5 Steps to Implement Business Process Improvement Methodologies

Organizations utilizing business process improvement methodologies often experience faster task completion, lower costs, and enhanced quality. Many teams report a 40-60% reduction in task completion time and a 25-30% decrease in operational costs. Systems designed around methodologies such as Six Sigma, Lean, TQM, Kaizen, PDCA, and BPR contribute to reducing errors and defects by 50%. Leaders should consider available resources and assess their readiness before implementing any methodology. The following table illustrates typical results:

Metric | Improvement Percentage |

|---|---|

Task completion time reduction | 40-60% |

Reduction in operational costs | 25-30% |

Reduction in errors and defects | 50% |

Increase in customer satisfaction | 30% |

Decrease in customer complaints | up to 45% |

Return on investment | 150-200% within first year |

Key Takeaways

Business process improvement can lead to faster task completion and lower costs.

Selecting the right methodology, like Lean or Six Sigma, depends on organizational goals and culture.

Engaging employees in improvement efforts fosters a culture of continuous enhancement.

Mapping workflows helps identify inefficiencies and areas for improvement.

Setting measurable goals aligns process improvements with business strategy.

Regular monitoring of progress ensures that changes deliver expected results.

Leadership support is crucial for embedding changes and scaling success.

Using data-driven approaches helps teams make informed decisions and optimize processes.

Business Process Improvement Methodologies

Business Process Improvement Methodologies help organizations achieve better results by focusing on efficiency, quality, and waste reduction. Each methodology offers a unique approach to solving problems and improving workflows. Teams often select a methodology based on their goals and operational needs.

Common Approaches

Six Sigma

Six Sigma provides a framework to maximize process quality by minimizing defects and reducing variability. Teams use data-driven steps: Define, Measure, Analyze, Improve, and Control. This approach focuses on process improvement and quality control. Six Sigma suits organizations that want to reduce errors and improve consistency.

Lean

Lean aims to minimize waste and maximize value. Teams identify value, map value streams, create flow, establish pull, and pursue continuous improvement. Lean works well for organizations that want to streamline operations and eliminate unnecessary steps. The main goal is to deliver more value to customers with fewer resources.

TQM

Total Quality Management (TQM) centers on customer satisfaction and continual improvement. This system encourages total employee involvement and a process-centered approach. TQM helps organizations build a culture of quality by involving everyone in improvement efforts. The focus remains on meeting customer needs and improving every part of the business.

Kaizen

Kaizen promotes continuous improvement through small, incremental changes. All employees contribute ideas for improvement. Kaizen empowers teams to make ongoing adjustments that lead to better performance. Organizations use Kaizen to foster a culture where everyone seeks ways to improve processes.

PDCA

The PDCA cycle stands for Plan, Do, Check, Act. Teams identify opportunities, plan changes, implement them on a small scale, analyze results, and expand successful changes. PDCA provides a systematic approach to process improvement. Organizations use PDCA to test solutions and refine them over time.

Tip: The PDCA cycle helps teams avoid large-scale failures by testing changes before full implementation.

BPR

Business Process Reengineering (BPR) involves redesigning core business processes to achieve dramatic improvements. Teams analyze workflows and rethink how work gets done. BPR suits organizations that need major changes rather than small adjustments. The goal is to achieve significant gains in efficiency and effectiveness.

Methodology | Defining Characteristics | Core Focuses |

|---|---|---|

Six Sigma | Framework to maximize process quality by minimizing defects and variability. | Process improvement and quality control. |

Lean | Systematic elimination of waste and focus on value creation. | Streamlined operations and waste reduction. |

TQM | Management system focusing on customer satisfaction and continual improvement. | Customer-first approach and total employee participation. |

Kaizen | Continuous improvement through small, incremental changes. | Empowering all employees to contribute to improvement. |

PDCA | Cycle for continuous improvement: Plan, Do, Check, Act. | Systematic approach to process improvement. |

BPR | Radical redesign of business processes for dramatic improvement. | Major efficiency and effectiveness gains. |

How to Choose the Right Methodology

Organizations select Business Process Improvement Methodologies based on their specific needs. Teams consider factors such as the level of change required, the focus area, and available resources. For example, Lean works best for minimizing waste and maximizing value, while Six Sigma fits data-driven process improvement. TQM and Kaizen encourage employee involvement and continuous improvement. PDCA offers a systematic way to test and refine changes. BPR suits organizations seeking major transformations.

A successful selection process often includes:

Reviewing current challenges and goals

Assessing readiness for change

Involving key stakeholders

Matching methodology strengths to organizational needs

Business Process Improvement Methodologies provide a path to better performance. Organizations benefit by choosing the approach that aligns with their objectives and culture.

Identify Processes

Business Process Improvement Methodologies begin with identifying which processes need attention. Teams focus on areas that have the greatest impact on performance, cost, or customer satisfaction. Selecting the right processes sets the foundation for successful improvement.

Select Key Areas

Teams use specific criteria to choose high-impact processes. They look for problem areas by gathering employee feedback, reviewing performance metrics, and conducting process audits. Mapping existing processes helps teams spot redundancies and unnecessary steps. Setting measurable goals ensures that improvements align with business strategy and can be tracked over time.

Criteria | Description |

|---|---|

Identifying Problem Areas | Assessments through employee feedback, performance metrics, and process audits pinpoint inefficiencies or bottlenecks. |

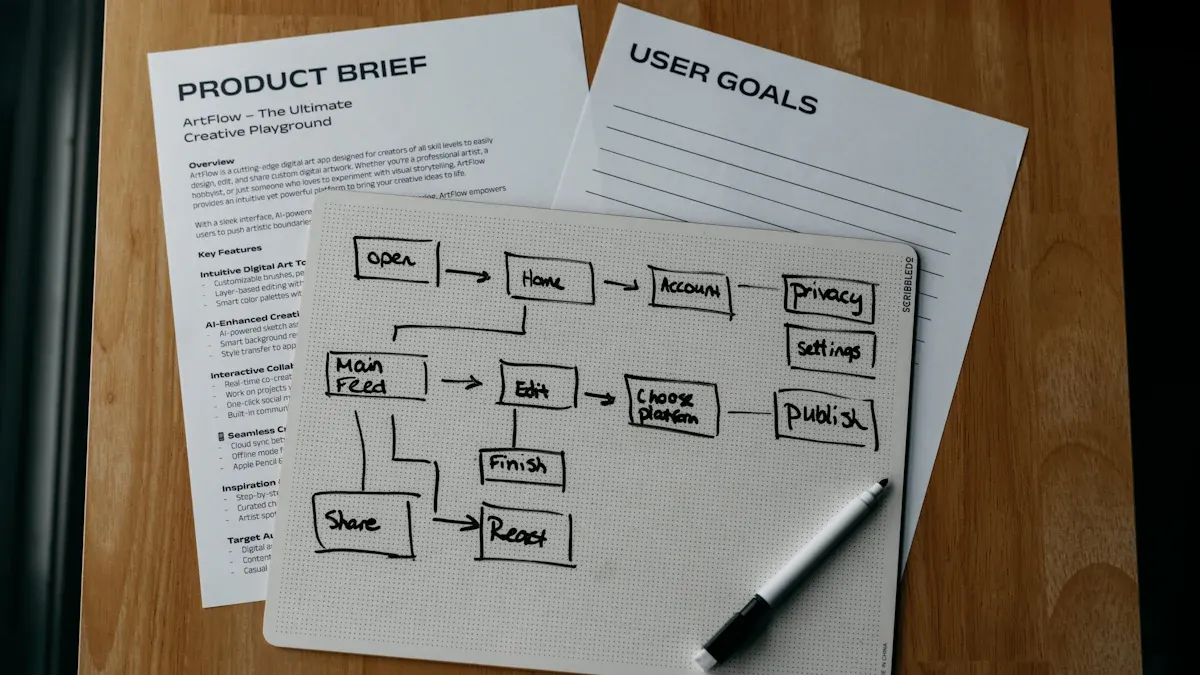

Mapping Existing Processes | Flowcharts or diagrams visually map workflows and highlight redundancies or unnecessary steps. |

Setting Measurable Goals | Clear, quantifiable objectives align with business strategy and allow effective tracking of improvements. |

Teams involve a range of stakeholders in this step. Stakeholders may be internal, such as employees and managers, or external, such as customers and vendors. Including diverse perspectives helps teams understand how processes affect different groups.

Employees

Managers

Shareholders

Customers

Government

Vendors

Project sponsors, team members, and departments directly impacted by the improvement project play key roles. Marketing and sales departments often provide input to ensure that process selection supports business goals. Teams ask questions to identify stakeholders, such as who provides data, who benefits from changes, and who needs to adapt their tasks.

Map Workflows

Mapping workflows gives teams a clear view of how work moves through the organization. Visual tools help teams understand each step and find areas for improvement.

Use Mapping Tools

Teams use a variety of workflow mapping tools to create diagrams and flowcharts. Popular options include:

Lucidchart

ClickUp

MindMeister

Pipefy

Microsoft Visio

Miro

Canva

Smartsheet

Monday.com

Lucidchart offers strong visual mapping features. ClickUp supports collaborative project management. MindMeister helps teams brainstorm and organize ideas. Microsoft Visio integrates with other Microsoft tools for advanced mapping.

Tip: Teams should choose mapping tools that match their needs and technical skills.

Document Steps

Documenting each step of a process provides clarity and transparency. Teams avoid misunderstandings by writing down tasks and responsibilities. Documentation helps transfer knowledge and acts as a training tool for new hires. It supports quality management by highlighting inefficiencies and areas for improvement. Teams use documentation to meet compliance requirements and demonstrate adherence to regulations.

Documentation preserves knowledge within the company.

It provides a standard framework for consistency across teams.

Teams use documentation to track and analyze processes for future improvements.

Clear documentation increases efficiency and productivity by identifying flaws and optimizing workflows.

New hires benefit from improved training and faster onboarding.

Teams clarify roles and responsibilities, preventing confusion and overlapping tasks.

Mapping and documenting workflows help organizations scale success and maintain productivity as they grow. Teams use these steps to build a strong foundation for Business Process Improvement Methodologies.

Analyze Performance

Business Process Improvement Methodologies require teams to analyze performance with a systematic approach. Teams gather data, find inefficiencies, and identify bottlenecks and root causes. This step helps organizations understand where processes break down and how to improve them.

Gather Data

Teams collect several types of data to evaluate process performance. Historical data shows past trends and helps with future planning. Present data gives immediate insights for quick decisions. Inventory data helps businesses manage stock and reduce costs.

Historical Data: Tracks past performance and trends.

Present Data: Offers real-time insights for fast action.

Inventory Data: Optimizes stock levels and controls expenses.

Reliable data collection methods help teams measure efficiency. Surveys reach a wide audience and provide quantitative feedback. Questionnaires offer detailed analysis on specific topics. Interviews give deep insights through open-ended questions. Observations capture real-life behavior and context.

Method | Description | Benefits |

|---|---|---|

Surveys | Broad view of consumer preferences | Reach a larger demographic, gather quantitative data. |

Questionnaires | Structured format for detailed analysis | Allows for focused insights on specific topics. |

Interviews | In-depth qualitative insights through open-ended responses | Facilitates richer dialogue and deeper understanding. |

Observations | Data gathered from actual consumer behavior in real-life scenarios | Captures context and nuances that other methods may overlook. |

Teams also track metrics such as time taken to complete a process, frequency of process completion, and customer satisfaction with outcomes.

Tip: Consistent data collection builds a strong foundation for process analysis.

Find Inefficiencies

Organizations often face inefficiencies that slow down performance. Siloed teams and outdated systems create delays and mistakes. Over-provisioned resources, legacy systems, manual processes, and underutilized software licenses waste time and money. Ineffective collaboration and lack of training also contribute to poor results.

Over-provisioned resources

Legacy systems

Manual processes

Underutilized software licenses

Ineffective collaboration

Lack of skills or training

Manual data entry

Outdated paper-based processes

These problems can impact overall success. Teams must identify and address them to optimize operations.

Bottlenecks

Bottlenecks occur when one part of a process slows down the entire workflow. Teams use several steps to find bottlenecks:

Visualize workflows with flowcharts or BPM tools.

Analyze performance data, such as cycle time and throughput.

Gather input from frontline teams through surveys and interviews.

Conduct workflow diagnosis using fishbone diagrams and audits.

Use real-time monitoring tools like dashboards.

Run ‘what-if’ simulations to test changes.

Process fragmentation across departments and manual data handling often cause bottlenecks. Teams must address these issues to improve flow.

Root Causes

Root causes are the underlying reasons for inefficiencies. Teams look beyond surface problems to find what drives delays and errors. They use tools like fishbone diagrams and regular audits to diagnose issues. By understanding root causes, organizations can design solutions that prevent future problems.

Business Process Improvement Methodologies guide teams through data collection, analysis, and problem-solving. This approach helps organizations achieve lasting improvements.

Design Solutions

Choose Methodology

Selecting the right business process improvement methodology depends on several factors. Teams must align the chosen approach with their specific goals, organizational culture, and available resources. For example, Lean principles help optimize process flow and reduce waste, while Six Sigma targets high-quality outcomes and minimizes process variation. Total Quality Management (TQM) fosters a culture of continuous improvement across all departments. Some organizations combine methodologies or customize them to address unique challenges.

Factor | Explanation |

|---|---|

Match goals | Align the methodology with specific objectives, such as speed or quality. |

Check culture | Consider if the methodology fits the organizational culture, like Kaizen. |

Evaluate complexity | Assess if the methodology can handle the complexity of the processes. |

Review resources | Ensure the organization has the necessary resources for the chosen method. |

Consider timelines | Choose a methodology based on the urgency of improvements needed. |

Teams often evaluate implementation complexity, resource requirements, and expected outcomes before making a decision. They analyze current needs and may adopt hybrid approaches to maximize results.

Tip: Organizations should assess their goals, resources, and culture before selecting a methodology. This ensures the chosen approach fits the problem and leads to sustainable improvements.

Plan Improvements

After choosing a methodology, teams design actionable and measurable plans. They start by analyzing current processes, identifying bottlenecks, and gathering data on performance metrics such as customer wait times, inventory turnover rates, and staff productivity.

Set Objectives

Setting clear objectives helps teams track progress and measure impact. Goals must align with business priorities for long-term success. Teams use SMART goals—specific, measurable, achievable, relevant, and time-bound—to link strategy with results. For example, a team may aim to reduce production waste by 20% within six months.

Establish clear, well-defined goals.

Align improvements with business objectives.

Organizations should communicate the reasons behind changes to involve employees and build engagement. Effective change management prevents resistance and keeps teams motivated.

Prioritize Actions

Prioritizing actions ensures that teams focus on the most impactful improvements first. Best practices include:

Process Optimization: Streamline workflows and eliminate redundant steps.

Resource Management: Use time, money, and human capital effectively.

Quality Control: Implement systems to prevent errors and maintain standards.

Innovation Integration: Adopt new technologies and methods to enhance operations.

Teams manage the introduction of new systems carefully. They communicate changes clearly and involve employees in the process. This approach builds support and helps organizations achieve lasting results.

Note: Prioritizing actions and setting measurable objectives create a roadmap for successful business process improvement.

Implement Changes

Execute Plan

Teams move from planning to action by following a clear sequence of steps. They start by identifying goals and objectives for the process improvement. Next, they map out the process to understand each step. Teams analyze current procedures and spot opportunities for improvement. They develop strategies to address pain points and redesign workflows. After finalizing the plan, teams implement changes and monitor progress.

Steps for effective execution:

Map out the process.

Analyze and find opportunities.

Develop improvement strategies.

Implement changes.

Monitor and measure progress.

Refine and improve as needed.

During implementation, teams often face challenges. Common obstacles include resistance to change, poor communication, and lack of leadership support. Employees may feel uncomfortable with new routines. Inadequate training can slow down adoption. Teams must plan carefully and communicate clearly to overcome these barriers.

Challenge | Description |

|---|---|

Resistance to Change | Employees may prefer old routines and push back against new processes. |

Inadequate Communication | Poor communication leads to misunderstandings and lack of trust. |

Insufficient Leadership Support | Without strong leadership, change initiatives may struggle. |

Poor Planning and Execution | Weak planning can cause missed deadlines and budget issues. |

Cultural Barriers | A culture resistant to change can block new processes. |

Lack of Employee Engagement | Low engagement may result in employees reverting to old habits. |

Inadequate Training and Support | Without proper training, employees may struggle to adapt. |

Failure to Sustain Change | Ongoing effort is needed to maintain improvements. |

Tip: Teams should provide training and support to help employees adapt to new processes.

Monitor Progress

Tracking progress ensures that changes deliver the expected results. Teams use specific metrics to measure efficiency, financial impact, customer satisfaction, employee engagement, compliance, and continuous improvement.

Track Metrics

Teams select metrics that match their goals. They monitor cycle time, error rates, and resource utilization to measure process efficiency. Financial impact is tracked through cost savings and revenue generation. Customer satisfaction is measured using feedback, surveys, and retention rates. Employee engagement is assessed by satisfaction scores and productivity. Compliance and risk metrics help teams meet regulations. Continuous improvement metrics show how well teams sustain and scale changes.

Metric Type | Metrics |

|---|---|

Process Efficiency | |

Financial Impact | Cost Savings, Revenue Generation |

Customer Satisfaction | Feedback, Surveys, Retention, Support Metrics |

Employee Engagement | Satisfaction, Motivation, Training, Productivity |

Compliance and Risk Mitigation | Regulatory Compliance, Risk Management |

Continuous Improvement | Improvement Pipeline, Sustainability, Scalability |

Note: Regular tracking helps teams spot issues early and adjust strategies.

Adjust as Needed

Teams review progress at scheduled intervals. They check if changes meet target metrics and assess resource utilization. Teams look for new opportunities to improve. If results fall short, teams refine processes and make adjustments.

Aspect of Review | Frequency Recommendation |

|---|---|

Progress against target metrics | At scheduled intervals |

Effectiveness of implemented changes | At scheduled intervals |

Resource utilization | At scheduled intervals |

New improvement opportunities | At scheduled intervals |

Teams maintain flexibility and respond quickly to feedback. They update plans and retrain employees when needed. This approach helps organizations sustain improvements and achieve long-term success.

Teams that monitor progress and adjust strategies build a culture of continuous improvement.

Sustain Improvements

Embed Changes

Organizations must embed process improvements into their culture to achieve lasting results. Teams use several strategies to make changes stick. Leadership commitment plays a key role. Leaders participate actively and set clear expectations. Open communication channels encourage employees to share ideas and feedback. Training and development equip staff with the skills needed for new processes. Recognition and rewards motivate employees to continue improving. Structured methodologies, such as the PDCA cycle, provide a systematic approach for ongoing enhancements.

Leadership commitment strengthens the importance of improvements.

Communication builds transparency and trust.

Training and development increase employee participation.

Recognition and rewards encourage ongoing engagement.

Structured methodologies guide teams through each improvement step.

Teams focus on small incremental changes to build momentum. Solving low-cost problems removes financial barriers. Regular reviews and monitoring help teams adjust strategies as needed. Celebrating successes keeps motivation high. Establishing a process-based culture ensures that continuous improvement becomes a core value.

Note: Embedding changes requires consistent effort from all levels of the organization.

Scale Success

Organizations scale successful process improvements by standardizing operations and empowering local teams. They create detailed standard operating procedures (SOPs) and centralized training programs. Regular audits help maintain consistency. Strong local managers set clear key performance indicators (KPIs) and adapt processes to fit local needs. Technology streamlines operations through centralized systems for inventory management, customer relationship management (CRM), and automated reporting.

Training

Training supports scaling by ensuring that employees understand new processes. Centralized training programs teach best practices across all locations. Teams use SOPs to guide daily tasks. Ongoing training keeps skills up to date and prepares staff for future changes.

Training Strategy | Benefit |

|---|---|

Centralized programs | Consistent knowledge across locations |

SOPs | Clear guidance for daily operations |

Ongoing development | Prepares teams for future improvements |

Tip: Regular training sessions help teams maintain high standards and adapt to new systems.

Leadership Support

Leadership support drives successful scaling. Leaders hire strong managers and set clear KPIs. They encourage local adaptation while maintaining oversight. Leaders communicate progress and celebrate achievements. They invest in localized marketing and gather customer feedback to refine strategies.

Standardize operations across all locations.

Empower local teams with strong managers.

Use technology for centralized management.

Invest in localized marketing and support systems.

Organizations measure the impact of scaling by tracking process time, employee productivity, and customer satisfaction. They monitor financial health and return on investment (ROI). Establishing baselines and goals helps teams evaluate progress. Success depends on clear objectives and ongoing support from leadership.

Teams that embed changes and scale success build a foundation for continuous improvement and long-term growth.

Organizations that follow the five-step roadmap see lasting improvements in efficiency, quality, and customer satisfaction. Clients at systems and teams have achieved these results by gathering data, engaging employees, and monitoring progress. The table below highlights key takeaways:

Key Takeaway | Description |

|---|---|

Data Gathering | Understand current processes and find areas for improvement. |

Employee Engagement | Motivate teams and support positive change. |

Resource Allocation | Optimize productivity and reduce waste. |

Continuous Monitoring | Track KPIs to measure effectiveness. |

Measurable Goals | Align objectives with business strategy. |

To start, organizations can create a personalized checklist:

Set clear, actionable objectives.

Streamline workflows and prioritize initiatives.

Readers can reach out to systems and teams for guidance or share experiences to help others succeed.

FAQ

What is a business process improvement methodology?

A business process improvement methodology gives teams a structured way to analyze, redesign, and optimize workflows. These methods help organizations boost efficiency, reduce waste, and improve quality.

How do teams choose the right methodology?

Teams review their goals, resources, and challenges. They compare options like Lean, Six Sigma, or Kaizen. The best choice matches the organization's needs and culture.

Can small businesses use these methodologies?

Small businesses benefit from process improvement. They start with simple tools like flowcharts or PDCA cycles. These methods help them save time and money.

What tools help map workflows?

Teams use tools such as Lucidchart, Microsoft Visio, and Miro. These platforms create visual diagrams that show each step in a process.

Tip: Visual maps make it easier to spot bottlenecks and inefficiencies.

How do teams measure improvement success?

Teams track metrics like cycle time, error rates, and customer satisfaction. They compare results before and after changes to see progress.

What challenges do teams face during implementation?

Teams often face resistance to change, poor communication, and lack of training. Leaders support employees and provide clear instructions to overcome these challenges.

How often should teams review processes?

Teams review processes regularly, such as every quarter or after major changes. Frequent reviews help maintain improvements and spot new opportunities.

Why is employee involvement important?

Employee involvement brings fresh ideas and helps teams spot problems early. Engaged employees support changes and help improvements last.