How to Identify and Fix Inefficiencies in Your Business Processes

Imagine a team struggling to meet deadlines despite hard work. The answer often lies in how they use their systems and resources. Structured business processes, especially those with room for exceptions, help organizations adapt and succeed. Studies show that nearly 60% of business activities follow a semi-structured methodology, balancing predictability with flexibility. Spotting inefficiencies requires a clear look at each step and a willingness to adjust what does not work.

Key Takeaways

Identify inefficiencies by looking for missed deadlines, poor communication, and repetitive tasks.

Use process mapping to visualize workflows and spot unnecessary steps or bottlenecks.

Gather data on key metrics like cycle time and error rate to measure process performance.

Involve stakeholders in identifying inefficiencies to gain valuable insights and improve accuracy.

Automate repetitive tasks to save time and allow employees to focus on more strategic work.

Standardize processes with clear operating procedures to ensure consistency and reduce errors.

Foster a culture of continuous improvement by encouraging employee feedback and innovation.

Regularly review and adjust processes to maintain efficiency and adapt to changing business needs.

Signs of Inefficiency

Common Indicators

Many organizations notice inefficiencies through clear warning signs. Industry experts often point to these common indicators:

Inefficient communication and siloed teams

Repetitive tasks and manual data entry

High employee turnover

Rising costs

These issues can appear in any department. Missed deadlines signal that teams struggle to keep up with demand. Inefficient communication leads to confusion and duplicated work. Manual data entry and repetitive tasks waste valuable time. High turnover suggests employees feel frustrated or unsupported. Rising costs often reflect wasted resources or outdated methods.

These signs indicate inefficiencies that can lead to lost opportunities, decreased employee morale, and increased operational costs, ultimately affecting the competitiveness and profitability of the business.

Impact on Results

Inefficiencies in business processes do not just slow down daily work. They can have a direct impact on results. Several real-world examples show how these problems affect organizations:

A transportation equipment manufacturer faced a 25% decrease in supply chain efficiency, which led to operational disruptions and higher costs.

A plastics manufacturing company experienced a 20% increase in operational costs and a 15% decrease in market share due to outdated processes.

A retailer saw a 20% decline in in-store sales because of supply chain issues and a lack of digital marketing strategies.

A robotics startup in healthcare reported a 20% rise in operational costs, which hurt its market position.

A consulting firm specializing in digital transformation observed a 20% drop in new client acquisitions due to internal inefficiencies in sales operations.

These examples highlight how inefficiencies can reduce profits, limit growth, and damage a company’s reputation.

Frustration Points

Employees often feel the effects of inefficient business processes in their daily routines. The most frequently reported frustration points include:

Frustration Point | Description |

|---|---|

Manual processes | Tedious tasks that can lead to wasted time and increased risk of human errors. |

Working in silos | Redundant tasks due to lack of communication, leading to wasted work hours. |

Poor reporting | Inefficient data reporting makes it hard to evaluate project success and can increase operating costs. |

Physical processes | Reliance on paper forms leads to wasted administrative work that could be digitized. |

Outdated tools | Using old software and systems causes frustration and inefficiencies in work processes. |

Other common complaints include ineffective communication, which leads to misunderstandings and duplicated work, and slow decision-making processes, often caused by micromanagement. These frustration points not only lower morale but also make it harder for teams to achieve their goals.

Understanding Business Processes

Definition

Experts define business processes as structured activities that organizations use to deliver products or services efficiently. These activities focus on maximizing output and reducing wasted resources like time, money, and effort. Operational efficiency depends on how well a company organizes its workflows and improves productivity. Streamlining business processes helps teams minimize waste and use resources wisely. Companies that focus on continuous improvement often see better performance and higher customer satisfaction.

Tip: Clear business processes make it easier for teams to understand their roles and responsibilities, which leads to fewer mistakes and faster results.

Key Stages

Business processes follow several important stages. Each stage plays a role in improving efficiency and reaching organizational goals. The table below outlines these stages and their descriptions:

Stage | Description |

|---|---|

Design | Understanding current processes and developing an improvement plan based on identified goals. |

Model | Creating models of the analyzed business processes. |

Execute | Implementing the planned business processes into action. |

Monitor | Establishing metrics and KPIs to track the effectiveness of the processes. |

Optimize | Continuously improving the documented and analyzed business processes. |

Teams use these stages to review and adjust their workflows. They design new methods, model possible changes, and execute plans. Monitoring helps leaders track progress, while optimization ensures ongoing improvement.

Types of Business Processes

Organizations rely on different types of business processes to operate smoothly. Each type faces unique efficiency challenges. The table below explains the main types and their differences:

Type of Process | Description | Efficiency Challenges |

|---|---|---|

Core processes | Directly deliver value to customers, such as client onboarding and support. | Any breakdown can impact customer satisfaction and revenue, requiring optimization. |

Support processes | Enable core operations, including HR and IT support. | Inefficiencies can stall core processes, necessitating streamlining and automation. |

Management processes | Provide oversight and direction, including strategic planning and budgeting. | Lack of visibility can hinder decision-making and alignment with organizational goals. |

Core processes affect customers directly. Support processes help core activities run smoothly. Management processes guide the company and set its direction. Each type needs regular review to avoid inefficiencies and keep the organization moving forward.

Business processes shape how companies deliver value and achieve their goals. Understanding the definition, stages, and types helps leaders spot areas for improvement and build stronger systems.

Identify Inefficiencies

Identifying inefficiencies in business processes requires a structured approach. Teams can use mapping, data collection, and bottleneck analysis to uncover hidden problems. Each step helps organizations find areas for improvement and make informed decisions.

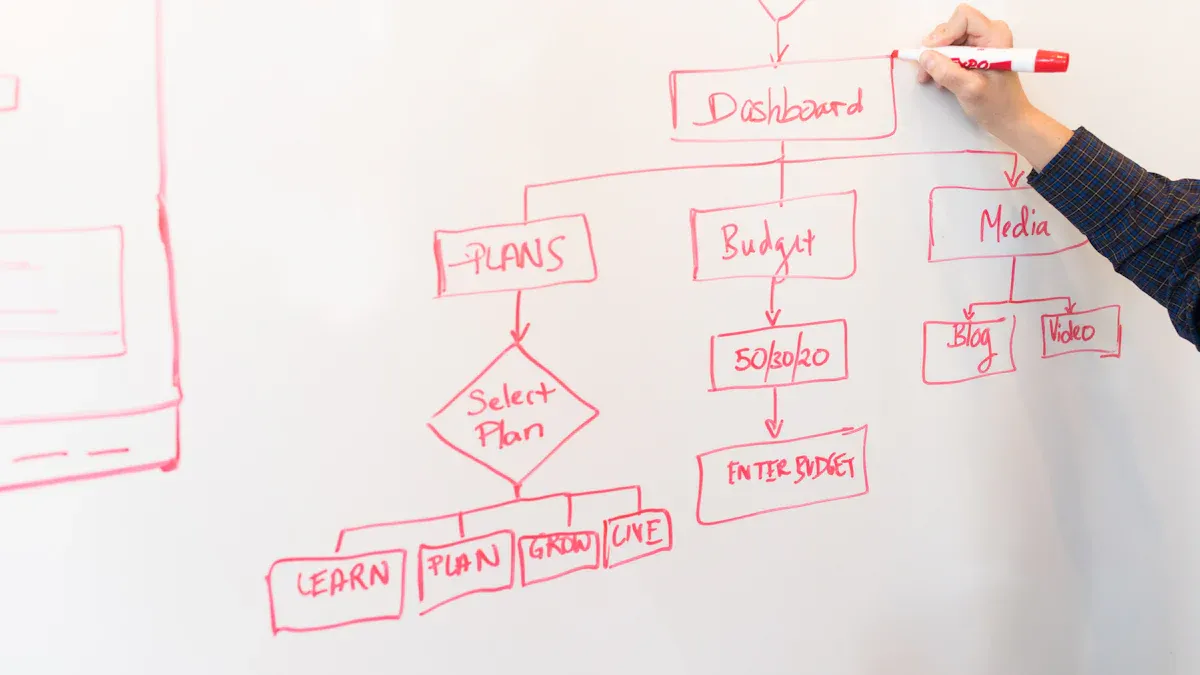

Map Processes

Mapping processes gives a clear view of how work flows through an organization. Teams can spot unnecessary steps, unclear responsibilities, and areas where tasks slow down. Different mapping methods serve different purposes.

Tools

The table below shows common types of process maps, their purposes, and when to use them:

Type of Process Map | Purpose | Best For |

|---|---|---|

Flowchart | Shows inputs, outputs, and steps from start to finish. | Documenting processes during onboarding or brainstorming. |

High-level process map | Provides a bird’s-eye view of a process, focusing on key phases. | Communicating essential steps without details. |

Detailed process map | Includes all actions, decisions, and metrics for thorough analysis. | Analyzing complex workflows and finding inefficiencies. |

Swimlane map | Organizes processes by separating responsibilities into lanes. | Clarifying roles in multi-team processes. |

Value stream map | Tracks the journey of a product/service from start to delivery. | Finding opportunities to reduce waste. |

SIPOC diagram | High-level view of a workflow before detailed mapping. | Outlining components before full workflow mapping. |

BPMN | Standardized method for business process mapping. | Effective communication of business processes. |

Tip: Start with a high-level map to understand the big picture, then use detailed maps to find specific inefficiencies.

Stakeholders

Involving stakeholders ensures accuracy and completeness. Stakeholders include team members who perform the tasks, managers who oversee the process, and customers who receive the output. Their insights help identify steps that add value and those that cause delays. Teams should invite stakeholders to workshops or mapping sessions to gather different perspectives.

Gather Data

Collecting data helps teams measure how well processes perform. Data shows where delays, errors, or waste occur. Using both numbers and opinions gives a full picture.

Metrics

Key metrics help organizations track efficiency and spot problems. The table below lists common metrics and their uses:

Metric | Description | Example |

|---|---|---|

Cycle Time | Measures the total duration it takes for a process to run from beginning to end. | Time from order placement to delivery in an e-commerce operation. |

Error Rate | Captures the frequency of defects, mistakes, or failures within a process. | Percentage of payroll runs that contain calculation errors. |

Throughput | Quantifies the volume of output a process generates within a given timeframe. | Number of support tickets resolved per agent per day. |

First Pass Yield | Indicates the percentage of work completed correctly without needing rework. | Ratio of manufactured items that pass inspection on the first attempt. |

Teams should choose metrics that match their goals. For example, a support team may focus on throughput, while a manufacturing team may track error rates.

Feedback

Feedback from stakeholders adds context to the numbers. Teams can use several methods to gather feedback:

Surveys

Focus groups

Direct observations

Suggestion boxes

Regular check-ins

Automated tracking

AI-driven analytics

Regular feedback helps teams find hidden issues and encourages innovation. Internal feedback often comes from informal channels, while external feedback may require formal surveys.

The table below shows types of data organizations can collect:

Data Type | Description |

|---|---|

First-party data | Collected directly from users by your organization. |

Second-party data | Shared by another organization about its customers. |

Third-party data | Aggregated data rented or sold by organizations without a direct connection. |

Qualitative data | Contextual data focusing on opinions, motivations, and behaviors. |

Quantitative data | Numeric data ideal for statistical analysis. |

Find Bottlenecks

Bottlenecks slow down business processes and reduce efficiency. Teams must find and address these problem areas to improve performance.

Flow Visualization

Visualizing workflows helps teams spot bottlenecks quickly. Best practices include:

Real-time visualization with heat maps and flow charts

Data collection from equipment and sensors for up-to-date information

Creating visual maps and overlaying real-time data

Using heat maps to show performance with color gradients

Monitoring Kanban boards to see where work piles up

Displaying real-time dashboards for overall system performance

Tracking flow rates to find where throughput drops

Workflow visualization highlights slow points and helps teams focus their improvement efforts.

Repetitive Tasks

Repetitive tasks often cause inefficiency. Automating these tasks allows employees to focus on creative and strategic work. Research shows that 42% of business leaders see time savings from automation, and 85% believe it helps employees concentrate on strategic goals. Most knowledge workers feel less stressed when they automate repetitive tasks, which leads to more meaningful work and better results.

Outdated systems

Manual processes

Inefficient workflows

Resource allocation issues

Teams can identify these bottlenecks by:

Mapping workflows to find slow points

Analyzing performance data

Gathering employee insights

Note: Involving stakeholders in bottleneck analysis ensures that teams do not overlook important details.

By mapping processes, collecting data, and analyzing bottlenecks, organizations can uncover inefficiencies and take steps to improve their business processes.

Analyze Root Causes

Identifying inefficiencies is only the first step. Teams must dig deeper to understand why these problems occur. Root cause analysis helps organizations address the real issues, not just the symptoms. Three proven methods—5 Whys, Fishbone Diagram, and direct observation—can reveal the underlying causes of process breakdowns.

5 Whys

The 5 Whys technique encourages teams to ask "why" multiple times until they reach the root cause of a problem. This method works well for recurring issues that seem to resist quick fixes. By moving beyond surface-level symptoms, teams can create lasting solutions.

The 5 Whys technique helps teams identify the root cause of recurring issues, not just the symptoms.

It encourages deeper investigation into process failures, leading to sustainable improvements.

By fostering critical thinking and collaboration, it helps avoid quick fixes that do not resolve the actual problem.

For example, if a team misses deadlines, they might ask why the delay happened. Each answer leads to another "why," eventually uncovering the true source of the problem, such as unclear task assignments or outdated tools.

Tip: Teams should document each "why" and involve people closest to the process for the most accurate results.

Fishbone Diagram

The Fishbone Diagram, also known as the Ishikawa or cause-and-effect diagram, provides a visual way to organize possible causes of a problem. This tool helps teams break down complex issues into manageable categories.

Identify the defect and place it at the top of the fishbone as the 'effect.'

Draw a horizontal arrow to the right for the main section of the fishbone.

Group major causes into categories like Personnel, Technology, Processes, etc.

List factors for each category using 'why does this occur' to explore root causes.

Repeat the 'why' question for each cause to uncover deeper factors.

Analyze the diagram for patterns and areas needing improvement.

Teams often use the Fishbone Diagram during group sessions. This approach encourages everyone to share ideas and spot patterns that may not be obvious at first glance.

Note: Using categories like People, Methods, Machines, and Materials helps teams cover all possible sources of inefficiency.

Observation

Direct observation allows teams to see business processes in action. Watching workflows firsthand reveals details that data alone may miss. Teams can notice how people interact, how tools are used, and where delays happen.

Direct observation allows teams to see processes in action, revealing factors that data alone may miss.

It helps in understanding the nuances of workflows, interactions, and environmental conditions.

Engaging with frontline workers during observation provides insights into issues and improvement opportunities that may not be immediately apparent.

For instance, a manufacturing facility might analyze production data and find an assembly line underperforming. By directly observing the line, the team could discover ergonomic issues or material flow bottlenecks. This approach prevents decisions based on incomplete information and leads to more effective solutions.

The main goal of direct observation is to identify opportunities for process improvements and waste reduction. By witnessing processes firsthand, teams can accurately pinpoint the root causes of inefficiencies and bottlenecks that might be overlooked through traditional reporting methods.

Teams should always involve frontline employees during observation to gain practical insights and build trust.

Fix Inefficiencies

Improving business processes requires a focused approach. Organizations can redesign steps, automate tasks, and standardize procedures to achieve lasting efficiency. Systems and teams that follow these strategies often see measurable improvements in productivity and quality.

Redesign Steps

Redesigning process steps helps organizations remove obstacles and create smoother workflows. Successful systems and teams use a structured method to achieve this.

Streamline

Streamlining involves simplifying tasks and eliminating unnecessary steps. Teams start by defining current processes and analyzing their effectiveness. They develop solutions, such as removing redundant actions or introducing new technology. Clear goals and process metrics guide the redesign. Teams implement changes with proper training and resources. Monitoring results ensures the redesign delivers expected improvements. Agile practices allow quick adaptation to changing needs.

Tip: Teams should reassess and refine processes regularly to maintain optimal performance.

Remove Waste

Removing waste means identifying activities that do not add value. Teams look for bottlenecks, delays, and repetitive tasks. They focus on eliminating manual work and reducing errors. Systems and teams that adopt waste reduction strategies often see lower costs and faster results.

Steps to remove waste:

Map the workflow to spot non-value-adding activities.

Collect data on time spent and errors.

Involve stakeholders to identify pain points.

Implement solutions such as automation or process changes.

Monitor and adjust to ensure waste stays low.

Automate Tasks

Automation transforms manual processes into efficient, technology-driven workflows. Systems and teams that automate tasks report significant gains in speed and accuracy.

Tool Selection

Choosing the right automation tools is critical. Teams evaluate process characteristics, business value, and technical feasibility. They consider implementation factors, high volume, and manual actions. Standardized, rule-based steps are easier to automate. Teams also assess digital input, measurable impact, time savings, error reduction, cost efficiency, customer impact, system integration, data quality, security, support resources, stakeholder support, resource availability, timeline alignment, and risk level.

Criteria | Description |

|---|---|

Process characteristics | Evaluate the fundamental nature of the process to determine its suitability for automation. |

Business value | Assess the potential impact and benefits that automation could bring to the organization. |

Technical feasibility | Analyze the technical requirements and ensure the process can be effectively automated. |

Implementation factors and risks | Consider practical aspects for implementation, such as resources, timelines, and training. |

High volume | Processes that occur frequently or handle large volumes of data are prime candidates for automation. |

Manual and repetitive actions | Tasks that are currently manual and repetitive are strong contenders for automation. |

Standardization | Highly standardized processes with minimal variations are best for automation. |

Rule-based steps | Processes governed by clear rules are easier to automate than those requiring nuanced decision-making. |

Digital input | Processes reliant on unstructured data are more challenging to automate. |

Measurable impact | The process must have defined start and end points, along with measurable outcomes. |

Time savings | Automation can save significant manual hours. |

Error reduction | Automation reduces the risk of human error by executing tasks with consistent accuracy. |

Cost efficiency | The costs of automation must be justified by long-term savings. |

Customer impact | Automation efforts should positively impact customer satisfaction. |

System integration | Evaluate if the software apps involved offer suitable APIs or integration points. |

Data quality | Automation works best with consistent and high-quality input data. |

Security and compliance | Ensure automation initiatives meet security and compliance requirements. |

Support resources | Technical expertise may be needed depending on the complexity of the process. |

Stakeholder support | Alignment and support from all relevant stakeholders are essential for success. |

Resource availability | Sufficient resources, including budget and personnel, must be available for automation. |

Timeline alignment | The implementation timeline should align with current business priorities. |

Risk level | Risks associated with automation should be manageable with clear mitigation strategies. |

Teams at systems and teams have successfully automated onboarding, customer management, marketing, IT support, and purchase orders. These improvements reduce paperwork, speed up approvals, and enhance customer satisfaction.

Training

Training ensures employees can use new automation tools effectively. Companies that invest in training report faster processing times and higher innovation. Training helps team members understand their roles and responsibilities, which increases transparency. Organizations that provide automation training see higher employee retention and productivity.

A McKinsey Global Institute study found that 60% of occupations could automate 30% or more of their activities.

Companies with automation training reduced processing times by 50%.

Teams at systems and teams experienced faster time-to-market and increased innovation after training.

BPM training helps teams increase ROI and understand process changes.

Note: Training supports successful adoption and helps teams adjust to new workflows.

Standardize Processes

Standardization creates consistency and improves quality across business processes. Systems and teams that standardize procedures achieve better results and easier compliance.

SOPs

Standard operating procedures (SOPs) guide employees through tasks step by step. SOPs minimize errors and streamline workflows. They reduce variability and ensure everyone follows the same process. SOPs also serve as training manuals, helping new employees learn quickly.

SOPs lead to consistent outcomes and fewer mistakes.

Teams use SOPs to eliminate wasted time and resources.

SOPs support onboarding and ongoing training.

Consistency

Consistency ensures high-quality results and customer satisfaction. Standardized processes make it easier to monitor KPIs and improve workflows. Organizations benefit from cost savings, waste reduction, and competitive advantage.

Benefit | Description |

|---|---|

Consistency and quality control | Ensures processes are carried out consistently, leading to high-quality results and customer satisfaction. |

Improved efficiency and productivity | Streamlining processes reduces wasted time and resources, enhancing overall productivity. |

Enhanced training and onboarding | Simplifies training by reducing redundancies, allowing quicker employee onboarding. |

Facilitated process analysis and improvement | Makes it easier to monitor KPIs and improve processes, ensuring compliance with regulations. |

Cost Savings and Waste Reduction | Optimizes processes to eliminate inefficiencies, leading to cost savings and better resource utilization. |

Competitive Advantage | Provides a significant edge by delivering consistent quality and reducing costs, attracting customers. |

Teams at systems and teams have used standardization to meet regulatory guidelines and embed compliance into daily operations. This approach supports process analysis and continuous improvement.

Tip: Regularly review and update SOPs to maintain consistency and adapt to new requirements.

By redesigning steps, automating tasks, and standardizing processes, organizations can fix inefficiencies and build stronger systems and teams. These strategies help companies achieve better results and stay competitive.

Best Practices

Monitor Continuously

Continuous monitoring helps organizations maintain efficient business processes. Teams track progress and identify areas for improvement. Leaders set clear goals and define key performance indicators (KPIs) that align with business objectives. They use feedback loops and the PDCA (Plan-Do-Check-Act) cycle to guide systematic enhancements. Training and stakeholder engagement support successful adoption of new practices.

Best Practice | Description |

|---|---|

Setting Clear Goals and KPIs | Align monitoring goals with business objectives and define SMART KPIs for effective tracking. |

Continuous Improvement and Feedback Loops | Foster a culture of continuous improvement and utilize the PDCA cycle for systematic enhancements. |

Training and Engaging Stakeholders | Provide comprehensive training and support to ensure stakeholder engagement and successful adoption. |

Tip: Teams should review process data regularly and adjust strategies to stay on track.

Foster Improvement

A culture of continuous improvement drives long-term efficiency. Employees share ideas and suggest changes. Leaders encourage open communication and reward innovation. Teams identify inefficiencies and work together to solve problems. This approach leads to several benefits:

Increased efficiency and productivity: Streamlined processes help teams work faster.

Cost reduction: Eliminating waste saves money and resources.

Improved quality and customer satisfaction: Better processes meet customer needs.

Employee engagement and motivation: Empowered employees feel valued and motivated.

Competitive advantage and business growth: Innovation and adaptability support growth.

Organizations that foster improvement see lasting results. They adapt quickly to changes and maintain high standards.

Note: Regular team meetings and suggestion programs help keep improvement efforts active.

Set KPIs

Key performance indicators (KPIs) measure the success of business processes. Leaders select KPIs that reflect important goals. Teams track these metrics to evaluate efficiency and quality. Common KPIs include:

Quality: Measures if the output meets client standards.

Error rate: Counts the number of failures in the process.

Customer satisfaction: Assesses how well the process meets customer expectations.

Conversion rate: Tracks the number of prospects converted to customers.

Competitiveness: Evaluates market share against competitors.

Profitability: Analyzes the relationship between revenue and costs.

Teams use KPIs to guide decision-making and focus improvement efforts. Regular reviews help organizations stay competitive and achieve their objectives.

Teams should update KPIs as business needs change to ensure ongoing relevance.

Avoid Pitfalls

Improving business processes can bring many benefits, but organizations often face common pitfalls that slow progress or even cause failure. Recognizing these challenges helps teams avoid mistakes and achieve better results.

Overcomplication

Many organizations fall into the trap of making processes more complex than necessary. Overcomplicating tasks reduces productivity and wastes valuable resources. Employees may feel overwhelmed by too many steps or unclear instructions. This complexity often leads to stress and burnout. Teams may also use jargon in meetings, which can discourage open discussion and limit engagement. When processes become too complicated, employees may feel dissatisfied and less willing to collaborate.

Overcomplicated workflows waste time and energy.

Employees experience higher stress and risk burnout.

Jargon and complex language can exclude team members from important conversations.

Complexity can create a sense of exclusivity, making some employees feel left out.

Tip: Teams should focus on simplicity. Clear, straightforward processes help everyone understand their roles and responsibilities.

Ignoring Input

Successful process improvement depends on input from everyone involved. When organizations ignore feedback from employees or stakeholders, they miss valuable insights. Lack of communication can lead to disengagement and stalled projects. Employees may feel disconnected if they do not know about changes or cannot share their ideas. Not involving the right people limits understanding of complex workflows and can result in poor decisions.

Employees who feel ignored may lose motivation.

Projects can stall without open communication.

Teams may overlook important details if they do not gather input from all stakeholders.

Organizations should encourage regular feedback and involve team members in every stage of process improvement. Open communication builds trust and leads to better solutions.

Skipping Measurement

Measurement is essential for tracking progress and making informed decisions. Some organizations skip this step, relying on assumptions instead of data. Poor data or lack of research can damage the validity of process improvement efforts. Without clear metrics, teams cannot see what works or where problems remain. Ignoring technology advancements can also leave organizations behind in a rapidly changing landscape.

Lack of measurement makes it hard to track success.

Teams may waste resources on ineffective changes.

Organizations risk falling behind if they ignore new tools and methods.

Note: Teams should set clear goals and use data to measure results. Regular measurement helps organizations adapt and improve over time.

By avoiding these pitfalls—overcomplication, ignoring input, and skipping measurement—organizations can create efficient, effective business processes that support long-term success.

Teams can improve business processes by following clear steps: identify weak areas, analyze causes, design solutions, implement changes, and monitor results. Employee involvement and open communication help spot problems early. Continuous monitoring ensures improvements last. Every organization benefits from regular evaluation and action. For those seeking expert guidance, reaching out to systems and teams can provide valuable support on the journey to greater efficiency.

FAQ

What is the first step to identify inefficiencies in a business process?

Teams should start by mapping out each step of the process. This visual approach helps everyone see where delays or confusion happen. Process maps make it easier to spot unnecessary steps or bottlenecks.

How often should organizations review their business processes?

Experts recommend reviewing processes at least once a year. Regular reviews help teams catch new inefficiencies early. Fast-growing companies may benefit from more frequent checks.

Which tools help visualize business processes?

Teams often use flowcharts, swimlane diagrams, and value stream maps. These tools show how tasks move from start to finish. Software like Lucidchart or Microsoft Visio can make mapping easier.

Why is employee feedback important in process improvement?

Employee feedback gives real-world insights. Workers know where problems occur because they use the processes daily. Their suggestions often lead to practical solutions and better team engagement.

What are common causes of process bottlenecks?

Bottlenecks often result from outdated systems, manual tasks, or unclear responsibilities. Poor communication and lack of resources also slow down workflows. Teams should look for these issues during analysis.

How does automation improve efficiency?

Automation reduces manual work and errors. It speeds up repetitive tasks and allows employees to focus on higher-value activities. Many organizations see faster results and lower costs after automating key steps.

What is the role of KPIs in process improvement?

KPIs, or key performance indicators, measure how well a process works. Teams use KPIs to track progress and set goals. Clear KPIs help leaders make informed decisions and drive continuous improvement.

Can small businesses benefit from process improvement?

Yes. Small businesses often see quick results from even minor changes. Streamlined processes save time and money. Improved efficiency helps small teams compete with larger organizations.