Six Sigma Methodology brings better results every time

Six Sigma Methodology drives better results by relying on disciplined, data-driven Systems that focus on reducing defects and improving quality. Across industries, organizations use this Methodology to address challenges and optimize Resources. The following table highlights how various sectors benefit from Six Sigma:

Industry | Example of Improvement |

|---|---|

Manufacturing | Decreasing rejects in parts machining processes |

Healthcare | Speeding up lab result delivery for faster treatment |

Finance & Banking | Increasing accuracy in account reconciliation |

Service | Raising first-call resolution rates in call centers |

IT & Software | Lowering software defects and debugging time |

Government | Streamlining permit processes to reduce backlogs |

Six Sigma reliably delivers better results for several reasons:

It uses a structured approach with the DMAIC framework.

It aligns improvement efforts with business goals.

It relies on data-driven decision-making.

It helps organizations control variations and reduce waste.

Key Takeaways

Six Sigma Methodology focuses on reducing defects and improving quality through a structured, data-driven approach.

The DMAIC framework—Define, Measure, Analyze, Improve, Control—guides teams in solving problems effectively.

Organizations across various industries, including manufacturing and healthcare, have reported significant improvements by implementing Six Sigma.

Data-driven decision-making is crucial; it helps teams identify issues and implement effective solutions.

Continuous improvement is a core principle of Six Sigma, ensuring that organizations adapt and enhance their processes over time.

Training and certification in Six Sigma tools empower employees to contribute to quality improvement efforts.

Leadership commitment and a culture of continuous improvement are essential for sustaining Six Sigma initiatives.

Small businesses can successfully implement Six Sigma to enhance efficiency and customer satisfaction without large investments.

Six Sigma Methodology Overview

Definition

Six Sigma Methodology provides a disciplined and data-driven approach to process improvement. Organizations use this method to solve problems when the solution is not already known. The process follows five main phases: define, measure, analyze, improve, and control.

According to ISO 13053-1:2011 – Quantitative methods in process improvement – Six Sigma – Part 1: DMAIC methodology, "Six Sigma projects should be undertaken only when the solution to a problem is not known." The methodology for Six Sigma includes five phases: define, measure, analyze, improve, and control (DMAIC).

This approach helps teams focus on facts and data instead of assumptions. By following a clear structure, Six Sigma Methodology supports consistent and repeatable results.

Principles

Six Sigma Methodology relies on several core principles that guide teams toward better quality and fewer errors. Each principle plays a key role in process improvement.

Contribution to Process Improvement | |

|---|---|

Define | Establishes clear objectives and scope for improvement. |

Measure | Quantifies current performance to identify gaps. |

Analyze | Identifies root causes of defects and variations. |

Improve | Implements solutions to enhance processes. |

Control | Maintains improvements and ensures consistency. |

Defect Reduction

Reducing defects stands at the heart of Six Sigma Methodology. Teams measure how often defects occur using a metric called Defects Per Million Opportunities (DPMO). A lower DPMO means fewer mistakes and more reliable results. For example, a pharmaceutical plant installed Poka-Yoke devices to prevent measurement errors. This change led to more uniform products and safer outcomes for patients. In another case, a delivery service improved its sorting and routing, which increased on-time deliveries and customer satisfaction.

Six Sigma Methodology aims to find and remove the root causes of defects. Teams believe that every process can be measured, analyzed, improved, and controlled. This belief drives continuous improvement and higher quality.

Data-Driven Approach

Data forms the foundation of every decision in Six Sigma Methodology. Teams collect and analyze data at each phase of the DMAIC process. This focus on measurement helps them understand where problems exist and how to fix them. By relying on data, organizations avoid guesswork and make changes that lead to real improvements.

History

The history of Six Sigma Methodology includes contributions from several key figures and organizations.

Contribution/Role | |

|---|---|

William Bill Smith | Developed the Six Sigma concept at Motorola and is considered the father of Six Sigma. |

Mikel Harry | Collaborated with Bill Smith to create the Six Sigma methodology and its problem-solving approach. |

Motorola | First company to implement Six Sigma and won the Malcolm Baldrige Award for its success. |

Walter Shewhart | Early pioneer of statistical quality control, influencing the foundations of Six Sigma. |

Jack Welch | CEO of General Electric who popularized Six Sigma in the corporate culture, leading to significant improvements. |

Bill Smith and Mikel Harry developed Six Sigma at Motorola in the 1980s.

Walter Shewhart's earlier work on statistical quality control laid the groundwork for Six Sigma.

Motorola's success with Six Sigma led to the company receiving the Malcolm Baldrige Award.

Jack Welch implemented Six Sigma at General Electric, significantly enhancing the company's performance.

The development of Six Sigma Methodology was shaped by these innovators. Bill Smith and Mikel Harry created a structured approach at Motorola, focusing on statistical analysis to reduce defects. Walter Shewhart's work in quality control provided the foundation for these ideas. When Jack Welch introduced Six Sigma at General Electric, the method gained worldwide attention and proved its value in many industries.

DMAIC Framework

The DMAIC framework forms the backbone of Six Sigma Methodology. It guides teams through a structured process to solve problems and improve quality. Each phase—Define, Measure, and Analyze—plays a unique role in ensuring reliable and repeatable results.

Define

The Define phase sets the stage for a successful project. Teams clarify the problem and align their efforts with organizational goals. This phase ensures everyone understands the purpose and direction of the improvement effort.

Problem Definition: Teams clearly define the problem or opportunity for improvement. The problem must be measurable and connected to business objectives.

Goal Setting: Teams establish specific, measurable, achievable, relevant, and time-bound (SMART) goals. These goals provide a clear target for the project.

Project Scope: Teams identify the boundaries of the project. This step helps manage expectations and keeps the team focused.

Stakeholder Identification: Teams recognize key stakeholders and understand their needs and expectations.

High-Level Process Mapping: Teams create a process map to visualize the workflow. This map highlights areas that may need improvement.

The Define phase lays the groundwork for the entire DMAIC process. By articulating the problem, setting clear goals, and identifying stakeholders, teams ensure a focused and effective improvement effort. This foundation is crucial for achieving sustainable results.

Measure

The Measure phase focuses on collecting data to understand the current state of the process. Teams gather information to establish a baseline and identify where problems exist.

The measure phase is all about collecting as much data as possible to get the actual picture of the problem. Hence, the team must ensure the data collection measurement process is accurate and precise.

Teams collect both qualitative and quantitative data. This information helps them see how the process performs and where gaps appear.

Discrete data: Counts such as the number of defects or customer complaints.

Continuous data: Measurements like cycle time or processing speed.

During this phase, teams use data to gain insights into the process. Accurate measurement ensures that any changes made later can be tracked and evaluated. This step supports data-driven decisions and helps teams focus on real issues.

Analyze

The Analyze phase helps teams find the root causes of problems. By using analytical tools, teams move beyond symptoms and discover what truly drives defects or inefficiencies.

Analytical Tool | Description |

|---|---|

Cause-and-effect diagrams | Also known as fishbone or Ishikawa diagrams, these help visualize potential causes of defects. |

5 Whys | A method that involves asking 'why' multiple times to drill down to the root cause. |

Hypothesis Testing | Techniques like T-Tests and ANOVA to determine statistical significance of causes. |

Correlation/Regression Analysis | Analyzes relationships between variables to identify significant factors. |

Design of Experiments (DOE) | A structured approach to determine the relationship between factors and responses. |

Process Capability Analysis | Evaluates how well a process meets specified limits and identifies areas for improvement. |

Teams use these tools to analyze data and identify patterns. By understanding the root causes, teams can develop targeted solutions. This phase ensures that improvements address the real issues, not just the symptoms.

The DMAIC framework provides a clear roadmap for process improvement. Its structured phases, focus on data, and use of analytical tools lead to reliable and repeatable outcomes. Six Sigma Methodology uses this disciplined approach to drive measurable results and enhance operational efficiency.

Improve

The Improve phase transforms analysis into action. Teams focus on finding and implementing solutions that address the root causes identified earlier. This phase uses creativity, data, and structured decision-making to ensure changes lead to real improvements.

Teams often begin with brainstorming. They gather ideas from different team members to generate a wide range of possible solutions. Design of Experiments (DOE) and simulation help test these ideas in a controlled way. These tools allow teams to predict how changes will affect the process before making large-scale adjustments.

Tip: Teams should encourage open discussion during brainstorming. Every idea counts, even if it seems unusual at first.

A structured approach helps teams move from ideas to action. The following table outlines proven strategies for implementing improvements:

Strategy | Description |

|---|---|

Identify feasible solutions | Determine solutions that address the root cause(s) identified in previous phases. |

Select the best solution | Use statistical tools to evaluate and choose the most effective solution. |

Perform cost-benefit analysis | Analyze the financial implications of the proposed solutions to ensure they are viable. |

Test the solution | Implement a trial of the solution to observe its effectiveness in a controlled environment. |

Assess effectiveness | Measure the outcomes of the solution to confirm it leads to measurable improvements in the process. |

Teams use several methods to organize and select solutions:

Use clarification, duplication, and categorization to organize potential solutions.

Apply multi-voting to select a set of solutions.

Use must and want criteria to prioritize the order of solutions for implementation.

After selecting the best solution, teams often run a pilot test. This small-scale trial helps them see if the solution works as expected. They measure the results and compare them to the original goals. If the solution proves effective, the team prepares for full implementation.

The Improve phase ensures that changes are not only creative but also practical and data-driven. By testing and measuring each step, teams increase the chances of lasting success.

Benefits

Efficiency

Teams and organizations often see major gains in efficiency after adopting Six Sigma Methodology. This approach helps systems identify waste, streamline processes, and boost productivity. By focusing on data and structured problem-solving, teams can optimize their workflows and deliver better results for clients. The following table highlights specific improvements reported by organizations:

Improvement Category | Specific Improvements |

|---|---|

Operational Efficiency | Waste reduction, Cycle time improvements, Capacity optimization, Productivity increases |

Quality Enhancement | Defect rate reduction, Process consistency, Root cause elimination, Reliability increases |

Cost Reduction | Operating expense reduction, Quality cost decreases, Resource utilization improvement, Profitability enhancement |

Customer Satisfaction | Product and service quality enhancement, Delivery time improvement, Service consistency, Overall satisfaction increases |

These improvements show that Six Sigma Methodology does more than just cut costs. It helps teams work smarter, not harder. Clients benefit from faster delivery times and more reliable products or services.

Error Reduction

Reducing errors stands as a core benefit of Six Sigma Methodology. Teams use data to find the root causes of mistakes and then fix them. This focus on error reduction leads to safer, higher-quality outcomes for both organizations and their clients.

In healthcare, a hospital system used Six Sigma to significantly reduce medication errors, enhancing patient safety.

An automotive manufacturer applied Six Sigma to their welding process, leading to substantial cost savings and improved customer satisfaction.

A project focused on rubber weather strips in the automotive industry reduced the rejection rate from 5.5% to 3.08%, saving costs and improving quality.

These examples show how teams in different industries can achieve measurable error reduction. Clients receive safer products and services, while organizations build stronger reputations for quality.

Cost Savings

Cost savings often follow when teams improve efficiency and reduce errors. Six Sigma Methodology helps organizations use resources wisely and cut unnecessary expenses. The results can be dramatic, especially for large companies. The table below shows some well-known examples:

Source | Savings | Description |

|---|---|---|

iSixSigma Magazine | Estimated savings for Fortune 500 companies over 20 years | |

GE Annual Report | $10 billion | Savings in the first five years of Six Sigma implementation for GE |

iSixSigma Magazine | 2% of revenue | Average annual savings from corporate-wide Six Sigma deployments |

GE reported an addition of $300 million to its bottom line due to Six Sigma.

In its first five years, Six Sigma saved GE approximately $10 billion.

These numbers show that both large and small organizations can benefit. Teams that use Six Sigma Methodology often find new ways to save money, which can lead to lower prices for clients and more funds for future growth.

Customer Satisfaction

Six Sigma Methodology places a strong focus on meeting customer needs. Teams use data to understand what clients expect and then work to deliver consistent results. When organizations improve their processes, customers notice better service, higher quality, and faster response times.

Many companies have seen measurable gains in customer satisfaction after adopting Six Sigma. The following examples show how different industries achieved these results:

A telecommunications company reduced average wait times by 40%. The team also increased first-call resolution rates by 25%. These changes led to significant improvements in customer satisfaction scores.

A plumbing product distributor improved delivery efficiency. This change addressed customer dissatisfaction and enhanced the company’s reputation.

An Indian manufacturing company raised its sigma level from 3.9 to 4.45. The team significantly reduced the rejection rate of rubber weather strips, helping the company meet customer expectations.

Ford eliminated over $2.19 billion in waste. The company also increased customer satisfaction scores by five points through Lean Six Sigma techniques.

Teams achieve these results by listening to customer feedback and analyzing data. They identify pain points, such as long wait times or product defects, and then use the DMAIC framework to solve these problems. Each improvement cycle brings the process closer to what customers want.

Note: Satisfied customers often become repeat buyers and recommend the company to others. High satisfaction scores can lead to stronger brand loyalty and long-term business growth.

Systems play a key role in maintaining these improvements. Automated checks, clear process maps, and regular reviews help teams deliver consistent quality. Clients benefit from fewer errors, faster service, and products that meet their needs every time.

Six Sigma Methodology helps organizations build trust with their customers. By focusing on quality and reliability, teams create positive experiences that set their company apart from competitors.

Applications

Manufacturing

Manufacturing companies have used Six Sigma Methodology to achieve remarkable improvements in quality and efficiency. Teams in this sector focus on reducing defects, cutting costs, and increasing productivity. They rely on data-driven systems to identify problems and implement solutions that last.

Many well-known organizations have reported measurable gains after adopting Six Sigma. For example, Motorola achieved a tenfold improvement in quality across all divisions within five years. This success helped establish Six Sigma as a leading approach in manufacturing. Other companies have also seen significant results:

Company/Project | Outcome | Description |

|---|---|---|

Motorola | Tenfold improvement in quality | Achieved significant quality enhancements across all divisions within five years, laying the groundwork for Six Sigma's rise. |

Food Processing Equipment Manufacturer | Saved $240,000 in annual warranty claims | Implemented Lean Six Sigma principles to improve warranty claims process, resulting in reduced cycle time and cost savings. |

Kern County Probation Department | Saved $400,000 in labor hours | Utilized Lean Six Sigma methodologies to enhance operational efficiency. |

Tennessee Valley Authority | Closed a budget gap of $21 million | Applied Lean Six Sigma to address financial inefficiencies. |

Teams in manufacturing use Six Sigma to streamline production lines, improve product consistency, and reduce waste. These improvements help clients receive higher-quality products and faster delivery times. The repeatable nature of Six Sigma ensures that gains are not one-time events but become part of the company’s standard operations.

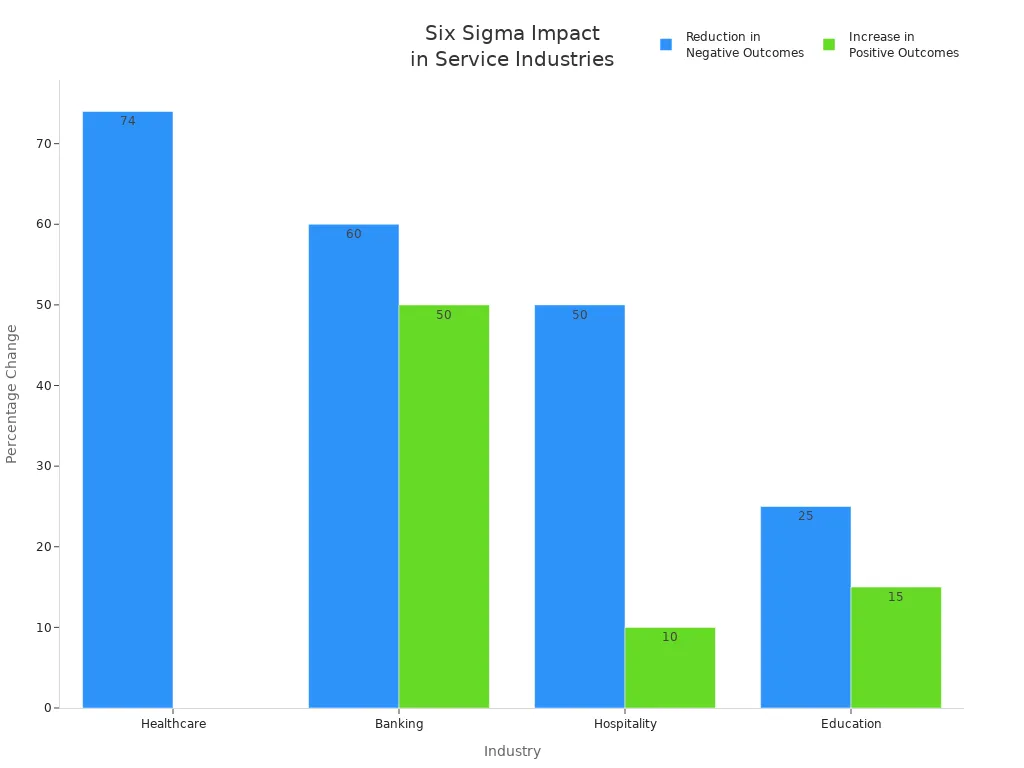

Services

Service industries, such as banking, hospitality, and education, have also benefited from Six Sigma Methodology. Teams in these sectors use data to improve customer experiences, speed up processes, and reduce errors. The approach adapts well to both large organizations and smaller service providers.

Several case studies highlight the effectiveness of Six Sigma in services:

Industry | Case Study Description | Results |

|---|---|---|

Healthcare | A US hospital implemented Lean Six Sigma to reduce SSIs. | 74% reduction in SSIs, improved care quality, and cost savings. |

Banking | An Indian bank used Lean Six Sigma to enhance loan application processes. | 60% reduction in turnaround time, 50% increase in loans approved, 20% increase in customer satisfaction. |

Hospitality | A UK hotel chain applied Lean Six Sigma to improve customer experience. | 50% reduction in complaints, 10% increase in NPS, over £1 million in cost savings. |

Education | A US university utilized Lean Six Sigma to improve online course completion rates. | 25% reduction in dropout rates, 15% increase in completion rates, 10% increase in student satisfaction. |

Teams in service industries often use Six Sigma to map out processes, identify bottlenecks, and create solutions that improve both speed and quality. Clients benefit from shorter wait times, fewer mistakes, and better overall experiences.

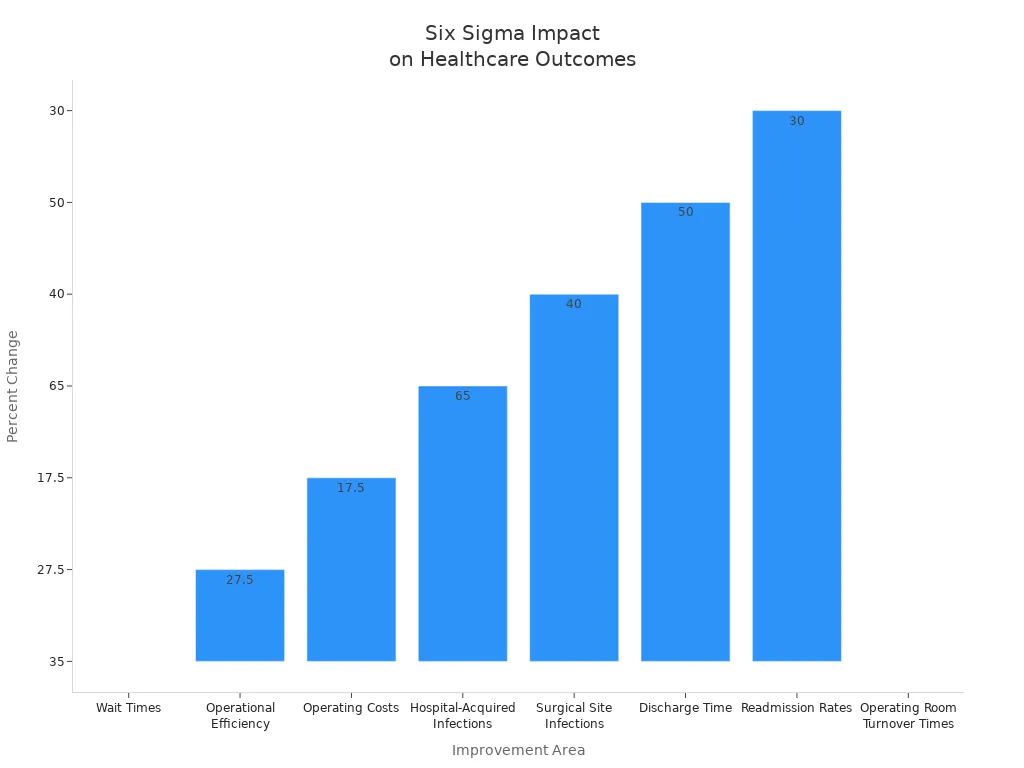

Healthcare

Healthcare organizations have turned to Six Sigma to improve patient outcomes and operational efficiency. Teams in hospitals and clinics use data to reduce errors, lower costs, and enhance patient satisfaction. The methodology supports a culture of continuous improvement, which is vital in healthcare settings.

Hospitals have reported impressive results after implementing Six Sigma projects:

Improvement Area | Documented Results |

|---|---|

Wait Times | |

Patient Satisfaction | Improved HCAHPS scores |

Operational Efficiency | 25-30% improvement in throughput |

Operating Costs | 15-20% reduction in operating costs |

Hospital-Acquired Infections | 65% reduction in central line infections |

Surgical Site Infections | 40% decrease in surgical site infections |

Discharge Time | 50% reduction in discharge time |

Readmission Rates | 30% decrease in readmission rates |

Operating Room Turnover Times | 35% reduction in turnover time |

Annual Cost Savings | $2.1 million annual cost savings |

Teams in healthcare use Six Sigma to standardize procedures, reduce infection rates, and speed up patient care. These changes lead to safer environments and better experiences for patients. The repeatable success of Six Sigma in healthcare shows its value across different types of organizations.

Small Business

Small businesses often face challenges with limited resources and tight budgets. Six Sigma Methodology offers a practical solution for these organizations. Teams in small companies use Six Sigma to improve efficiency, reduce waste, and deliver better products or services. The approach helps them compete with larger firms by focusing on measurable improvements.

Many small businesses have achieved significant results by adopting Six Sigma. They see changes in sales, delivery times, and overall process reliability. The following examples highlight how Six Sigma makes a difference:

A small business increased annual sales by $248,034 after streamlining its order fulfillment process.

The same company reduced delivery time by more than four full days, which improved customer satisfaction.

Teams use Six Sigma to identify and eliminate waste in daily operations.

The methodology reduces variability and boosts efficiency across departments.

Companies evaluate the accuracy and reliability of their measurement systems to ensure consistent results.

Teams assess sources of variation in measurement data, leading to better decision-making.

Small businesses benefit from Six Sigma because the methodology adapts to different industries and team sizes. Owners and managers often start with simple tools, such as process mapping and root cause analysis. These tools help them find problems and create solutions that fit their needs.

Tip: Small business teams should focus on one process at a time. This approach makes improvements easier to manage and measure.

The table below shows common areas where small businesses apply Six Sigma and the results they achieve:

Area of Improvement | Typical Results |

|---|---|

Order Fulfillment | Faster delivery, fewer errors |

Inventory Management | Lower costs, reduced waste |

Customer Service | Higher satisfaction, quicker response |

Quality Control | More reliable products, fewer defects |

Financial Processes | Improved accuracy, better cash flow |

Six Sigma also helps small businesses build a culture of continuous improvement. Employees learn to use data when making decisions. They track progress and celebrate small wins, which keeps motivation high.

Small business owners see that Six Sigma does not require expensive technology or large teams. They can start with basic training and simple projects. Over time, these efforts lead to repeatable success and stronger performance.

Six Sigma Methodology gives small businesses the tools to grow and thrive. By focusing on data and process improvement, they deliver better results for customers and stay competitive in their markets.

Implementation

Getting Started

Organizations that want to adopt Six Sigma Methodology should follow a series of practical steps. These steps help set a strong foundation for success:

Creation of a Burning Point: Leaders identify clear reasons for change, such as high defect rates or customer complaints.

Bring Resources in Place: Teams gather the right people and materials needed for the project.

Let the Team Learn the Technique: Members receive training to understand Six Sigma tools and concepts.

Prioritize Activities: Teams align improvement projects with business goals and customer needs.

Establish Ownership: Leaders assign responsibility for the Six Sigma initiative to specific individuals or teams.

Taking the Right Measurements: Teams set up systems to track progress and measure results.

Governing the Program: Organizations create oversight structures to guide and monitor the implementation.

Rewards Contributions: Leaders recognize and reward team members who drive improvements.

Tip: Starting with a pilot project can help teams learn and build confidence before expanding Six Sigma efforts across the organization.

Training

Training prepares employees to participate in Six Sigma projects and manage changes. Well-designed programs help reduce resistance and build skills for success. Organizations often use a mix of certification courses and hands-on learning.

Training Program | Description |

|---|---|

Prepares mid-level professionals to lead improvement projects. | |

Lean Six Sigma Black Belt Certification | Trains professionals to manage complex, high-impact projects. |

Lean Fundamentals Certification | Introduces Lean principles and basic practices. |

Lean IT Certification | Focuses on Lean methods for IT environments. |

7QC Tools Certification | Covers the seven essential quality control tools. |

Value Stream Mapping Certification | Teaches mapping and analysis of process flows. |

Many organizations also offer:

White Belt Virtual Training for beginners

Green Belt and Black Belt Virtual Training for advanced roles

Hands-on coursework with real-world projects

Access to instructors for ongoing support

Training ensures that everyone understands their role and can use Six Sigma tools effectively.

Best Practices

Sustaining improvements over time requires a set of best practices. These practices help organizations maintain gains and encourage ongoing progress:

Leadership Commitment: Leaders support and model Six Sigma principles.

Build a Culture of Continuous Improvement: Every employee takes part in finding better ways to work.

Standardize Processes: Teams document new procedures and create standard operating procedures.

Training and Skill Development: Organizations invest in ongoing learning for all team members.

Metrics and Key Performance Indicators (KPIs): Teams use clear measurements to track progress.

Cross-Functional Teams: Departments work together and share lessons learned.

Management Review and Feedback: Leaders review progress and provide feedback regularly.

Celebrate Successes: Teams recognize and reward achievements.

Continuous Monitoring and Auditing: Organizations check processes regularly to ensure improvements last.

Lean Six Sigma Office (LSO): Some companies set up a dedicated office to oversee projects.

Customer Feedback: Teams gather and analyze feedback to guide future improvements.

Continuous Training and Certification: Employees pursue further certifications to deepen their skills.

Note: Following these best practices helps organizations achieve lasting results and build a culture that values quality and improvement.

Challenges

Organizations often encounter several challenges when implementing Six Sigma Methodology. These obstacles can slow progress or even cause projects to fail if not addressed early. Understanding these common issues helps teams prepare and respond effectively.

Common Challenges in Six Sigma Implementation:

Lack of Leadership Commitment: Success depends on strong support from top management. Leaders must dedicate skilled personnel and resources to Six Sigma projects. Without this commitment, teams may struggle to gain traction.

Incomplete Understanding of Six Sigma: Some organizations begin projects without fully grasping the methodology. This gap can lead to confusion and poor results. Companies should invest in expert guidance and thorough training.

Poor Execution: Projects sometimes lose focus or drift away from business goals. Teams need to align every Six Sigma effort with the organization’s strategic objectives to ensure relevance and impact.

Resistance to Change: Employees may feel uncertain or threatened by new processes. Early education and involvement help reduce resistance. When staff understand the benefits, they become more willing to participate.

Lack of Expertise and Trained Personnel: Teams without proper training may struggle to use Six Sigma tools. Investing in certification and hiring experienced practitioners builds internal capability.

Resource Constraints: Smaller organizations or those with tight budgets may find it hard to allocate time and money. Starting with small, focused projects can demonstrate value and build support for larger efforts.

Difficulty Sustaining Improvements: Some companies see early gains but struggle to maintain momentum. Embedding Six Sigma into the company culture supports long-term success.

Misalignment with Organizational Goals: Projects that do not match business priorities may lose support. Teams should ensure every initiative aligns with strategic plans.

Data Collection and Analysis Issues: Reliable data is essential for Six Sigma. Teams need clear protocols and effective tools for gathering and analyzing information.

Setting Realistic Expectations: Teams sometimes expect rapid, dramatic results. Setting incremental milestones and celebrating small wins keeps motivation high.

Tip: Teams can overcome most challenges by planning carefully, investing in training, and maintaining open communication.

The table below summarizes key challenges and practical solutions:

Challenge | Solution |

|---|---|

Leadership Commitment | Secure executive sponsorship |

Incomplete Understanding | Provide comprehensive training |

Resistance to Change | Involve employees early, communicate benefits |

Lack of Expertise | Hire or train Six Sigma professionals |

Resource Constraints | Start with pilot projects |

Sustaining Improvements | Integrate Six Sigma into company culture |

Data Collection Issues | Use reliable tools and clear protocols |

Misalignment with Goals | Align projects with strategic objectives |

Unrealistic Expectations | Set achievable milestones |

By recognizing and addressing these challenges, organizations can improve their chances of successful Six Sigma implementation and achieve lasting results.

Comparison

Lean

Lean and Six Sigma both aim to improve processes, but they focus on different areas. Lean seeks to eliminate waste and maximize value for the customer. Teams using Lean look for steps in a process that do not add value. They remove these steps to make the process faster and more efficient. Lean uses qualitative methods to identify waste, such as unnecessary movement or waiting time.

Six Sigma, on the other hand, targets defects and variability. Teams use statistical analysis to find and reduce errors. The goal is to achieve near-perfect quality, with only 3.4 defects per million opportunities. Six Sigma relies on data and measurement to drive improvements.

Methodology | Primary Objective | Key Goals |

|---|---|---|

Lean | Reduce waste, streamline processes, improve customer satisfaction | |

Six Sigma | Reduce defects and variability in processes | Achieve near-perfect quality, improve process consistency, reduce costs |

In Lean, waste means any activity that does not add value for the customer. In Six Sigma, waste often comes from variation in the process. This difference shapes how each method approaches improvement.

Lean: Focuses on removing waste and improving flow.

Six Sigma: Concentrates on reducing defects and making processes more consistent.

TQM

Total Quality Management (TQM) and Six Sigma share a commitment to quality, but their approaches differ. TQM takes a broad, philosophy-based approach. It encourages everyone in the organization to seek continuous improvement. TQM does not focus on specific projects. Instead, it aims for gradual, long-term change across all areas.

Six Sigma uses a data-driven method. Teams work on specific projects with clear goals. They use statistical tools to measure and reduce defects. Six Sigma often involves specialized roles, such as Green Belts and Black Belts.

Aspect | Six Sigma | Total Quality Management (TQM) |

|---|---|---|

Methodology | Data-driven, reduces defects and variability | Philosophy-based, continuous improvement |

Focus | Near perfection (3.4 defects per million) | Improvement in all areas |

Implementation | Project-specific, measurable goals | Holistic, not project-specific |

Employee Involvement | Specialized roles | All employees involved |

Measurement | Statistical data, defect rates | Customer satisfaction, overall quality |

Timeframe | Short-term, project-based | Long-term, gradual |

Six Sigma stands out for its use of data and focus on measurable results. TQM builds a culture of quality over time.

Choosing Six Sigma

Organizations should consider several factors when choosing a quality improvement method. Team involvement plays a key role. Some methods, like 8D, encourage group collaboration. Six Sigma’s DMAIC framework often assigns tasks to individuals with specialized training.

Data availability matters. Six Sigma works best when teams can collect and analyze large amounts of data. Other methods, such as 8D, can adapt to situations with less data.

Organizational needs also guide the choice. Leaders should match the method to their company’s culture, goals, and resources. Six Sigma fits organizations that want measurable, project-based improvements and have the resources for training and data analysis.

Tip: Teams should review their goals and resources before selecting a method. The right choice leads to better results and lasting improvements.

Trends

Digital Integration

Digital tools have changed how organizations use Six Sigma Methodology. Many companies now use cloud-based platforms for real-time data collection. These platforms help teams gather information quickly and share it with everyone involved. Advanced analytics software allows teams to find the root causes of problems faster and with greater accuracy. This technology helps organizations solve issues before they grow larger.

Organizations that use digital tools in their Six Sigma programs finish projects 37% faster than those using older methods. This speed comes from better access to data and improved communication. Companies also report a 30% reduction in cycle times when they use advanced analytics in their projects. These results show that digital integration leads to more efficient and effective process improvements.

Note: Digital integration in Six Sigma not only speeds up projects but also improves the quality of decisions by providing accurate, real-time data.

Evolving Roles

The roles within Six Sigma teams have changed as organizations adopt new tools and face new challenges. Team members now need both technical and leadership skills. The responsibilities for each belt level have become more defined, as shown in the table below:

Belt Level | Role | Responsibilities |

|---|---|---|

Yellow Belt | Fundamental knowledge of Six Sigma | Contribute to projects and assist with process improvements. |

Green Belt | Intermediate Six Sigma expertise | Lead small-scale projects and apply DMAIC tools. |

Black Belt | Advanced Six Sigma proficiency | Manage complex projects and mentor Green Belts. |

Master Black Belt | Organizational leadership and strategy | Oversee implementation, mentor Black Belts, align strategy with business goals. |

Team members now focus on several key tasks:

Facilitate communication and collaboration among all members.

Identify and prioritize opportunities for improvement.

Ensure the effective use of Lean Six Sigma tools.

Support the removal of barriers that could block project success.

These evolving roles help teams work together more effectively and achieve better results.

Continuous Improvement

Continuous improvement remains a core trend in Six Sigma Methodology. Teams use feedback and data to make small changes that add up over time. This approach helps organizations stay competitive and adapt to new challenges.

Many companies now use digital dashboards to track progress and spot areas for improvement. Teams review these dashboards regularly to find trends and set new goals. By focusing on ongoing improvement, organizations can respond quickly to customer needs and market changes.

Tip: Teams that embrace continuous improvement build a culture where everyone looks for ways to make things better. This mindset leads to lasting success and higher quality in every process.

Six Sigma Methodology gives organizations a proven way to improve quality and reduce errors. Teams see better results because they follow a clear, data-driven process. Companies that use this approach often find higher efficiency and stronger customer satisfaction.

Many leaders choose Six Sigma Methodology to support ongoing improvement.

For those interested in learning how systems and teams can drive better results, reaching out for more information can be a great next step.

FAQ

What is the main goal of Six Sigma?

Six Sigma aims to improve process quality by reducing defects and variation. Teams use data and structured methods to achieve consistent, reliable results.

Who can benefit from Six Sigma Methodology?

Manufacturers, service providers, healthcare organizations, and small businesses all benefit from Six Sigma. Any group seeking better quality and efficiency can apply its principles.

How does Six Sigma differ from Lean?

Lean focuses on removing waste and speeding up processes. Six Sigma targets defect reduction and process consistency. Many organizations combine both for greater results.

What are the belt levels in Six Sigma?

Belt Level | Typical Role |

|---|---|

Yellow Belt | Team member |

Green Belt | Project leader |

Black Belt | Project manager |

Master Black Belt | Program strategist |

Each level brings different skills and responsibilities.

Does Six Sigma require advanced math skills?

Most team members use basic statistics and simple tools. Black Belts and Master Black Belts may use more advanced analysis, but training covers these skills.

Can small businesses use Six Sigma?

Yes! Small businesses often start with simple projects and basic tools. They see improvements in quality, speed, and customer satisfaction without large investments.

How long does a typical Six Sigma project take?

Project length varies. Many projects finish in three to six months. The timeline depends on project scope, team experience, and available resources.

Is Six Sigma only for manufacturing?

No. Service industries, healthcare, finance, and even education use Six Sigma. The methodology adapts to many types of processes and organizations.