Selecting and Applying Business Process Improvement Methodologies for Success

Selecting the right business process improvement methodologies drives success by matching each approach to strategic objectives. Organizations that align methodology choice with their goals use resources more effectively. They increase efficiency and deliver better experiences for clients and customers. Teams that follow structured optimization steps often eliminate waste, reduce costs, and improve profitability. Reflection on current processes and readiness for change helps leaders build a culture of adaptability and continuous improvement.

Key Takeaways

Selecting the right business process improvement methodology aligns with your organization's strategic goals.

Business Process Improvement Methodologies help identify inefficiencies and enhance workflows for better results.

Common methodologies include Six Sigma, Lean, TQM, and Agile, each with unique strengths and ideal use cases.

Overcoming challenges like resistance to change and lack of training is crucial for successful implementation.

A structured assessment of needs and goals guides the selection of the most suitable methodology.

Building cross-functional teams enhances collaboration and improves problem-solving during process improvements.

Regular monitoring of key performance indicators ensures that improvements remain effective and sustainable.

Using a decision matrix simplifies the selection process by comparing methodologies based on relevant criteria.

What Are Business Process Improvement Methodologies?

Definition and Purpose

Business Process Improvement Methodologies refer to structured approaches that organizations use to analyze, redesign, and enhance their business processes. These methodologies help companies identify inefficiencies, optimize workflows, and achieve operational excellence. The primary purpose centers on improving efficiency, reducing waste, increasing quality, and boosting satisfaction for both customers and employees.

Tip: Organizations often use these methodologies to drive competitive advantage and support long-term growth.

Industry experts highlight several main goals for these approaches:

Reduce waste

Improve quality

Increase satisfaction

A typical process improvement journey follows these steps:

Identify inefficiencies

Optimize processes

Drive operational excellence

Achieve competitive advantage

Why Selection Matters

Choosing the right methodology can make a significant difference in outcomes. Each approach offers unique strengths and fits different business needs. For example, Six Sigma focuses on reducing defects through data-driven analysis, while Lean manufacturing aims to eliminate waste and streamline operations. Total Quality Management (TQM) involves all employees in the pursuit of quality improvement.

Organizations that select the most suitable methodology often see better results. Tim Hortons, for instance, used Lean techniques to optimize its supply chain and manage staffing based on customer demand. Fortune 500 companies have saved billions by applying Lean Six Sigma, demonstrating the financial impact of effective methodology selection. Research shows that combining Lean and Six Sigma delivers the most effective process improvement.

Methodology | Main Focus | Typical Benefit |

|---|---|---|

Six Sigma | Reduce defects | Higher quality |

Lean | Eliminate waste | Greater efficiency |

TQM | Organization-wide quality | Improved consistency |

Kaizen | Continuous improvement | Ongoing progress |

PDCA | Cyclical improvement | Sustainable change |

Common Challenges

Organizations face several challenges when implementing Business Process Improvement Methodologies. Teams may struggle with resistance to change, lack of clear goals, or insufficient training. Sometimes, companies choose a methodology that does not fit their culture or resources, leading to poor results.

Common obstacles include:

Difficulty in gaining employee buy-in

Limited understanding of methodology steps

Inadequate resources for implementation

Misalignment with organizational goals

Note: Addressing these challenges early increases the chances of successful process improvement and lasting benefits.

Many organizations overcome these hurdles by investing in training, communicating the benefits, and aligning improvement efforts with strategic objectives.

Types of Business Process Improvement Methodologies

Six Sigma

Strengths and Limitations

Six Sigma stands out as a data-driven approach that targets defect reduction and process variation. Organizations use statistical tools and the DMAIC framework (Define, Measure, Analyze, Improve, Control) to guide improvement projects. Six Sigma provides clear certification levels, such as Green Belt and Black Belt, which help teams build expertise. This methodology delivers measurable results and supports a culture of quality.

However, Six Sigma can require significant training and resources. Some teams find the statistical analysis complex. Six Sigma often works best in environments with well-defined processes and available data. It may not suit organizations that need rapid changes or have limited resources.

Ideal Use Cases

Companies apply Six Sigma in manufacturing, healthcare, and finance. It fits projects that need defect reduction and process consistency. Six Sigma works well for organizations seeking to improve product quality or customer satisfaction through data analysis.

Lean

Strengths and Limitations

Lean focuses on eliminating waste and creating value for customers. Teams use tools like value stream mapping and 5S to streamline workflows. Lean encourages a process-centered approach and supports continuous improvement. Many organizations adopt Lean as an enterprise philosophy, which helps build a culture of efficiency.

Lean may not address process variation as deeply as Six Sigma. Some teams struggle to sustain Lean improvements without ongoing leadership support. Lean does not use a belt certification system, which can make skill development less formal.

Aspect | Lean | Six Sigma |

|---|---|---|

Origins | Developed from Toyota's production system | Developed by Motorola |

Primary Goals | Reduce waste and create value | Reduce variation and defects |

Tools Used | Value stream mapping, 5S, etc. | DMAIC, statistical analysis |

Improvement Approach | Process-focused | Project-based |

Emphasis | Flow and pull | Measuring and analyzing |

Certification Levels | No belt system | Belts like Green Belt, Black Belt |

Deployment | Enterprise philosophy | Often departmental |

Lean fits organizations that want to improve flow and reduce unnecessary steps. Six Sigma suits teams that need to measure and analyze defects.

Ideal Use Cases

Lean works best in industries like manufacturing, retail, and logistics. Teams use Lean to simplify processes, reduce delays, and increase customer value. Lean fits organizations that want to build a culture of continuous improvement.

Lean Six Sigma

Strengths and Limitations

Lean Six Sigma combines the strengths of Lean and Six Sigma. Organizations benefit from Lean’s customer orientation and waste elimination, along with Six Sigma’s statistical tools and defect reduction strategies. This hybrid approach creates robust processes and supports a strong quality culture. Lean Six Sigma engages frontline staff and promotes teamwork.

Some organizations find Lean Six Sigma complex to implement. Training requirements can be high. Teams must balance process speed with data analysis.

Ideal Use Cases

Lean Six Sigma fits organizations that need both efficiency and quality improvement. Healthcare, manufacturing, and service industries use Lean Six Sigma to improve metrics and increase customer satisfaction. Studies show Lean Six Sigma works well for supply chain, operational management, and quality control. Teams use it to improve linen operations, sanitation, and waste management. Lean Six Sigma serves as a flexible framework for Business Process Improvement Methodologies at different organizational levels.

Total Quality Management (TQM)

Strengths and Limitations

Total Quality Management (TQM) encourages organizations to focus on quality in every process and at every level. Teams work together to improve products, services, and internal operations. TQM builds a culture where everyone feels responsible for quality. This approach often leads to better customer satisfaction and consistent results.

TQM offers several strengths:

It promotes organization-wide involvement.

It supports long-term improvement.

It helps standardize processes.

However, TQM also faces limitations. Many managers do not fully understand how to implement TQM. Adoption rates vary across industries. For example, a survey of 300 architectural, engineering, and contracting firms found that most top managers lacked understanding of TQM. Only 32% of organizations in the survey had implemented TQM, while 68% used other quality assurance or control systems. The construction industry often lags in TQM adoption because many believe it suits manufacturing and service sectors better.

Strengths | Limitations |

|---|---|

Organization-wide focus | Low adoption in some industries |

Standardized processes | Misconceptions about applicability |

Long-term improvement | Requires strong leadership and training |

Ideal Use Cases

TQM works best in organizations that want to improve quality across all departments. Manufacturing and service industries often use TQM to deliver consistent products and services. Companies with strong leadership and a commitment to training see the most success. TQM fits businesses aiming for continuous improvement and customer satisfaction.

Continuous Improvement (Kaizen)

Strengths and Limitations

Continuous Improvement, known as Kaizen, encourages small, ongoing changes. Teams look for ways to improve daily tasks and processes. Kaizen builds a culture of teamwork and adaptability. Employees feel empowered to suggest improvements.

Kaizen offers many benefits:

Improved production quality

Increased productivity

Better health and safety

Greater team involvement

Reduced costs

A mid-sized manufacturing company in the Midwest reported $2.5 million in savings after 18 months of using basic continuous improvement methods. Kaizen also leads to higher quality, improved employee engagement, enhanced innovation, and greater customer loyalty.

Kaizen requires commitment from all levels. Some organizations struggle to maintain momentum. Without regular feedback, improvements may slow down.

Ideal Use Cases

Kaizen fits organizations that want ongoing progress. Manufacturing, healthcare, and service industries use Kaizen to boost efficiency and quality. Teams that value employee input and want to adapt quickly benefit most from this approach.

Plan-Do-Check-Act (PDCA)

Strengths and Limitations

The Plan-Do-Check-Act (PDCA) cycle provides a simple framework for continuous improvement. Teams plan changes, implement them, check results, and act on findings. PDCA fosters a culture of learning and adaptation.

PDCA has proven effective on factory floors worldwide for nearly a century. Manufacturing and service industries use PDCA to improve processes and customer experience. The cycle helps organizations enhance efficiency, quality, and adaptability.

Strengths of PDCA include:

Easy to understand and apply

Supports ongoing improvement

Works in many industries

Limitations may arise if teams skip steps or fail to review results. PDCA requires discipline and regular evaluation.

Ideal Use Cases

PDCA suits organizations seeking a structured approach to improvement. Manufacturing companies use PDCA to maintain efficient operations and low costs. Service industries apply PDCA to improve customer experience and process reliability. Teams that want to build a habit of reviewing and refining their work find PDCA valuable.

Business Process Improvement Methodologies like TQM, Kaizen, and PDCA help organizations achieve lasting success by fostering a culture of quality and continuous improvement.

Business Process Reengineering (BPR)

Strengths and Limitations

Business Process Reengineering (BPR) encourages organizations to rethink and redesign core processes. Teams often use BPR to achieve dramatic improvements in performance. BPR focuses on efficiency, cost reduction, and customer satisfaction. Many companies report significant gains after adopting BPR.

The main strengths of BPR include:

Large-scale efficiency improvements

Cost savings across departments

Enhanced transparency and adaptability

Faster problem resolution and time-to-market

Increased innovation and product quality

However, BPR also presents limitations. Teams may face resistance to change. The process often requires major shifts in culture and technology. Some organizations struggle with the complexity of redesigning entire workflows. BPR projects can demand significant resources and time.

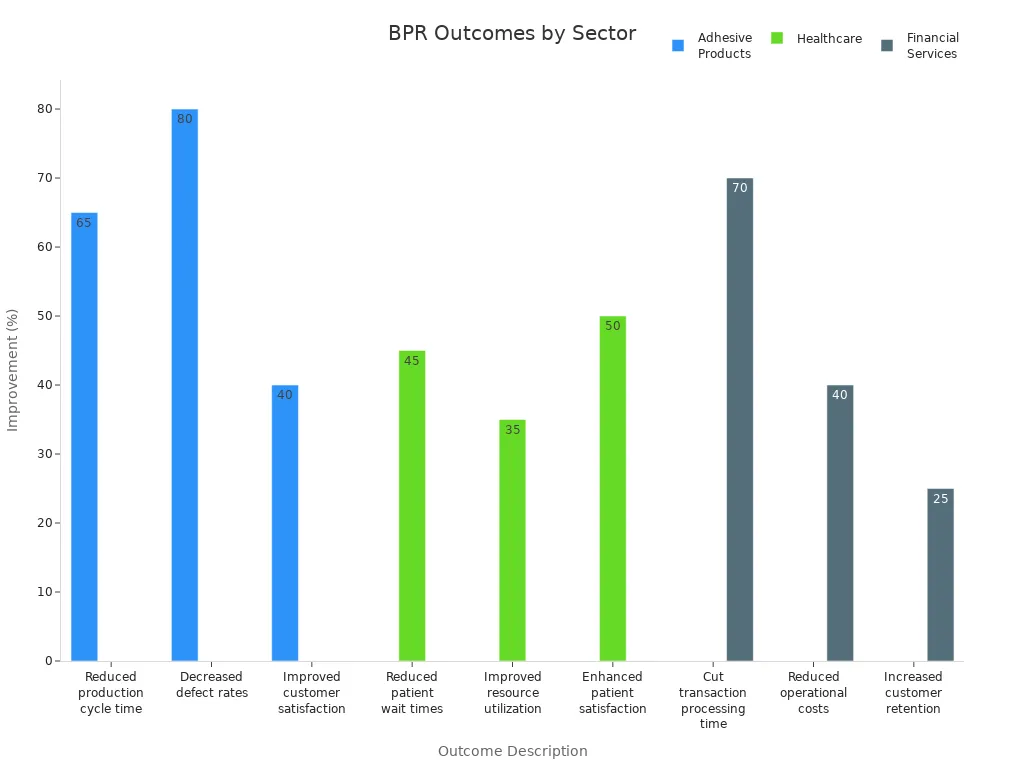

Sector | Outcome Description | Improvement Metrics |

|---|---|---|

Adhesive Products | Reduced production cycle time | |

Decreased defect rates | 80% reduction | |

Improved customer satisfaction scores | 40% increase | |

Healthcare | Reduced patient wait times | 45% reduction |

Improved resource utilization | 35% increase | |

Enhanced patient satisfaction ratings | 50% increase | |

Financial Services | Cut transaction processing time | 70% reduction |

Reduced operational costs | 40% reduction | |

Increased customer retention | 25% increase |

Teams that use BPR often see improved efficiency, reduced costs, and enhanced competitiveness. BPR helps organizations focus on core competencies and adapt quickly to market changes.

Ideal Use Cases

BPR works best for organizations seeking major transformation. Companies in manufacturing, healthcare, and financial services use BPR to overhaul outdated processes. BPR suits businesses that need to reduce cycle times, cut costs, and boost customer satisfaction. Teams aiming for faster time-to-market and higher product quality benefit from BPR. Many organizations choose BPR when incremental changes do not deliver the desired results.

Agile

Strengths and Limitations

Agile methodology supports rapid adaptation and continuous improvement. Teams break down projects into smaller tasks and complete them in short cycles. Agile encourages frequent feedback and iterative development. This approach helps organizations respond quickly to changing requirements.

Key strengths of Agile include:

Quick response to market shifts

Enhanced flexibility and adaptability

Faster delivery of value to customers

Continuous refinement based on feedback

Agile differs from traditional Business Process Improvement Methodologies. Traditional methods follow a linear process and often lack flexibility. Agile embraces change and allows teams to adjust plans as needed.

Agile's iterative approach enables organizations to deliver results faster and refine processes continuously.

Limitations of Agile may include challenges in scaling for large organizations. Some teams struggle with maintaining discipline and clear documentation. Agile requires strong collaboration and communication.

Ideal Use Cases

Agile fits organizations that operate in fast-paced environments. Software development teams use Agile to release updates quickly and respond to user feedback. Marketing and product teams benefit from Agile when they need to adapt campaigns or product features. Agile suits businesses that value flexibility and want to improve processes through ongoing iteration.

Agile helps organizations stay competitive by embracing change and delivering value rapidly. Teams seeking continuous improvement and adaptability often choose Agile over more rigid approaches.

Methodology Comparison

Key Differences

Business process improvement methodologies differ in their core focus, approach, and advantages. The following table highlights these distinctions:

Methodology | Core Focus | Best for | Key Advantages |

|---|---|---|---|

Lean Six Sigma | Speed and quality | Companies seeking efficiency and precision | Faster cycles, precise root-cause analysis |

Kaizen | Continuous, incremental improvement | Building a culture of improvement | Empowered teams, reduced resistance |

Total Quality Management (TQM) | Organization-wide commitment to quality | Aligning quality, culture, and performance | Customer focus, leadership commitment |

Agile BPM | Iterative, collaborative, adaptive | Digital teams, dynamic environments | Sprints, adaptability, feedback-driven |

Business Process Reengineering (BPR) | Radical redesign for breakthroughs | Processes needing major change | Transformational results |

PDCA | Iterative cycle for improvement | Systematic, ongoing improvements | Simple, universal, risk-minimizing |

Each methodology offers unique strengths. Lean Six Sigma combines speed with quality, while Kaizen builds a culture of ongoing improvement. TQM emphasizes organization-wide quality, and Agile BPM supports rapid adaptation. BPR enables radical change, and PDCA provides a simple, systematic approach.

When to Use Each

Organizations select methodologies based on their goals and challenges. The following scenarios illustrate effective use:

Lean Six Sigma suits companies that need both efficiency and precision. Teams use it for faster process improvement and detailed analysis.

Kaizen works best for organizations aiming to empower employees and foster continuous progress. It helps reduce resistance to change.

TQM fits enterprises that want to align quality with culture and performance. Leadership commitment drives success.

Agile BPM benefits digital teams and businesses in fast-changing markets. It breaks large changes into manageable sprints.

BPR serves organizations facing outdated or inefficient processes. It enables breakthrough improvements.

PDCA applies to any process needing systematic, ongoing improvement. Its simplicity makes it universal.

Case studies show that healthcare companies use BPR to streamline operations and improve profitability. Manufacturing firms apply process mining and automation to cut costs and reduce errors. Financial services teams automate account opening to boost engagement. Intergovernmental organizations redesign processes to achieve significant cost savings.

Limitations to Consider

Every methodology presents limitations that organizations must consider:

Kaizen may not suit companies needing rapid or radical transformation. Its incremental nature may not address major deficiencies.

Successful Kaizen requires a culture that values employee input and collaboration.

Lean Six Sigma demands significant management changes. Teams often need two years to adjust. Initial costs may rise due to extra resources or consultants.

Agile BPM can challenge large organizations that lack strong collaboration.

BPR requires substantial resources and may face resistance due to its radical approach.

PDCA depends on discipline; skipping steps can undermine results.

Tip: Organizations should assess their readiness for change and resource availability before selecting a methodology. Matching the approach to business needs increases the likelihood of success.

How to Select the Right Methodology

Assessing Needs and Goals

Organizations must start by understanding their needs and goals before choosing a process improvement approach. Leaders identify which processes drive the most value and where the biggest challenges exist. They look at suppliers, inputs, activities, outputs, customers, and metrics for each process. This helps them see the full picture.

A structured assessment helps teams focus on what matters most. The following table outlines a step-by-step approach:

Step | Description |

|---|---|

1 | Identify processes and their key components, including suppliers, inputs, activities, outputs, customers, and metrics. |

2 | Prioritize processes based on success criteria that align with organizational goals. |

3 | Develop a process prioritization matrix to rank processes according to their impact on strategic objectives. |

4 | List success criteria, weight them, and assign scores to processes to determine improvement priorities. |

Teams use these steps to match improvement efforts with business strategy. For example, a company that wants to improve customer satisfaction will focus on processes that affect the customer experience. A process prioritization matrix helps leaders decide where to start.

Tip: Clear goals and priorities make it easier to select the right methodology and measure success.

Evaluating Process Complexity

Process complexity plays a major role in selecting a methodology. Simple processes may only need basic tools, while complex systems require more structured approaches. Teams must look at how many steps a process has, how many people are involved, and how much variation exists.

A comparison of methodologies by complexity level can guide decision-making:

Methodology | Complexity Level | Description |

|---|---|---|

Six Sigma | High | A structured methodology for complex processes requiring comprehensive analysis and improvement. |

Business Process Reengineering | High | Focuses on redesigning processes for significant improvements in efficiency and quality. |

Kaizen | Low | A simpler approach aimed at continuous improvement in less complex processes. |

Lean | Low | Streamlines processes by eliminating waste, suitable for straightforward operations. |

For highly complex processes, organizations may use the Theory of Constraints. This approach targets the single biggest bottleneck in a system. Companies like XL.net have faced challenges with complex workflows. They used structured tools to simplify operations and improve results.

Note: Teams should match the complexity of their process with the structure of the methodology. Overly simple tools may not solve complex problems.

Considering Culture and Resources

Organizational culture and available resources shape the success of any improvement effort. Teams that value commitment, teamwork, and innovation adapt more easily to new methods. A culture of continuous improvement supports lasting change. Cross-functional collaboration and customer focus also help teams succeed.

Key cultural values that support process improvement include:

Commitment to change

Continuous improvement mindset

Cross-functional teamwork

Customer centricity

Innovation

Process ownership

Some organizations face resistance because of established norms and structures. Leaders must recognize these barriers and encourage a shift toward agility and adaptability. Without the right culture, even the best methodology may fail.

Resources also matter. Teams need time, training, and tools to implement new methods. Leaders must ensure they have enough support before starting a project.

Teams that align their culture and resources with their chosen methodology increase their chances of success.

Business Process Improvement Methodologies work best when organizations assess their needs, match the complexity of their processes, and build a supportive culture.

Using a Decision Matrix

A decision matrix helps organizations choose the best process improvement approach by providing a clear and structured way to compare options. Teams list possible Business Process Improvement Methodologies along one side of the matrix. They write important criteria, such as cost, training needs, speed, and fit with company culture, across the top. Each methodology receives a score for every criterion. The team adds up the scores to see which option fits their needs best.

A decision matrix offers several advantages:

It gives a structured framework for comparing different methods.

It reduces subjectivity and personal bias in decision-making.

It helps teams focus on what matters most for their organization.

It turns complex choices into a visual format that is easy to understand.

It supports better outcomes by making decisions based on facts.

Here is a simple example of a decision matrix for selecting a process improvement methodology:

Criteria | Lean | Six Sigma | Kaizen | Agile |

|---|---|---|---|---|

Cost | 4 | 2 | 5 | 3 |

Training Required | 5 | 2 | 4 | 3 |

Speed of Results | 4 | 3 | 3 | 5 |

Fit with Culture | 5 | 3 | 4 | 4 |

Total Score | 18 | 10 | 16 | 15 |

Tip: Teams can adjust the criteria and scoring system to match their unique needs.

To use a decision matrix, teams follow these steps:

List all possible methodologies.

Choose the most important criteria for the organization.

Score each methodology for every criterion.

Add the scores to find the best fit.

Review the results and discuss as a group.

A decision matrix helps teams make choices based on relevant factors. It also makes the process more objective and transparent. Leaders can see how each option aligns with their goals. This tool works well for both small and large organizations.

Business Process Improvement Methodologies become easier to select when teams use a decision matrix. The visual layout and scoring system help everyone understand the reasons behind the final choice.

Applying Business Process Improvement Methodologies

Planning and Preparation

Successful application of Business Process Improvement Methodologies begins with careful planning and preparation. Teams and systems must first identify what needs to change by conducting a process audit. They analyze pain points through process mapping, which helps everyone understand where issues exist. After pinpointing problems, teams make a process improvement plan that includes input from those involved. Stakeholders must support the plan, so teams work to get buy-in early. Estimating resource requirements ensures that the team has what it needs to move forward.

A clear plan sets the foundation for improvement. Teams define specific jobs, tasks, or processes targeted by the plan and set clear goals. Reviewing current work standards helps break down processes into fundamental steps, revealing weak points and inefficiencies. Teams redesign steps to eliminate these issues, using input from all members. Once the new process is ready, teams implement it into daily operations. Monitoring the new process with a timeline and key performance indicators (KPIs) helps measure success. Teams remain flexible, experimenting with different approaches and updating steps as needed.

Ordered List of Planning Steps:

Identify what needs to change with a process audit.

Analyze pain points using process mapping.

Create a process improvement plan with team input.

Get stakeholder buy-in for support.

Estimate resource requirements.

Define targeted jobs, tasks, or processes and set goals.

Review and analyze current work standards.

Redesign steps to remove inefficiencies.

Implement the new process.

Monitor results with KPIs and adjust as needed.

Building the Team

Building the right team is essential for process improvement. Systems and teams that include members from different departments enhance communication and collaboration. Cross-functional teams bring diverse perspectives, which improves problem-solving. These teams increase efficiency by reducing delays that often occur between departments. Greater business agility results from swift responses to challenges.

Collaboration breaks down information barriers, leading to better decision-making. Teams leverage unique strengths from each department, achieving more together than they could alone. Clients at systems and teams have seen streamlined processes and improved outcomes by forming cross-functional groups. This approach supports faster problem resolution and helps organizations adapt quickly.

Benefits of Cross-Functional Teams:

Enhanced communication and collaboration

Improved problem-solving capabilities

Increased efficiency

Greater business agility

Streamlined processes

Better decision-making

Training and Communication

Effective training and communication play a vital role in the success of process improvement projects. Teams must communicate the need for change to everyone affected. Clear communication keeps all stakeholders informed and aligned with project goals. A detailed communication management plan helps streamline information sharing.

Open communication encourages employees to share suggestions for improvement. Collaboration fosters teamwork and shared ownership. Recognizing contributions boosts employee engagement, which is vital for successful process improvements. Systems and teams that prioritize training and communication see higher engagement and smoother implementation.

Table: Training and Communication Best Practices

Practice | Impact |

|---|---|

Clear communication of changes | Keeps stakeholders informed and aligned |

Open feedback channels | Encourages suggestions and collaboration |

Recognition of contributions | Boosts engagement and ownership |

Detailed communication plan | Streamlines information sharing |

Teams that focus on training and communication build trust and support for new processes. This approach helps sustain improvements over time.

Implementation Steps

Organizations achieve successful process improvement by following a series of structured steps. These steps guide teams from analysis to execution, ensuring that changes deliver measurable results. The process begins with a thorough examination of current workflows. Teams analyze each step to identify inefficiencies and bottlenecks. They gather feedback from stakeholders, including employees and managers who interact with the process daily. This feedback provides valuable insights and highlights areas for improvement.

Setting clear goals and objectives comes next. Teams use the SMART criteria—Specific, Measurable, Achievable, Relevant, and Time-bound—to define what success looks like. These goals keep everyone focused and motivated throughout the project. After establishing objectives, teams develop improvement strategies. They brainstorm solutions that address the identified problems and select the most effective approaches.

Implementation involves executing the chosen strategies. Teams introduce changes in a controlled manner, often starting with pilot programs or small-scale tests. They monitor progress closely, tracking key metrics to ensure that improvements deliver the expected benefits. Regular check-ins help teams adjust strategies as needed and maintain momentum.

Recommended Implementation Steps:

Analyze current processes to find inefficiencies.

Gather feedback from stakeholders for deeper insights.

Set goals and objectives using SMART criteria.

Develop strategies to address improvement opportunities.

Implement and monitor improvement initiatives.

Tip: Teams should document each step and communicate progress to all stakeholders. Clear documentation supports transparency and helps sustain improvements over time.

Monitoring and Measuring Success

Measuring the success of process improvement initiatives requires careful selection of metrics. Teams use key performance indicators (KPIs) to track progress and evaluate outcomes. Common metrics include cycle time, defect rate, first pass yield, capacity utilization, and cost per unit. These indicators provide a clear picture of how changes impact efficiency and quality.

Cycle time measures the total time needed to complete a process from start to finish. Yield rate shows the number of compliant products produced compared to resources used. Cost per unit produced helps organizations understand the financial impact of improvements. Return on investment (ROI) compares the benefits gained to the costs incurred during the project.

Metric | Description |

|---|---|

Cycle time | Time required to complete a process |

Yield rate | Ratio of compliant products to total resources used |

Cost per unit | Total production cost divided by units produced |

Defect rate | Percentage of products with errors or defects |

Capacity utilization | Percentage of available capacity used |

ROI | Benefits compared to project costs |

Teams review these metrics regularly to ensure that improvements remain effective. They adjust processes when results fall short of expectations. Continuous monitoring helps organizations sustain gains and identify new opportunities for optimization.

Note: Consistent measurement and review support long-term success with Business Process Improvement Methodologies.

Case Studies

Success Stories

Many organizations have achieved remarkable results by applying business process improvement methodologies. These companies faced different challenges and used structured approaches to redesign their processes. The following table highlights several notable examples:

Organization | Challenge | Redesign Steps | Key Outcomes |

|---|---|---|---|

Major Multinational Engineering Company | Needed a standardized global HR operating model | Eliminated redundant FAQs, standardized service levels, optimized helpdesk loads, automated support | Launched a unified global HR helpdesk, improved efficiency, enhanced employee experience, rapid platform rollout |

Fortune 500 Engineering/Architecture Company | Cumbersome manual timesheet process | Eliminated manual forms, standardized forms, optimized ERP, automated timesheet reporting | Reduced processing time from over four days to two days, saved 723 hours annually |

Global IT Company | Complex legacy sales compensation system | Consolidated applications, standardized processes, automated reconciliation | Integrated platform for real-time sales data access, reduced turnaround times, increased data accuracy |

Global Consumer Brands Company | Ineffective Order-to-Cash processes | Removed stages from order management, standardized discounting, optimized claims process | Improved effectiveness and efficiency in O2C processes in South-East Asia region |

These organizations improved efficiency and accuracy by standardizing and automating their processes. They reduced manual work and increased employee satisfaction. Teams launched new platforms quickly and saved hundreds of hours each year. Companies also saw better data accuracy and faster turnaround times. These results show that a structured approach to process improvement can deliver measurable benefits.

Tip: Standardization and automation often lead to faster results and higher quality outcomes.

Lessons Learned

Not every process improvement project succeeds on the first attempt. Teams have learned important lessons from failed or challenging efforts. The following points summarize key insights:

Automating a broken or non-standardized process creates bigger problems instead of solutions.

Teams should clean up and standardize processes before starting automation.

Ownership of the process must belong to the business, not just IT or outside vendors.

Defining success only by delivery, rather than performance, can cause major issues.

Lack of end-to-end simulations leads to data inconsistencies across systems.

Effective governance requires ownership that crosses functional boundaries.

End-to-end process management means validating each step under real-world conditions.

Small misalignments can build up over time and result in project failure.

Teams that follow these lessons increase their chances of success. They focus on standardization, clear ownership, and thorough testing. Organizations also benefit from strong governance and real-world validation. These practices help avoid common pitfalls and support lasting improvements.

Note: Careful planning and attention to detail help organizations avoid costly mistakes in process improvement projects.

Selecting and applying the right business process improvement methodology shapes long-term business success. Teams that use structured approaches streamline workflows, reduce costs, and deliver greater value to customers. Continuous improvement helps organizations adapt, minimize waste, and boost morale.

Enhanced efficiency and effectiveness

Streamlined communication and data flow

Early risk identification

Improved quality and customer loyalty

Leaders should assess their processes and take action. For those seeking deeper insights, reaching out for expert guidance can accelerate results.

FAQ

What are Business Process Improvement Methodologies?

Business Process Improvement Methodologies are structured approaches that help organizations analyze and improve their workflows. These methods aim to increase efficiency, reduce waste, and improve quality in business operations.

How does a company choose the right methodology?

A company should assess its goals, process complexity, culture, and available resources. Using a decision matrix can help compare different Business Process Improvement Methodologies and select the best fit for the organization.

Can small businesses use Business Process Improvement Methodologies?

Yes, small businesses can benefit from these methodologies. They can start with simple approaches like Kaizen or PDCA to make gradual improvements without needing large investments.

How long does it take to see results?

The time to see results depends on the chosen methodology and the size of the project. Some improvements show benefits in weeks, while others may take several months to deliver noticeable changes.

What are common mistakes when applying these methodologies?

Common mistakes include skipping planning steps, not involving key team members, and failing to measure results. Companies should also avoid choosing a methodology that does not match their needs.

Do employees need special training?

Most Business Process Improvement Methodologies require some training. Teams should learn the basics of the chosen approach to ensure everyone understands the steps and goals.

How can success be measured?

Success can be measured using key performance indicators like cycle time, defect rate, and cost per unit. Regular monitoring helps teams track progress and make adjustments as needed.

Can these methodologies work in non-manufacturing industries?

Yes, Business Process Improvement Methodologies apply to many industries, including healthcare, finance, and services. They help organizations improve processes, reduce errors, and deliver better customer experiences.