies like Agile, Lean, and Six Sigma to refine workflows continuously. Tools such as process mapping and value stream mapping (VSM) help visualize inefficiencies and identify areas for improvement.

Popular methodologies for process refinement:

Agile methodology for iterative improvements.

Lean manufacturing to eliminate waste.

PDCA (Plan-Do-Check-Act) model for structured problem-solving.

SIPOC analysis to understand process inputs and outputs.

For instance, a manufacturing company using the PDCA model reduced production defects by 30% within a year. Regular updates also help businesses adapt to market changes, ensuring they maintain a competitive edge. By integrating feedback from employees and customers, organizations can make informed decisions that drive long-term success.

Note: Schedule periodic process audits to identify inefficiencies before they escalate into larger issues.

Using Metrics and KPIs to Track Progress

Tracking progress is essential for ensuring the success of business process optimization. Metrics and Key Performance Indicators (KPIs) provide measurable data that helps organizations evaluate their performance and identify areas for improvement. By focusing on specific metrics, businesses can make informed decisions and align their processes with strategic goals.

What Are Metrics and KPIs?

Metrics are quantifiable measures used to assess the performance of a specific process or activity. KPIs, on the other hand, are a subset of metrics that focus on critical areas directly tied to organizational objectives. For example, while a metric might measure the number of customer inquiries resolved, a KPI could track the percentage of inquiries resolved within 24 hours.

Tip: KPIs should be actionable and aligned with business goals to ensure they drive meaningful improvements.

Types of Metrics and KPIs

Businesses can use various types of metrics and KPIs depending on their industry and objectives. Below are some common categories:

Operational Metrics: Measure efficiency and productivity, such as cycle time or error rates.

Financial KPIs: Focus on profitability and cost management, such as revenue growth or return on investment (ROI).

Customer Satisfaction Metrics: Assess customer experience, including Net Promoter Score (NPS) or customer retention rates.

Employee Performance KPIs: Evaluate workforce effectiveness, such as task completion rates or training participation.

Metric/KPI Type | Example | Purpose |

|---|---|---|

Operational Metrics | Cycle time | Improve process efficiency |

Financial KPIs | Revenue growth | Track profitability |

Customer Satisfaction | Net Promoter Score (NPS) | Measure customer loyalty |

Employee Performance | Training participation rate | Enhance workforce skills |

How to Use Metrics and KPIs Effectively

To maximize the benefits of metrics and KPIs, businesses should follow these best practices:

Define Clear Objectives: Identify what the organization aims to achieve and select metrics that align with these goals.

Use SMART Criteria: Ensure KPIs are Specific, Measurable, Achievable, Relevant, and Time-bound.

Monitor Regularly: Track metrics consistently to identify trends and address issues promptly.

Leverage Technology: Use dashboards and analytics tools to visualize data and simplify decision-making.

Encourage Collaboration: Share insights with teams to foster a culture of accountability and continuous improvement.

Callout: Regular reviews of KPIs help businesses adapt to changing market conditions and maintain alignment with strategic goals.

Real-World Example

A logistics company implemented KPIs to track delivery times and customer satisfaction. By analyzing data, the company identified delays caused by inefficient routing. After optimizing routes, delivery times improved by 25%, and customer satisfaction scores increased by 30%. This example highlights how metrics and KPIs can drive actionable insights and measurable results.

Metrics and KPIs serve as a compass for businesses, guiding them toward their goals. By using these tools effectively, organizations can ensure their processes remain efficient, adaptable, and aligned with their objectives.

Optimization of business processes remains a cornerstone for achieving efficiency and driving growth. By following structured steps—such as mapping workflows, analyzing inefficiencies, and embracing continuous improvement—businesses can unlock measurable benefits. These include enhanced productivity, reduced defects, and better resource utilization.

Improvement Area | Percentage Improvement |

|---|---|

Productivity | |

Defect Reduction | Up to 40% |

Operational Cost Reduction | 15-25% |

Resource Utilization Improvement | 30-40% |

Waste Reduction | 20-30% |

Taking the first step by evaluating current processes can reveal untapped potential. Businesses that prioritize optimization position themselves for long-term success. Now is the time to act, streamline operations, and achieve sustainable growth.

FAQ

What is the first step in optimizing business processes?

The first step involves identifying and mapping current workflows. This helps businesses understand how tasks are performed and highlights inefficiencies. Tools like SIPOC diagrams or workflow techniques provide a clear visual representation of processes, making it easier to pinpoint areas for improvement.

How does automation contribute to process optimization?

Automation eliminates repetitive tasks, reduces errors, and speeds up workflows. For example, automating data entry can save time and improve accuracy. Businesses can use tools like robotic process automation (RPA) to streamline operations and focus on high-value activities.

What industries benefit most from process optimization?

Industries like manufacturing, healthcare, retail, and finance see significant benefits. For instance, manufacturing firms reduce defects, while healthcare facilities improve patient wait times. Any industry with repetitive tasks or complex workflows can achieve measurable improvements through optimization.

How can businesses overcome resistance to change during optimization?

Clear communication and employee involvement reduce resistance. Leaders should explain the benefits of changes and provide training to ease transitions. Listening to employee concerns and incorporating their feedback fosters trust and encourages collaboration.

What role does technology play in process optimization?

Technology simplifies optimization by automating tasks, monitoring performance, and providing real-time insights. Tools like UiPath and Bonitasoft help businesses streamline workflows and make data-driven decisions. Technology also ensures scalability and adaptability in dynamic markets.

How often should businesses review their processes?

Businesses should review processes regularly, ideally every six months or after significant changes. Regular reviews ensure workflows remain efficient and aligned with organizational goals. Using methodologies like Lean or Agile helps maintain continuous improvement.

What are some common metrics used to track optimization success?

Common metrics include cycle time, error rates, customer satisfaction scores, and employee productivity. For example, tracking Net Promoter Score (NPS) measures customer loyalty, while monitoring task completion rates evaluates team efficiency.

Can small businesses benefit from process optimization?

Yes, small businesses can achieve significant gains. Streamlined workflows reduce costs, improve productivity, and enhance customer satisfaction. Simple tools like process mapping or low-cost automation solutions make optimization accessible for smaller organizations.

Tip: Start small by optimizing one process at a time to build momentum and confidence.